Aero Brushed Aluminum Sheets - RAL Color PPGL/PPGL Steel Coil /PPGL Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

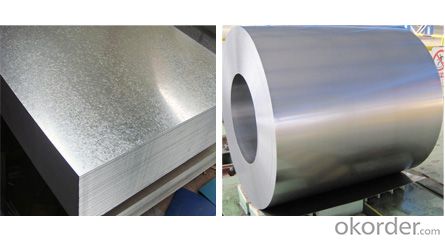

RAL Color PPGL/PPGL Steel Coil /PPGL coil

Main Features of RAL Color PPGL/PPGL Steel Coil /PPGL coil

Standard: AISI, ASTM, BS, GB, JIS, AISI,ASTM,BS,DIN,GB,JIS

Thickness: Customized, 0.12-2.0MM

Model Number: Q235/Q195/JISG/SPCD

Type: Steel Coil, Steel coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Application: Boiler Plate

Structure of RAL Color PPGL/PPGL Steel Coil /PPGL coil :

Special Use: High-strength Steel Plate

Width: Customized, 600-1250mm

Length: Customized

Grade: SGCC, SPCC, DC51D, SGHC,A653

Surface treatment: Galvanized

Zinc coating: 60-275g/sqm

HRB: 65-95

Coil weight: 3-10/MT

Tolerance: thickness+/-0.01mm

FQA

How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every pipe before delivered out. If you want to see our quality certifications and all kinds of testing report, please just ask us for it.

Advantage:

Chose happens because of quality, then price, we can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents),

Quick goods delivery, our factories locate near the seaport, which is very convenient for transportation.

Products Description for RAL Color PPGL/PPGL Steel Coil /PPGL coil:

Raw material:SGCC,SPCC,DC51D, SGHC,A653,201,202,321,301,302,304,304L,316,316L,310,310S,409,410,430,439,443,445,441 and so on

Certificate:ISO9001.ISO14001.OHSAS18001

Grade:SGCC, CGCC, SPCC, ST01Z, DX51D, A653

Pictures:

- Q: 1 ton of aluminium=______ tons of Alumina

- After analyzing the solutions I felt i'd desire to describe a sprint extra what others have not mentioned. constantly examine what the producer prints out on the label the two interior the door jam or glove container as to the finished available weight the truck can carry. Payload (weight it could carry) and towing potential (weight it could tow) are 2 a number of issues. additionally, maximum one ton vehicles can carry extra beneficial than a ton. as an occasion: If the vehicles GVWR gross motor vehicle weight score is 12000 lbs. and the truck weighs 7000 lbs, then you rather can haul 5000 lbs. this is human beings, gas, shipment, each thing. keep in mind, this is the optimal. GCWR Gross blended weight score is that of the truck and towing motor vehicle. If as an occasion this is 15000 lbs, and your truck weighs 7000lbs. then you rather are turning out to be an empty truck and tow as much as 8000 lbs. on the lighter edge, a million/2 ton %. united statesgeneraly are purely that--one thousand to 1900 lbs. 3/4 ton are a sprint extra and would have a camper kit as nicely. One plenty are stable for flatbeds, and the terminology is purely that--a generalization. stable success, and look for the placard.

- Q: as for heating coil and aluminum sheet, which one is better for heating?

- Both of them have advantage. It depends on the new product type it’s applied. Heating coil: it’s applied in some products with high temperature and large heat release, such as oven and other types.

- Q: Can aluminum sheets be welded or soldered?

- Yes, aluminum sheets can be welded or soldered.

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum is a lightweight material, making it ideal for use in vehicles as it helps reduce fuel consumption and increase overall efficiency. This is particularly important for industries such as aviation and automotive, where weight reduction is a key factor in improving performance. Secondly, aluminum has excellent corrosion resistance properties. This is crucial in the transportation industry, where vehicles are exposed to various environmental conditions such as rain, snow, and road salt. Using aluminum sheets helps to extend the lifespan of vehicles and reduces maintenance costs associated with corrosion-related issues. Additionally, aluminum is highly recyclable, making it a more sustainable choice compared to other materials. The transportation industry is increasingly focusing on sustainability, and the use of aluminum sheets aligns with these goals. Recycling aluminum requires significantly less energy compared to producing it from raw materials, leading to reduced carbon emissions and energy consumption. Moreover, aluminum offers excellent formability and versatility. It can be easily molded into various shapes and sizes, allowing manufacturers to design lightweight yet strong structures. This flexibility in design enables the production of more aerodynamic vehicles, leading to improved fuel efficiency. Lastly, aluminum sheets have high strength-to-weight ratio, meaning they can provide the required strength while still being lightweight. This property makes aluminum an ideal material for applications that require strength and durability, such as vehicle bodies, chassis, and structural components. Overall, the advantages of using aluminum sheets in the transportation industry include weight reduction, corrosion resistance, sustainability, formability, versatility, and high strength-to-weight ratio. These benefits contribute to improved performance, fuel efficiency, and durability of vehicles, making aluminum an excellent choice for various transportation applications.

- Q: What are the different methods of cutting aluminum sheets?

- To cut aluminum sheets, one can utilize various methods based on specific requirements and material thickness. Some commonly employed techniques include: 1. Shearing: By means of a shearing machine, straight lines can be cut in the aluminum sheet. The machine applies force to a blade, resulting in material separation. Shearing is a swift and efficient approach, especially suitable for thinner gauges. 2. Sawing: For cutting aluminum sheets, circular or bandsaws equipped with specialized metal-cutting blades are commonly employed. This method allows for greater precision and controlled cuts, making it ideal for thicker sheets. 3. Laser cutting: This highly precise and efficient technique employs a concentrated beam of light to melt and vaporize the aluminum, resulting in a clean and smooth cut. Laser cutting is particularly advantageous for intricate designs and complex shapes. 4. Waterjet cutting: This method involves the use of a high-pressure stream of water mixed with abrasive particles to cut through aluminum sheets. It is applicable to various thicknesses and allows for precise cuts without generating heat. Waterjet cutting is often preferred for thicker sheets or when high precision is required. 5. Plasma cutting: By employing a high-temperature plasma torch, aluminum sheets can be melted and cut. The torch generates an electric arc, ionizing the gas and creating a plasma state. Although versatile and capable of cutting through different thicknesses, plasma cutting may yield rougher edges in comparison to laser or waterjet cutting. When selecting the most suitable method for cutting aluminum sheets, it is crucial to consider project-specific requirements such as desired cut quality, speed, and complexity.

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- Some of the different surface finishes for aluminum sheets in the aerospace industry include mill finish, anodized finish, brushed finish, and painted finish. These finishes are applied to enhance the appearance, durability, corrosion resistance, and overall performance of the aluminum sheets in aerospace applications.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed. Roll forming is a process in which a continuous strip of metal, in this case, aluminum, is fed through a series of rollers to gradually shape it into a desired profile or shape. Aluminum is an ideal material for roll forming due to its malleability and ductility, allowing it to be easily bent, curved, and formed into various shapes. It is commonly used in industries such as construction, automotive, and aerospace for applications that require lightweight yet durable components.

- Q: Are the aluminum sheets suitable for manufacturing heat exchangers?

- Yes, aluminum sheets are suitable for manufacturing heat exchangers. Aluminum is a lightweight and highly conductive material, making it an ideal choice for heat transfer applications. Its excellent thermal conductivity allows for efficient heat transfer, resulting in effective cooling or heating processes. Additionally, aluminum is corrosion-resistant, which is crucial for heat exchangers that come in contact with various fluids. The malleability and formability of aluminum sheets also make them easy to shape into the required designs for heat exchanger components. Overall, aluminum sheets offer several advantages for manufacturing heat exchangers, making them a suitable choice for this application.

- Q: How does the formability of aluminum sheet vary with different alloys?

- Variations in chemical composition and mechanical properties result in significant differences in the formability of aluminum sheet among different alloys. To enhance specific characteristics like strength, corrosion resistance, and formability, aluminum alloys are typically combined with elements such as copper, manganese, magnesium, and zinc. Aluminum alloys like the 1xxx series (pure aluminum) and the 3xxx series (manganese alloyed) are highly formable and commonly used for deep drawing applications. These alloys can be shaped into complex forms without cracking or tearing. In contrast, alloys with higher strength properties, such as the 2xxx series (copper alloyed) and the 7xxx series (zinc alloyed), generally have reduced formability. Although these alloys are often used in structural applications where strength is crucial, they require careful handling and processing to avoid defects during forming. Alloys in the 5xxx series (magnesium alloyed) offer a good balance of formability and strength. They are widely used in industries like automotive and aerospace, as they can be easily formed into different shapes while providing sufficient strength and corrosion resistance. It's important to note that the formability of aluminum sheet is not solely determined by the alloy composition. Other factors such as sheet thickness, forming temperature, and the specific forming process employed (e.g., deep drawing, bending, stretching) also influence formability. These factors interact with alloy properties to affect the formability characteristics of aluminum sheet. Therefore, careful selection of the appropriate alloy and process parameters is essential to achieve the desired formability for specific applications.

Send your message to us

Aero Brushed Aluminum Sheets - RAL Color PPGL/PPGL Steel Coil /PPGL Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords