Color Coated PPGI/PPGL Steel Coil or Steel Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. PPGI/PPGL Steel Sheets/Coil Description:

With Galvanized as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Sheets/Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

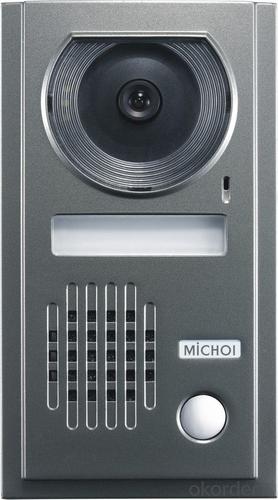

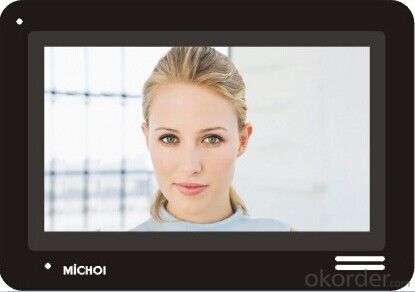

3.PPGI/PPGL Steel Sheets/Coil Images

4.PPGI/PPGL Steel Sheets/Coil Specification

Standard: SAE, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D ,DX53D

Thickness: 0.17-2.3mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-6tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of PPGI/PPGL Steel Sheets/Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the maximum thickness of steel coils?

- The maximum thickness of steel coils can vary depending on the specific application and manufacturing process. However, in general, steel coils can have a maximum thickness ranging from a few millimeters to several centimeters. The thickness is typically determined by factors such as the intended use of the steel coils, the type of steel being used, and the capabilities of the manufacturing equipment.

- Q: What are they worth today? As well as a 1943 steel nickel?

- I think they are worth about a pennie.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- How grimy is your range? I actually have a stainless range and all I do is discover a soapy sponge on it, with dish cleansing soap. I get rid of each and all of the knobs and burners approximately as quickly as a week (and every time I fry something and splatter oil everywhere, yet i attempt to disguise issues with foil as quickly as I fry to sidestep a multitude). It takes possibly 5 minutes to scrub my range because I shop it clean and not in any respect, ever use it if it has spills on it. i've got found out via the years to wipe issues up right now, or the spills get baked on and become very confusing to get rid of. My range is electrical powered, so I take off the electrical powered burners and gently wash those with a soapy sponge too (I carry them and rub the soapy sponge on them, then carry them below the faucet to rinse, without getting the plug in factor section moist). My range continues to be very clean this way, and that i take advantage of the rougher side of a non-scratch sponge for something that desires some scrubbing. in the experience that your range has undesirable stains caught on it, you ought to use very, very advantageous metallic wool on it. An SOS pad will paintings, do in basic terms no longer rub too problematic or you will take off the shine from the range. SOS pads are ok on each and all of the immaculate areas of the range. whilst completed washing it, take a humid dish towel and wipe each and all of the cleansing soap off, then dry the range and it will seem large.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized, galvannealed, and organic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvannealed coatings involve a two-step process where the steel is first galvanized and then heated to form an alloyed surface layer, offering enhanced paint adhesion and weldability. Organic coatings, on the other hand, use paints or other protective coatings to provide corrosion resistance and aesthetic appeal.

- Q: I'm missing the arguement, and I've seen another question like this... but the steel toe issue has 2 scenario's right?... Let me label them out, the 2nd is the one that no one talks about?Note to anyone - how are your catapillar boots, your wolverines, and then your cheap walmart/sears brands?1. Steel toe on, toes get cut off because of something falling on them. OUCH!.. Reattach perhaps?2. This one is what I question. No steel toe, large object falls on toes. SMASH... Pudding in your shoes.Wouldn't it be safer to say you'de be better off with a steel toe?

- Go to Discovery channel and look up Mythbusters episode on steel toed boots. It will surprise you what they can take, even with dropped items. They could get some damage, but never a severance.

- Q: I need to know how you rate the hardness of steel any ideas?

- Find your portable hardness testers from our latest collections thats for sure having the ability to test hardness of metal alloys and plastic by applying some amount of pressure on it. All our evaluators can evaluate in Brinell, Rockwell and Vickers machines.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- It is because Broken Steel doesn't add a new quest. It continues the main story. Once you beat the game, you will see. There is nothing wrong with it.

- Q: How do steel coils contribute to energy efficiency in transportation?

- Steel coils are essential in energy-efficient transportation due to their lightweight yet strong nature. The use of steel coils in vehicles, such as cars and trucks, reduces the overall weight of the vehicle, enhancing fuel efficiency and reducing carbon emissions. Additionally, steel coils are often used in rail transportation, where their durability and strength contribute to the energy efficiency of trains by allowing for higher speeds and improved load carrying capacity.

- Q: I heard that the stores don't sale Steel Legion anymore...Is this true..Also I want to know why they cost more than regular Imperial Guardsmen..Such as Cadian...Do they have something Special?Also what do I need to buy to have a complete Steel Legion army..I need two squads of troops of 20's?and two sergeants for each squad.and one commiser?Well I;m guessing..someone please help...I havent played in about 4 years.

- The stock at various shops may vary, but you can buy Steel Legion miniatures through the mail order, or the Internet from GW. Cadian troopers are plastic, There are no plastic Steel Legion troops. The plastic models are (a tiny bit) not so horribly expensive as the metallic ones. The minimum requirements for your force vary from mission to mission, but a good start is 1 HQ unit 2 Troop choices. Also, the total points cost of the battle is to be considered. (Usually 500, 1000, or 1500 points.) What you described is one possible choice, although the size of IG squads is 10 and not 20. And you must include a command squad, the commissar is optional. You might change the other 20 troops for a tank, or a squad of Sentinels. Happy gaming!

- Q: How are steel coils used in the appliance industry?

- Steel coils are commonly used in the appliance industry for various purposes such as manufacturing washing machines, refrigerators, dishwashers, and other household appliances. These coils are typically used to form the structure of the appliances, provide strength and durability, and support the weight of various components. The steel coils are also used in the production of heating elements, motors, and other key components that ensure the efficient operation of appliances.

Send your message to us

Color Coated PPGI/PPGL Steel Coil or Steel Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords