Color Coated Galvanized Steel Coil/PPGL Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color Coated Galvanized Steel Coil/PPGL Roofing Sheets

1. Detailed Specifications:

| Product | Color Coated Galvanized Steel Coil/PPGL Roofing Sheets |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application of Color Coated Galvanized Steel Coil/PPGL Roofing Sheets

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

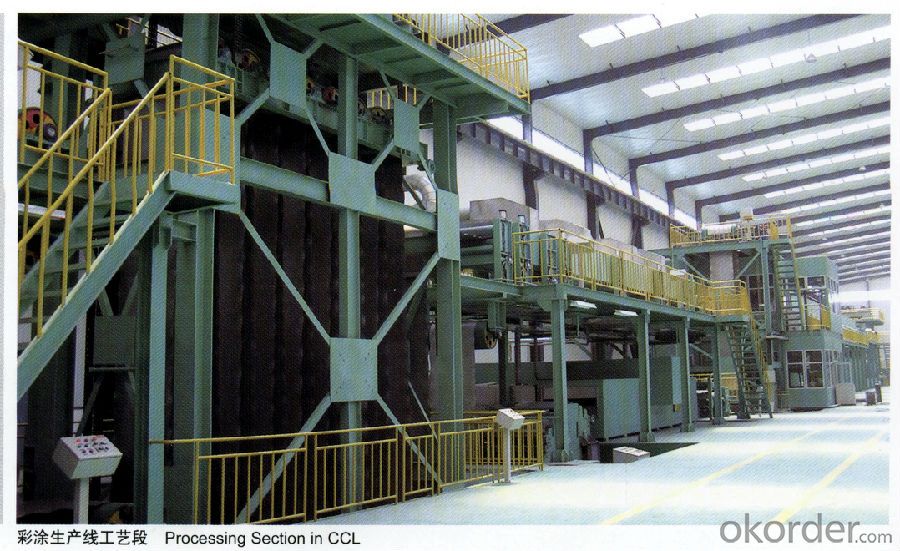

3. Color Coated Galvanized Steel Coil/PPGL Roofing Sheets Image:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils used in the manufacturing of electrical transformers?

- Steel coils are used in the manufacturing of electrical transformers as they serve as the core of the transformer. The coils are wound around the steel core to create an electromagnetic field that efficiently transfers electrical energy from one coil to another. The steel coils help to increase the magnetic flux and enhance the efficiency of the transformer, allowing for the transformation of electrical voltage levels.

- Q: Im going to buy T-304 Stainless Steel exhaust tips for my truck. Is T-304 Stainless Steel good metal?

- Stainless steel is available in 2 grades - 304 and 316. The 304 has traces of ferrous to make it adaptable for the intended purpose. The 316 is non-ferrous and a bit more expensive. Whereas the 316 will not inhibit rust, the 304 will show some flecks (which can be cleaned away) over a period of time. It, however, is as good as the other.

- Q: How are steel coils used in the production of wind turbine components?

- Steel coils are an essential component in the production of wind turbine components. These coils are typically made from high-strength steel, which is known for its durability and ability to withstand harsh weather conditions. One of the primary uses of steel coils in wind turbine production is in the manufacturing of the tower. The tower is the structure that supports the entire wind turbine, and it needs to be strong enough to withstand the weight of the nacelle and the rotor blades. Steel coils are used to fabricate the sections of the tower, which are then assembled to create a tall and sturdy structure. Another crucial application of steel coils is in the production of the rotor blades. The rotor blades are responsible for capturing the wind's energy and converting it into rotational motion. Steel coils are used in the manufacturing of the blade's internal structure, known as the spar, which provides strength and rigidity to the blade. The coils are shaped and formed into the desired blade shape, and then composite materials are added to enhance its aerodynamic properties. Furthermore, steel coils are also utilized in the production of other wind turbine components such as the hub and the nacelle. The hub is the central part of the rotor, to which the blades are attached, and it requires a strong and reliable steel structure to sustain the immense forces generated by the rotating blades. The nacelle, on the other hand, houses the generator and other vital components of the wind turbine, and steel coils are used in its construction to ensure stability and protection. In summary, steel coils play a crucial role in the production of wind turbine components. From the tower to the rotor blades, hub, and nacelle, steel coils provide the necessary strength, durability, and stability required to withstand the demanding conditions of wind energy production. Without these coils, the construction and operation of wind turbines would not be possible, as they form the backbone of these renewable energy systems.

- Q: What are the common coil surface treatments?

- Some common coil surface treatments include galvanizing, painting, and powder coating. These treatments help protect the coil from corrosion, improve its appearance, and increase its durability.

- Q: How are steel coils processed and shaped into different products?

- Different products are manufactured from steel coils through a series of manufacturing processes. The initial step is referred to as uncoiling, which entails the unwinding and straightening of the steel coil. Typically, this is achieved by feeding the coil through a machine called a decoiler. Once the coil is uncoiled, it proceeds to the leveling process. The objective of this step is to eliminate any unevenness or warping in the steel. The coil is passed through a set of rollers that exert pressure and flatten the steel to achieve the desired thickness. This ensures that the steel is uniform and prepared for further processing. Following the leveling process, the steel is usually cut into smaller pieces or sheets. Machines such as shears or slitters are employed for this purpose, enabling the steel to be cut into various widths or lengths. The specific dimensions depend on the requirements of the particular product being manufactured. After the steel is cut, it can undergo additional shaping processes. One commonly used method is roll forming, in which the steel is gradually shaped into the desired profile by passing it through a series of rollers. This technique is frequently utilized in the production of roofing sheets, wall panels, or beams. Another widely used shaping process is stamping. In stamping, the steel is pressed between a die and a punch to create intricate shapes or patterns. This method is commonly employed in the automotive industry for the production of components such as car body panels or engine parts. In addition to shaping, the steel may also undergo surface treatments or coatings to enhance its properties or improve its appearance. This can involve processes like galvanizing, where a layer of zinc is applied to safeguard the steel against corrosion, or painting to provide a decorative finish. In conclusion, the process of shaping steel coils into different products encompasses a combination of cutting, shaping, and surface treatments. These processes are meticulously executed to ensure that the steel meets the required specifications and is suitable for use in various industries.

- Q: engineering sloutions related to steel fabrication

- not okorder /

- Q: How do steel coils affect the quality of finished products?

- Steel coils can greatly impact the quality of finished products in various industries. One of the key ways steel coils affect product quality is through their dimensional accuracy and consistency. When the steel coils are not properly manufactured or have irregular dimensions, it can lead to issues in the production process and result in finished products that do not meet the desired specifications. Furthermore, the surface quality of steel coils is critical in determining the final appearance and performance of the finished products. Coils with surface defects, such as scratches, rust, or unevenness, can negatively impact the aesthetic appeal of the products, making them less desirable to customers. Moreover, these defects can also affect the functionality and durability of the finished products, leading to potential failures or reduced lifespan. The mechanical properties of steel coils also play a vital role in determining the quality of finished products. Coils with inconsistent or inadequate mechanical properties can compromise the strength, toughness, and overall performance of the end products. For example, in industries such as automotive or construction, where strength and reliability are crucial, the use of steel coils with the wrong mechanical properties can lead to safety hazards or structural failures. Additionally, the chemical composition of steel coils can significantly influence the quality of finished products. The presence of impurities or variations in the alloying elements can affect the material's corrosion resistance, weldability, and other essential properties. This, in turn, can impact the longevity and functionality of the final products. In summary, steel coils have a substantial impact on the quality of finished products. Their dimensional accuracy, surface quality, mechanical properties, and chemical composition all contribute to the overall performance, appearance, and durability of the end products. Therefore, it is crucial to ensure that steel coils used in manufacturing processes meet the desired standards to achieve high-quality finished products.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils are both widely used in various industries for their strength and durability. However, there are some key differences between the two that should be considered when choosing the appropriate material for a specific application. One of the main distinctions between steel coils and stainless steel coils is the composition of the materials. Steel coils are made primarily of iron and carbon, with other elements added to enhance specific properties. On the other hand, stainless steel coils are made of iron, carbon, and a significant amount of chromium, which gives them their unique corrosion-resistant properties. Due to the presence of chromium, stainless steel coils offer superior resistance to corrosion, tarnishing, and rust compared to regular steel coils. This makes stainless steel coils particularly suitable for applications in environments with high humidity, moisture, or exposure to corrosive substances. In contrast, steel coils are more prone to rust and may require additional protective coatings or treatments to prevent corrosion. Another significant difference is the appearance of the two materials. Stainless steel coils have a shiny and reflective surface, giving them an aesthetically pleasing look. They are commonly used in applications where appearance is important, such as kitchen appliances, architectural structures, or decorative purposes. Steel coils, on the other hand, have a matte or dull finish and are often used in industrial applications where appearance is not a primary concern. In terms of strength, both steel and stainless steel coils offer excellent mechanical properties. However, stainless steel coils generally exhibit higher tensile strength and greater resistance to high temperatures. This makes them suitable for applications that require strength, such as construction, automotive, or aerospace industries. Lastly, cost is a factor that should be considered when comparing steel coils to stainless steel coils. Steel coils are generally more cost-effective than stainless steel coils due to the lower cost of raw materials and simpler manufacturing processes. However, when the added value of corrosion resistance and longevity is taken into account, stainless steel coils may prove to be a more economical choice in the long run, as they require less maintenance and replacement. In conclusion, steel coils and stainless steel coils have different properties and characteristics that make them suitable for specific applications. Stainless steel coils offer superior corrosion resistance, a shiny appearance, and higher tensile strength, while steel coils are more cost-effective. The choice between the two ultimately depends on the specific requirements of the application, such as the environment, aesthetics, strength, and budget.

- Q: My uncle got me some new 'Nam style jungle boots at the px at Fort Worth JSB, and he told me that back in Vietnam, they used to issue guys steel sole boots, that had a sole reinforced with a steel plate, as punji stick d-fence. Is this true, it sounds logical, but I can't figure out how a steel plate in the sole would work. My uncle is kind of a BS'er, plus he wasn't even in Vietnam, much less the Infantry, much less combat, but he was in USAF at the time.

- Steel Sole Boots

- Q: What are the different methods of blanking steel coils?

- There are multiple techniques utilized for blanking steel coils, including: 1. Shearing: To achieve the desired size and shape, shearing involves cutting the steel coil using a shear or a set of shears. This method is commonly used as it is fast and cost-effective, particularly suitable for thin to medium-thickness steel coils. 2. Laser cutting: Employing a high-powered laser beam, laser cutting is a precise and efficient method for cutting through steel coils. It is ideal for complex shapes and thick steel coils, providing clean and accurate cuts. Consequently, it is favored for high-quality blanking. 3. Waterjet cutting: A versatile method, waterjet cutting employs a high-pressure stream of water mixed with an abrasive material to cut through steel coils. It generates no heat and can cut through various materials, including steel. It is particularly suitable for cutting thick steel coils and intricate shapes and designs. 4. Stamping: This method involves pressing a die into the steel coil to cut out the desired shape. It is commonly used for high-volume production as it can rapidly cut multiple pieces simultaneously. Stamping is suitable for cutting simple shapes and is often combined with other processes, such as shearing or laser cutting, for more complex shapes. 5. Plasma cutting: Plasma cutting utilizes a high-velocity jet of ionized gas to cut through the steel coil. It is suitable for cutting thick steel coils and can handle a wide range of materials. Known for its speed and versatility, plasma cutting is a popular method for blanking steel coils. These methods of blanking steel coils offer various benefits depending on project requirements, such as speed, precision, complexity of shapes, and material thickness. The selection of the method relies on factors like cost, production volume, desired quality, and turnaround time.

Send your message to us

Color Coated Galvanized Steel Coil/PPGL Roofing Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords