Adhesive Backed Aluminum Foil Sheets - Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Sheet 1070

Alloy Number | AA1050 , AA1060 ,AA1070 ,AA1100 etc. |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Sheet 1070

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3 Packaging & Delivery of Aluminum Sheet 1070

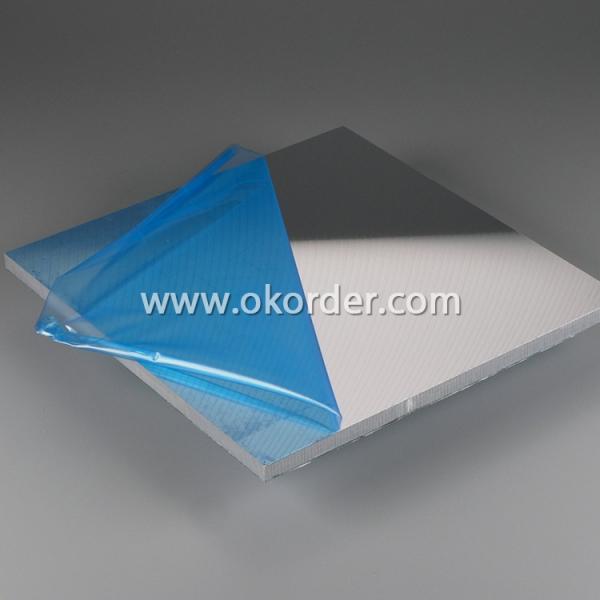

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Aluminum Sheet 1070

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: What specific considerations or precautions should be taken into account when using aluminum sheets in environments with high moisture levels?

- <p>When using aluminum sheets in damp or wet environments, it's important to consider the potential for corrosion. While aluminum is generally corrosion-resistant due to its protective oxide layer, it can still be susceptible to certain types of corrosion in the presence of moisture, especially if the environment is acidic or saline. It's crucial to use high-quality aluminum alloys that are designed for such conditions. Additionally, proper surface treatment such as anodizing or applying protective coatings can enhance resistance to corrosion. Regular inspections and maintenance are also recommended to check for signs of corrosion and to address any issues promptly.</p>

- Q: Are aluminum sheets suitable for electrical enclosures?

- Aluminum sheets are indeed suitable for electrical enclosures. With their lightweight and durable composition, they possess excellent conductivity and resistance to corrosion. Furthermore, their exceptional heat dissipation capabilities make them perfect for enclosures that house electrical components. Additionally, aluminum is easily manipulated, allowing for customization in terms of shape and size. To enhance their resistance to environmental elements such as moisture, dust, and chemicals, aluminum sheets can be coated or anodized. Overall, aluminum sheets offer a dependable choice for electrical enclosures, providing both electrical and mechanical properties while ensuring the protection of sensitive electrical equipment.

- Q: Can aluminum sheets be used for electrical conductors?

- Yes, aluminum sheets can be used for electrical conductors. Aluminum is a good conductor of electricity, although it is not as efficient as copper. However, aluminum is often used in electrical applications due to its lightweight nature, cost-effectiveness, and corrosion resistance. It is commonly used in power distribution lines, wiring systems, and electrical equipment.

- Q: I have a specific design I'd like to cut out of thin sheet metal (aluminum or tin) and I'm wondering how to make it more sturdy. The sheet metal is a bit flimsy. Can I strengthen it by heating it up (butane torch) and cooling it quickly?

- No. In fact, aluminum (and I believe tin) work harden when hammered - as do brass and copper and you heat to anneal and then you can cool fast or slow, still soft. Tin has a very low melting point and hitting it with a torch, especially if thin, will probably put a hole in it. The chances of you actually having tin sheet metal are very low - tin cans are zinc plated steel or some other coating. Steel does harden when quench, but heating tin or zinc coated metal is likely to damage the coating and perhaps give off noxious fumes - especially zinc.

- Q: Are aluminum sheets suitable for soundproofing applications?

- Aluminum sheets are not typically suitable for soundproofing applications as they have low mass and do not effectively block or absorb sound waves.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: What does 3003-O aluminum mean?

- There are four basic states of aluminum alloys:F--Free the condition of a product after a normal working procedure requires no special heat treatment or hardening, and the mechanical properties are not limited.

- Q: This question asks for a comparison of the cost of aluminum sheets with other building materials.

- <p>Aluminum sheets are generally considered cost-effective compared to other building materials, especially when considering their long-term benefits. They are relatively inexpensive to produce and install, and their low maintenance requirements can save costs over time. However, their initial cost may be higher than some materials like wood or vinyl. Aluminum's resistance to corrosion and weathering means it lasts longer, which can offset the higher upfront cost. In contrast, materials like steel might be more expensive due to their weight and the cost of corrosion protection, while concrete and masonry are typically more costly for both materials and labor. The cost-effectiveness of aluminum can vary based on regional prices, specific project requirements, and the type of aluminum product (e.g., thickness, finish).</p>

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Adhesive Backed Aluminum Foil Sheets - Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords