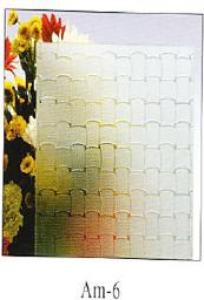

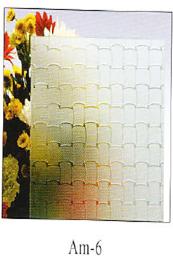

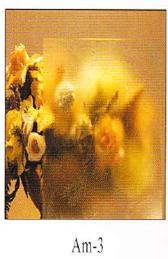

Acid Etching Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Acid Etching Glass, which is fingerprint-proof, can be etched either a single side or both sides.

Features:

A wide range of colors and patterns:

Specifications:

Thickness: 2-12mm

Size:

3300*2440mm

300*300mm

customized size

Applications:

Acid Etching Glass is mainly used for indoor decorations like doors, windows, screens, partitions, furniture, handrails, enclosures, fences, etc.

- Q: How is glass made? What are the main ingredients?

- Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) are crushed to damp the raw materials, and the iron bearing raw material is treated with iron to ensure the quality of the glass.

- Q: Is the production of glass materials as thin as possible? Why?

- Superfine powder in water, stirring, mixing will form a group, how big a mass is equivalent to how much a grain of sand, that is not melting, and eventually in the glass liquid to leave stones, become impurities.

- Q: Toughened glass and ordinary glass, process and raw materials what is the difference, a little more detailed, thank you

- Toughened glass is the re processed product of ordinary glass.The main components in the glass is silicon dioxide, calcium oxide and sodium oxide, so called silicate glass. There are two ways to make glass toughened. They are physical tempered (air cooled steel) and chemical steel.Tempered glass adopts a chemical tempering method. The principle is the sodium ion with the "head" the larger potassium ions replace the glass surface "head" is small, so that the glass surface is a state, which is the formation of compressive stress, so that the glass has very high impact resistance (increased by about 5 times).

- Q: Comparison of plexiglass steel bridge and inorganic glass steel bridge

- 4, can release harmful gases, human health and environmental protection have a certain impact. 5, high cost, but also a larger fluctuation of raw material prices. 6, after the waste is not easy to handle. Two, inorganic glass fiber reinforced plastics (referred to as Magnesium Oxide) advantages: 1, high temperature. (under normal circumstances, Fahrenheit temperature of 400 degrees Celsius, to maintain the product is not deformed), 2, anti-aging, 20 years without deformation of the product. 3. Purify the air and absorb carbon dioxide from the air. 4, high strength. 5, waterproof performance is good. 6, light weight, only in plexiglass.

- Q: What kind of glass is smoked glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- The production of glass bottles industry, its raw materials are stone powder, quartz sand, soda ash, waste glass and coalA variety of materials used in the preparation of glass batch, collectively referred to as glass raw materials. In general by the 7-12 component, the main material is 4-6, such as quartz sand, limestone, feldspar, sodium carbonate, boric acid, lead compounds, barium compounds, according to the introduction of oxides in the glass structure effect, can be divided into glass forming oxide materials, intermediate oxide materials, network oxides materials, according to the the properties of oxide, can be divided into raw material, acid alkali metal oxide oxide materials. The glass batch is obtained some necessary properties and accelerate the melting process of raw materials, although less, but it is very important that these materials as clarifying agent, fluxing agent, coloring agent, bleaching agent, emulsifying agent, oxidizing agent and reducing agent etc..The same raw materials, different formulations, the same raw materials, different habitats and different indicators, will affect product quality and production costs. In the case of a small gap in raw material costs, the glass bottles produced are very different from each other in the comparison of small samples, and the difference can only be seen in batch production.

- Q: Could you tell me that three yuan ethylene propylene (EPDM) rubber can resist ethylene glycol?

- Three yuan ethylene propylene rubber is ethylene, propylene and non conjugated diene three yuan copolymer, began commercial production in 1963. The consumption of the whole world is 800 thousand tons every year. The most important feature of EPDM is its superior oxidation resistance, ozone resistance and corrosion resistance. Because three yuan ethylene propylene rubber belongs to polyolefin family, it has excellent curing property. Of all rubbers, EPDM has the lowest specific gravity. It absorbs large amounts of fillers and oils and has little effect on properties. Therefore, rubber compounds with low cost can be made.

- Q: What raw materials are used for glass fiber reinforced plastics? Where can I buy them?

- 1, mold silicone rubber: glass fiber reinforced plastic products first need to use the mold silica gel to turn the mold, with the mold can be filled in the mold into other materials. To buy mold silica gel, it is best to directly look for manufacturers, but also to have their own brand trademark of the mold silicone manufacturers, quality and after-sale protection, you can Baidu.2 resin: FRP resin is divided into epoxy resin and unsaturated resin, epoxy resin used less, generally used for high-grade requirements of relatively high glass fiber reinforced plastic products. So we usually use unsaturated resin, and unsaturated resin is divided into #191, #196, #168 several models, #191 quality times, #168 is better unsaturated resin. We can choose different models according to their own requirements. General glass fiber reinforced plastic stores are on sale.

- Q: How do I see whether the raw material of tempered glass is made of float glass or standard glass?!

- Float glass surface flat, good brightness, no tumor and bubble (less).The surface of the lattice is not very smooth, and the ripples can be seen from the side. Uneven thickness

- Q: What are the production processes and raw materials of float glass?

- The qualified mixture is then sent to a glass furnace, and in the range of temperature, a uniform glass solution is obtained by melting, clarification, homogenizing and cooling. The glass liquid through the flow passage and launder into the tin bath filled with protective gas of nitrogen and hydrogen, floating on the surface of molten tin, complete glass liquid natural tree, thin, flat show polishing, after cooling, with glass transition roller table hold left into the annealing annealing and tin bath. The annealed glass band can be taken as a product after cutting, checking and packing.

We are a scientific enterprise engaged in the design, research, manufacturing, development and sale of art glass (decorative glass).

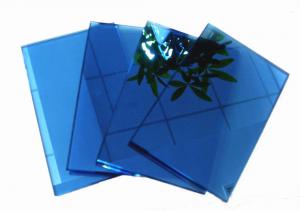

Our main products are acid etched glass, frosted glass, no fingerprint glass, deep acid etched glass, acid etched color mirror, silk screening glass, paint coated glass, color mirror etc.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe; Southern Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-9000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao, Dalian |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Acid Etching Glass-4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords