Acid Etching Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

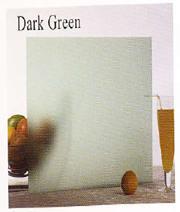

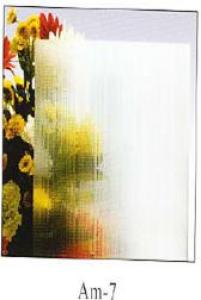

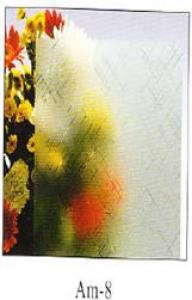

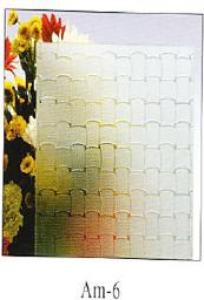

Acid Etching Glass, which is fingerprint-proof, can be etched either a single side or both sides.

Features:

A wide range of colors and patterns:

Specifications:

Thickness: 2-12mm

Size:

3300*2440mm

300*300mm

customized size

Applications:

Acid Etching Glass is mainly used for indoor decorations like doors, windows, screens, partitions, furniture, handrails, enclosures, fences, etc.

- Q: What kind of raw materials should be used in making FRP?

- The raw material of glass fiber reinforced plastic is divided into two kinds: reinforced material and base materialThe reinforced material of glass fiber reinforced plastic is composed of glass fiber and its fabric. It is the main load-bearing component material of glass fiber reinforced plastics, and has a direct impact on the strength and stiffness of FRP

- Q: The main chemical constituents of ordinary glass

- In the process of making glass, if you add some metal oxides, can also be made of colored glass. For example, adding Co2O3 (cobalt oxide) after the glass is blue, after joining the Cu2O glass is red. We see the ordinary glass, generally pale green, this is because the raw material is mixed with two valent iron for the sake of.There are many kinds of glass. Besides the ordinary glass introduced above, there are some other kinds of glass, such as quartz glass, optical glass, and so on

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- According to the degree of finish is divided into yaguangyoumianzhuan and light glazed tiles. At present, the ground material with more matte glazed tiles.The tiles (or tiles) is the use of earth embryo (or earth embryo to add some ore powder) after high temperature and high pressure one-time firing, using the surface and bottom of embryo material basically identical (except for the special process such as tiles, tiles in the new fill glaze series). Vitreous tile belongs to all ceramic product. Its abrasion resistance and flexural strength are very high, the water absorption rate (tile water absorption rate is less than 1 per thousand). Before the tiles mainly used for flooring, tiles, as a wall material is mainly used for high-grade Gaestgiveriet Hotel, office space, but now, with the living standard and the improvement of consumption level, the home use tiles for the kitchen wall materials are more and more family.

- Q: What is the difference between white float glass and ordinary float glass?

- The iron oxide content of ultra white float glass is low, so the raw materials (sand or sandstone) to low iron content, iron content can be the best sand control below 0.03%

- Q: Can the toughened glass be cracked by the sun?

- Tempered glass (Tempered, glass/Reinforced, glass) belongs to safety glass. Toughened glass is a kind of prestressed glass, in order to improve the strength of the glass, the methods commonly used in chemistry or physics, formed on the surface of glass glass under compressive stress, first offset surface stress force, so as to improve the bearing capacity of reinforced glass, its wind, cold, impact etc.

- Q: Is glass steel pipe used for re examination?

- The main construction phase: a layer structure (scheme, technical disclosure basis has been included, steel raw materials, testing report report, flash butt welding, electroslag welding sampling, sample, steel concealed, reinforcing steel bar, batch inspection, template technology review).

- Q: What material does PCB have?

- There are many kinds of copper clad laminates. According to different material can be divided into paper substrate, glass cloth substrate and synthetic fiber board; according to the different binder resin is divided into phenolic, epoxy, polyester and polytetrafluoroethylene; use can be divided into general and special type.

- Q: What is the difference between FRP and carbon fiber?

- Glass fiber (formerly known as English: glass fiber or fiberglass) is a kind of excellent inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance. It is a glass ball or waste glass as raw materials by high temperature melting, wire drawing, winding and weaving process for production, the filament diameter of several microns to twenty micron, the equivalent of a hair 1/20-1/5, each bundle of fibers by hundreds or even thousands of root root filaments. Glass fiber is usually used as reinforcing material in composite materials, electrical insulation materials and insulation materials, circuit boards and other fields of national economy.

- Q: What kind of glass material is used in the aquarium?

- Ordinary glassEmerald green, fragile, transparency is not high, rain, exposure, aging, deformation, and do not amount to the production of fish tanks.

- Q: What are the production processes and raw materials of float glass?

- Float glass production process refers to the glass liquid in molten metal floating on the surface of the flat glass production process. The production process of float glass is to select the raw material needed for the production of glass according to the designed glass composition, and weigh various raw materials according to the designed material, and then prepare the mixture by mixing.

We are a scientific enterprise engaged in the design, research, manufacturing, development and sale of art glass (decorative glass).

Our main products are acid etched glass, frosted glass, no fingerprint glass, deep acid etched glass, acid etched color mirror, silk screening glass, paint coated glass, color mirror etc.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 100 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe; Southern Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-9000;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao, Dalian |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Acid Etching Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords