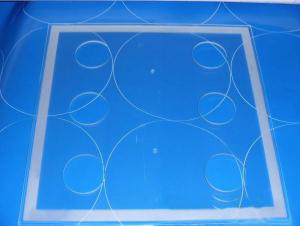

Silkscreen Printing Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Silkscreen Printing Glass is a kind of glass on which inorganic enamel is printed by silkscreen printing machines. After being printed on, it will be dried and heated under high temperature to make the enamel adhere to the glass lastingly.

- Q: How is glass made? What are the main ingredients?

- Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) are crushed to damp the raw materials, and the iron bearing raw material is treated with iron to ensure the quality of the glass.

- Q: What's the name of the transparent plastic board in the market?

- Acrylic is a transliteration word, English is ACRYLIC. It is a chemical material. Chemistry called "PMMA" is a polyacrylate, commonly known as "after the special treatment of plexiglass", in the application industry, acrylic raw materials in general in the form of particles, plates, pipes and other forms.

- Q: Method for cutting thick glass

- Some glass processing before processing, to the original piece of glass polishing, cutting, edge grinding, drilling, washing and drying process, such as tempered glass, laminated glass etc.; there are some glass processing technology, processing after washing and drying, and then according to the use requirements of cutting, grinding, grinding and polishing drilling and washing as final products, such as glass mirror; in addition to the art glass, such as painting, printmaking, relief, need specific processing technology, these are for cold working glass. The cold processing of glass is to process glass products into the required process by means of a series of processing methods at normal temperature.

- Q: What are the paper made of? What is the glass made of? What is the plastic made of?

- Plastic polymer polymer synthesis {(polymer)}, also known as polymer or giant molecule (macromolecules), is generally known as plastic resin (plastics) or (resin), free to change form style. It is a kind of material which is synthesized by condensation or condensation of monomer material. It is composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and so on. Its main component is synthetic resin.

- Q: What are the raw materials made of glass and plastics?

- Polyethylene (Polyethylene, PE), referred to as PE. is ethylene organic polymer compound. Polyethylene is the best material in contact with food. Non-toxic, tasteless and odorless, conform to the hygiene standards of food packaging. Polyethylene film, transparent, with moisture, oxygen, anti acid and alkali resistance, air tightness in general, excellent heat sealing properties. Known as "plastic flowers" reputation. Plastic packaging and printing volume is the largest and most important materials.PVC-- PVC

- Q: How is glass made? What is its raw material?

- Glass is classified into flat glass and deep-processing glass. Flat glass is mainly divided into three kinds: that is, lead glass, two kinds of flat glass (slot / no groove), flat glass and float glass. The float glass is becoming the mainstream of glass manufacture because of its uniform thickness, flat top and bottom surface, high labor productivity and favorable management. And special glass is a large variety

- Q: Can ordinary white glass (Bai Jiuping) replace quartz glass?

- Quartz glass has a series of excellent physical and chemical properties, such as: 1, high temperature resistance. The softening point temperature of quartz glass is about 1730 DEG C, which can be used for a long time at 1100 DEG C, and the maximum temperature can reach 1450 DEG C for a short time. 2, corrosion resistance. Except hydrofluoric acid, quartz glass and other acids almost no chemical reaction, the acid resistance is 30 times 150 times of ceramic, stainless steel, especially the chemical stability at high temperatures, any other engineering materials are incomparable. 3. Good thermal stability. The quartz glass thermal expansion coefficient is extremely small, can withstand the temperature changes, the quartz glass is heated to 1100 degrees Celsius, the water will not burst into the room. 4, good light transmission performance. The quartz glass has better transmittance in the whole spectral range from ultraviolet to infrared, and the transmittance of visible light is above 93%. Especially in the ultraviolet spectrum region, the maximum transmittance is above 80%. 5 、 good electrical insulation performance. The resistance of quartz glass is equal to ten thousand times of that of ordinary glass. It is an excellent insulating material. It has good electrical properties even at high temperature.

- Q: Who can tell me the raw material and function of the flashy glass?

- Float and other molding methods, its advantages are: suitable for efficient manufacturing quality of flat glass, such as no wave, uniform thickness, smooth surface, upper and lower are parallel to each other; the scale of the production line is not affected by the forming method, energy consumption per unit of product is low; the finished high utilization rate; easy to scientific management and implementation across the board mechanization, automation, high labor productivity; continuous operation cycle of up to several years, is conducive to stable production; to provide suitable conditions for the on-line production of some new varieties, such as electric float reflective glass, annealing, cold end spraying film glass surface treatment etc..

- Q: The younger brother wants to know how the octagonal bead is produced Do you use one side of the machine to grind it? What kind of material is usually used in China? Is the price fixed according to the material used?

- Generally use K5 more.Grade a crystal beads: flat emery abrasive disc cutting, flat polishing disc polishing one by one, and thus high gloss. Glittering and translucent!

- Q: What's the connection between tempered glass and float glass?

- Tempered glass is made of ordinary glass in the tempering furnace

Established in 1996,we are a specialized manufacturer of float glass, reflective glass, laminated glass and tempered glass. We have become one of the most important manufacturers of glass in North China.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1996 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 101 - 200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 60,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Silkscreen Printing Glass-1

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords