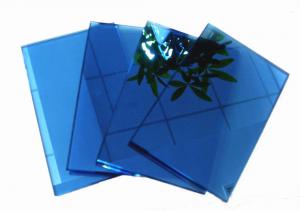

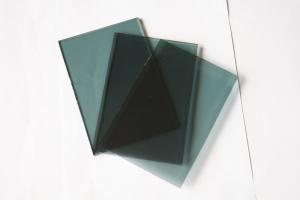

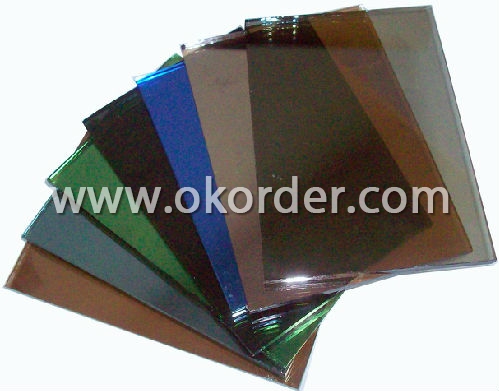

Colored Heat Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

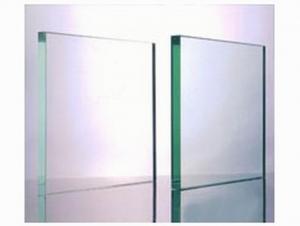

Heat-Reflective Coating Glass, also called Solar Control Coating Glass, is a kind of coated glass which has a specific coating deposited by online CVD (Chemical Vapor Deposition) or offline PVD (Physical Vapor Deposition), making the optical performances of the glass change and producing the required reflective color.

Features of Colored Heat Reflective Coated Glass:

1. Effectively limit the incident amount/incidence of the solar radiation with obvious shading effect.

2. Have a good view-obscured function for indoor objects and building components.

3. Save energy and reduce the running expenses of air conditioners.

4. Have a good decorative effect for the external walls of buildings.

5. Have a fine view-shielding function for indoor objects and construction components.

6. Designed for single use or composite use into coated laminated glass, coated tempered glass, coated insulating glass or other coated composite glass.

Specifications of Colored Heat Reflective Coated Glass:

Thickness: 3mm;4mm;5mm;5.5mm;6mm;8mm;10mm;12mm;15mm;19mm

Color: Dark Grey,Euro Grey,Ford Blue,Dark Blue,Ocean Blue,Pink, Clear,Dark Green, French Green,Bronze,etc.

Size:

2440*3660mm

2400*3300mm

2100*3300

customized size

Applications of Colored Heat Reflective Coated Glass:

Heat-Reflective Coating Glass is mainly used for curtain walls.

- Q: How do you make the glass, please? What is the raw material?

- When you look for information, the proportion of raw materials is very important.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Curtain walls shall be tested for raw materials and field inspection shall be carried out at the construction site. Including pullout test, water resistance test, etc., in details, you just need to read the data form

- Q: What's the raw material for goldfish bowl?

- Look + trend: ordinary glass, ultra white glass, float glass, acrylicApplication: ceramic containers

- Q: Not man-made destruction, why toughened glass suddenly broken?

- There are a variety of predisposing factors 2. tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q: How can the vacuum tubes of solar water heaters be chromatic aberration? Is purple good or sky blue good?

- Features: three, the absorption ratio of executives increased by 12%, the emission ratio decreased by 30% - 40%, super absorption, less heat loss, warming faster. Efficient tube, super absorption, high thermal efficiency, fast heating, in the same light condition, tube can be more than ordinary high temperature hot water; cold tube, due to launch Bibi aluminum ion copper ion is 0.2 lower, so the heat loss is small, can still work normally in the alpine environment, 30 degrees as often out of hot water; high temperature tubes, stainless steel for ion film high temperature resistant, anti air drying coating under the condition of 400 DEG C, aging, decay and discoloration.

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: What material does PCB have?

- The main material of printed circuit board (PCB) is copper clad laminate, and copper clad laminate is made up of base plate, copper foil and adhesive. The base plate is an insulating plywood made of macromolecule synthetic resin and reinforcing material;

- Q: What material is used in the protective film in the middle of glass?

- The raw material glass membrane used in general is Japan's Asahi pin and domestic luoyang,

- Q: What is the glass industry?

- The glass belongs to the chemical industry, glass production process mainly includes: raw material processed. The massive raw materials (quartz sand, soda ash, limestone, feldspar) grinding, wet material drying, iron containing raw materials for iron removal treatment, in order to ensure the quality of glass batch preparation. 2. The melting of glass batch. High temperature in the furnace or crucible kiln (1550~1600) heating, so as to form uniform, no bubbles, and meet the requirements of molding liquid glass.

- Q: What are the production processes and raw materials of float glass?

- Float glass production process refers to the glass liquid in molten metal floating on the surface of the flat glass production process. The production process of float glass is to select the raw material needed for the production of glass according to the designed glass composition, and weigh various raw materials according to the designed material, and then prepare the mixture by mixing.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Asia; Oceania; Mid East; Eastern Europe; North America; South America; Africa; |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 80% |

| No.of Employees in Trade Department | Above 1000 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Colored Heat Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords