Hot-bent Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

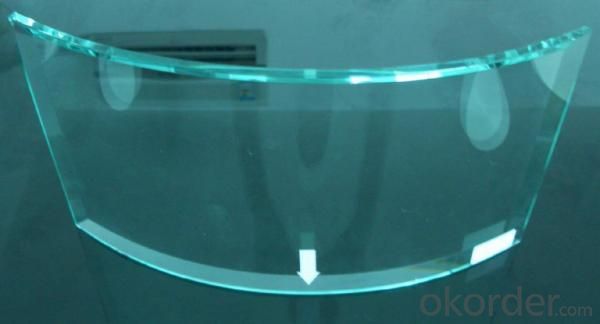

Hot-bent Glass, also called Curved Glass, is the important model for indoor and outdoor decorations. It is usually tempered for safety.

Features:

1、The accurate arc and smooth curve can satisfy the designers’ requirements for the streamline contour of the building to the greatest extent.

2、Unique shaping technology: flexible rollers are used for glass shaping with automatic accomplishment of corners bigger than 85°.

Specifications:

Thickness: 6-19mm

Size:

2400*2440mm(arc)

300*600mm(arc)

5000*2440mm(arc)

3200*3660mm(arc)

Min. Radius: 450mm

1500mm(for super large)

Min. Corner Radius: 100mm

Min. Corner: 85°

Applications:

Hot-bent Glass is widely used in the fields of shower room, luxurious furniture and architecture.

- Q: What kind of material is glass made of?

- We know that solid materials can be divided into two categories: organic materials and inorganic materials. Organic materials are wood, plastic, plexiglass, cotton, wool, nylon and so on. Inorganic materials can be divided into three categories: single crystal, polycrystal and glass according to the structure. A single crystal has regular shapes and strict rules, such as the ruby is an alumina single crystal, the crystal is a silica single crystal, and the diamond is a single crystal of carbon. Polycrystal is a collection of large amounts of small single crystals, and all kinds of ceramics and metals are polycrystalline materials. Glass is a noncrystalline solid obtained by melting, cooling, and curing. Its structure has certain rules (short-range order) in the atomic and molecular range, but there is no rule (long-range disorder) in the macroscopic range. It can be made into various shapes by moulds.

- Q: Twilight wall hollow glass with glass Zha glue with what is best?

- Groove type aluminum single channel seal, because of its poor sealing, easy to enter moisture, resulting in condensation of glass, frosting, short service life, so that the hollow {TodayHot} glass gradually eliminated.

- Q: The main chemical constituents of ordinary glass

- In the process of making glass, if you add some metal oxides, can also be made of colored glass. For example, adding Co2O3 (cobalt oxide) after the glass is blue, after joining the Cu2O glass is red. We see the ordinary glass, generally pale green, this is because the raw material is mixed with two valent iron for the sake of.There are many kinds of glass. Besides the ordinary glass introduced above, there are some other kinds of glass, such as quartz glass, optical glass, and so on

- Q: How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: What material is the automobile glass made of?

- General automotive glass by silicon glass, the main components of silica content more than 70%, the rest by sodium oxide, calcium oxide, magnesium and other components, made by the float process.. The glass is then further processed into tempered glass (TSG) or laminated glass (LSG).

- Q: Are there any materials that need to be tested in curtain work?

- Main profiles (including aluminum and steel profiles), screws, bolts, drawing test, four test, hardware fittings, etc.

- Q: Who can tell me the raw material and function of the flashy glass?

- Float and other molding methods, its advantages are: suitable for efficient manufacturing quality of flat glass, such as no wave, uniform thickness, smooth surface, upper and lower are parallel to each other; the scale of the production line is not affected by the forming method, energy consumption per unit of product is low; the finished high utilization rate; easy to scientific management and implementation across the board mechanization, automation, high labor productivity; continuous operation cycle of up to several years, is conducive to stable production; to provide suitable conditions for the on-line production of some new varieties, such as electric float reflective glass, annealing, cold end spraying film glass surface treatment etc..

- Q: Does the material of sunglasses choose good glass or plastic?

- Now, the most common use of sunglasses is resin lenses. The resin is a phenolic structure of chemicals, characterized by its light, high temperature resistance, impact resistance, and the ability to effectively block ultraviolet light. It should be said that this is a more excellent sunglasses, lens materials, polarized lenses made of this material will see more clearly.

- Q: Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

- Q: What's the difference between heat resistant glass and tempered / reinforced glass?

- Connaught licensing high borosilicate heat-resistant glassware with the new formulation, new technology, new technology, high strength, high temperature resistance, impact resistance, temperature change, not self advantages. With acid and alkali resistance, water resistance, high hardness, wear-resistant, easy to clean, should not knot stains, including harmful substances, and many other advantages, more close to the people's lives. The product is crystal clear, beautiful and practical. It is suitable for microwave oven, oven, refrigerator and so on. It can be cleaned by dishwasher through the 120 - meter shock resistance test. Can barbecue in microwave oven, absorb microwave very few, save energy, save electricity.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1997 |

| Annual Output Value | |

| Main Markets | Southeast Asia; Mid-East; Africa |

| Company Certifications | CE;RoHS;ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-bent Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords