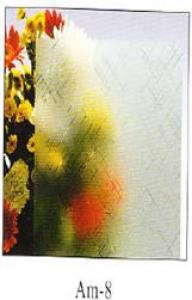

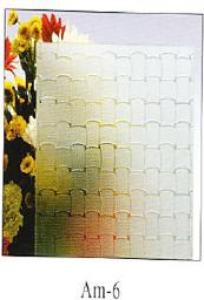

Acid Etching Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Acid Etching Glass, which is fingerprint-proof, can be etched either a single side or both sides.

Features:

A wide range of colors and patterns:

Specifications:

Thickness: 2-12mm

Size:

3300*2440mm

300*300mm

customized size

Applications:

Acid Etching Glass is mainly used for indoor decorations like doors, windows, screens, partitions, furniture, handrails, enclosures, fences, etc.

- Q: Is toughened glass dish loaded with food harmful to human body?

- The main chemical composition of glass products is silicon dioxide, sodium oxide, calcium oxide and other inorganic compounds, the precipitates of tableware national limit has strict rules, regular production of glass tableware, kitchenware is not harmful to humans, so consumers do not have to worry about the basic glass tableware utensils will cause harm to food safety. Daily exposure of glass tableware from the material can be divided into sodium, calcium, glass, that is, ordinary glass, borosilicate glass, lead crystal glass, glass ceramics.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Spray glaze workshop generally volatile material is relatively small, so, as long as a good protection, do not spray out of the glaze and lungs can be. Ceramic factory occupational disease is mainly pneumoconiosis, but now most of the ceramic dust prevention in this area is much better than before.

- Q: What material is the simulation tree made of?

- Usually according to different kinds of trees, there are many kinds of trees. Such as banyan cement, glass steel, really, there is fresh coconut tree trunk type is a reference material preservation, as we & apos. Therefore, the simulation tree generally does not specify a certain material.

- Q: How is glass made?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.

- Q: How is glass made? What is its raw material?

- Glass is classified into flat glass and deep-processing glass. Flat glass is mainly divided into three kinds: that is, lead glass, two kinds of flat glass (slot / no groove), flat glass and float glass. The float glass is becoming the mainstream of glass manufacture because of its uniform thickness, flat top and bottom surface, high labor productivity and favorable management. And special glass is a large variety

- Q: What is inorganic glass?Want to be a fish tank, where can I find inorganic glass?

- Comparison of properties between organic glass fiber reinforced plastic and inorganic glass fiber reinforced plastic,Organic glass fiber reinforced plastic (short resin) advantages: 1, good toughness; 2, high strength; 3, waterproof performance is good; 4, light weight (the same size of inorganic glass weight is about 1.2 times of plexiglass)Organic glass steel defects: 1, not high temperature. (in general, Fahrenheit 70 degrees Celsius, has started 2, not aging deformation). (ultraviolet effect of easy deformation and easy to fade) 3 burning.4, give off harmful gases to human health and environmental protection, the influence of.5, the cost is high, and the price of raw materials, the fluctuations of.6 waste is not easy to deal with.

- Q: Can ordinary white glass (Bai Jiuping) replace quartz glass?

- The glass is the main component in the manufacturing process of quartz sand, quartz sand is combined with other chemical materials at high temperature (1300 degrees Celsius) crystallized after firing the cooling of the body, with a hard, abrasion resistance, corrosion resistance and high transmittance characteristics, its wide application has a long history. The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: Are there any materials that need to be tested in curtain work?

- Main profiles (including aluminum and steel profiles), screws, bolts, drawing test, four test, hardware fittings, etc.

- Q: How is glass made? What material is it made of?.

- Bullet proof glass is made of glued laminated material, which is glued together with many pieces of glass or high strength organic board. Generally has the following three layers of structure:Bearing layer: firstly, the layer is broken by impact, and the glass with large thickness and high strength is used. It can destroy warhead or change warhead shape, and make it lose the ability to move forward.Transition layer: the general use of organic adhesive material, strong adhesion, light fastness, can absorb part of impact energy, change the direction of the bullet forward. A very strong and transparent chemical film is sandwiched between laminated glass. This can not only effectively prevent bullet shooting, but also has the properties of surge resistance, explosion resistance, shock resistance and no cracks after impact.Safety protection layer: this layer is made of high strength glass or high strength transparent organic material. It has better elasticity and toughness, can absorb most impact energy, and ensure that the bullet can not penetrate the layer

- Q: What are these things that belong to the reactor's raw materials?

- The oil immersed reactor is also wound with aluminum (copper) wire, and the insulation is insulated paper and then soaked in oil.

Our main product is glass, such as tempered glass, furniture glass, building glass, silkscreen printed glass, painted glass, sandblasted or acid etched glass, and more. Our products are widely used for architecture, electronics, and furniture, such as table tops, coffee tables, LCD TV bases, refrigeratory or air-condition front panels, exchange rate indicators, horologe panels, induction cooker panels, cabinets, shower glass doors, and other furniture.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1989 |

| Annual Output Value | US$ 1.0-1.5 Billion |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Acid Etching Glass-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords