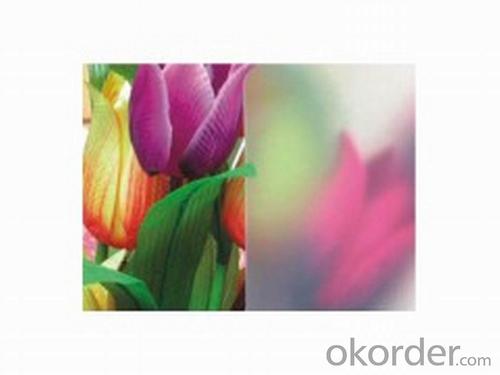

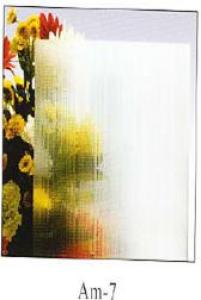

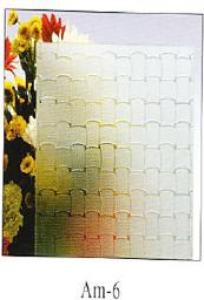

Clear Acid Etched Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acid Etching Glass, which is fingerprint-proof, can be etched either a single side or both sides.

Features of Clear Acid Etched Glass:

A wide range of colors and patterns.

Specifications of Clear Acid Etched Glass:

Thickness: 2-12mm

Size:

Max Size: 3300*2440mm

Min Size: 300*300mm

customized size

Applications of Clear Acid Etched Glass:

Acid Etching Glass is mainly used for indoor decorations like doors, windows, screens, partitions, furniture, handrails, enclosures, fences, etc.

- Q: Ask the glass making processWhat kind of material is the glass made of? What material is good?

- Glass: a liquid material is transparent, forming a continuous network structure in the melt, silicate nonmetalmaterials cooling process viscosity increases gradually and hardening without crystallization. The main ingredient is silica. Widely used in building, but to every wind light.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: Civil construction projects, exterior wall glass curtain wall raw materials, or construction process, or the end of the construction, what tests should be done?

- Do material testing (including stone moisture content, strength, steel and aluminum, chemical anchor pullout test, compatibility test of sealant, epoxy resin structural adhesive test), four test (water tightness, air tightness, wind pressure, plane deformation etc.)

- Q: Method for cutting thick glass

- Some glass processing before processing, to the original piece of glass polishing, cutting, edge grinding, drilling, washing and drying process, such as tempered glass, laminated glass etc.; there are some glass processing technology, processing after washing and drying, and then according to the use requirements of cutting, grinding, grinding and polishing drilling and washing as final products, such as glass mirror; in addition to the art glass, such as painting, printmaking, relief, need specific processing technology, these are for cold working glass. The cold processing of glass is to process glass products into the required process by means of a series of processing methods at normal temperature.

- Q: The benefits of natural thin wood planks

- Sheet material means a flat rectangular building material plate with a width of more than 2 times its thickness, usually made of flat rectangular building material, used as a wall, ceiling, or floor member. Also refers to the forging, rolling or casting of the metal plate, divided into thin plate, medium plate, thick plate, thick plate, usually made of standard size flat rectangular building material board.

- Q: What are the paper made of? What is the glass made of? What is the plastic made of?

- Plastic polymer polymer synthesis {(polymer)}, also known as polymer or giant molecule (macromolecules), is generally known as plastic resin (plastics) or (resin), free to change form style. It is a kind of material which is synthesized by condensation or condensation of monomer material. It is composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and so on. Its main component is synthetic resin.

- Q: What are the raw materials for producing edible glass bottles (such as pickles bottles, fermented beancurd bottles, etc.), and glass is the kind of glass material?

- In the production of glass products, raw materials are divided into general white material, high white material, super white material, and white material, the quality is getting better, he directly affects the glass transparency and crispness, better raw materials produced better quality glass products.

- Q: How is glass made? What material is it made of?.

- Bulletproof glass is the most important indicator of bullet proof ability. The target of bullet proof ability is measured from two aspects. On the one hand, it is the ability of security protection; on the other hand, it is the kill ability of the protective guns.

- Q: FRP process piping manufacturing process?

- Glass tube wall structure from inside to outside are: glass fiber reinforced plastic lining layer, glass fiber reinforced plastic sub lining layer, glass fiber reinforced plastic winding layer, glass fiber reinforced plastic external protection layer.

- Q: What kind of raw material does glass form? What is the general smelting process?

- It is a kind of quartz sand ore like ore, of course, a variety of quartz ore

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1989 |

| Annual Output Value | US$ 1.0-1.5 Billion |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Clear Acid Etched Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords