Cheap 48 X 96 AA8XXX Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA8xxx Aluminum Sheets Used for Construction Description

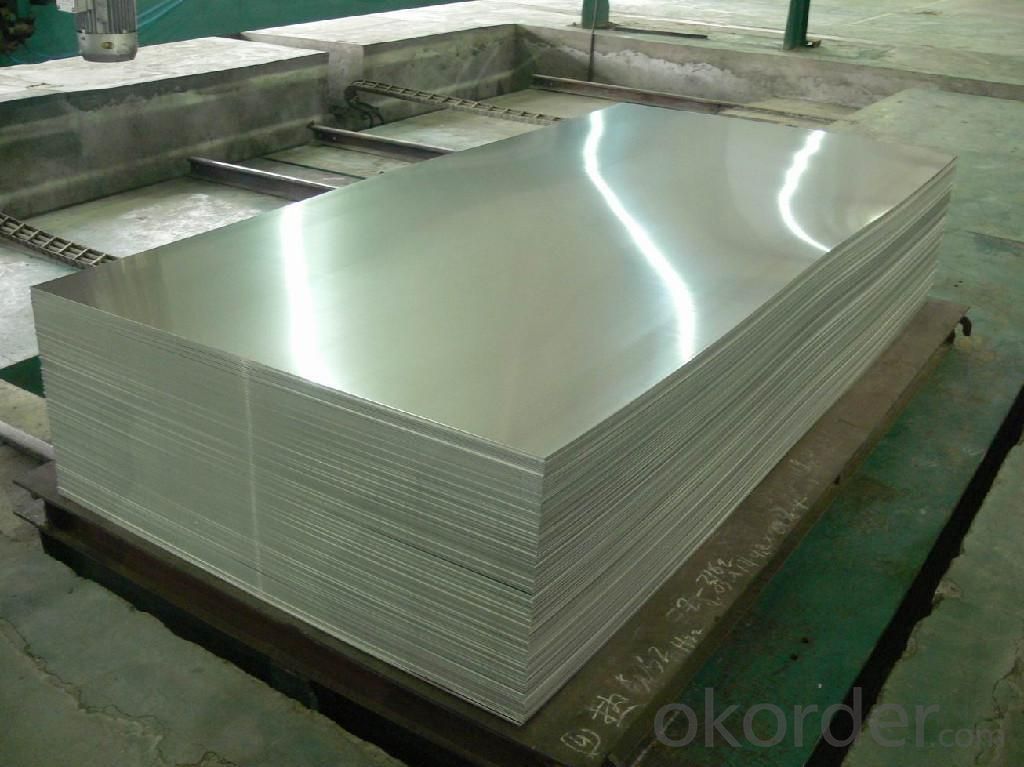

AA8xxx Aluminum Sheets Used for Construction is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA8xxx is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2.Main Features of AA8xxx Aluminum Sheets Used for Construction

1)excellent quality,good credit

2)competitive price,comfortable service

3)Samples for free

4)fast delivery,small order accepted

5)Good rust resistance

6)clean, flat, no wrinkle, no scratch, oil free.

3.AA8xxx Aluminum Sheets Used for Construction Images

4.AA8xxx Aluminum Sheets Used for Construction Specification

Alloy | AA8xxx |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA8xxx Aluminum Sheets Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum sheets suitable for use in automotive or aerospace industries?

- Aluminum sheets are indeed appropriate for utilization in both the automotive and aerospace sectors. Aluminum, being a lightweight yet robust material, is perfect for applications necessitating weight reduction, particularly in the aerospace domain where fuel efficiency holds paramount importance. Moreover, aluminum possesses commendable corrosion resistance qualities, a crucial attribute for both industries due to their exposure to diverse environmental conditions. Additionally, the malleability of aluminum permits effortless fabrication and forming, rendering it adaptable for a plethora of automotive and aerospace components. Finally, when compared to alternative materials, aluminum proves to be a cost-effective option, hence its popularity in these particular industries.

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: Are aluminum sheets suitable for chemical storage applications?

- Yes, aluminum sheets are suitable for chemical storage applications. Aluminum is a corrosion-resistant material that can withstand exposure to various chemicals, making it a suitable choice for storing a wide range of chemicals safely.

- Q: Describe the steps involved in the production of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, raw materials, primarily bauxite, are mined and then processed to extract alumina (aluminum oxide). This alumina is then mixed with cryolite and fed into a reduction cell where it is subjected to a strong electric current, causing the aluminum to be reduced and extracted. The molten aluminum is then poured into molds to cool and solidify into ingots. These ingots are subsequently rolled into sheets in a hot or cold rolling process, where they are gradually reduced in thickness and width. The sheets are then annealed to improve their ductility and strength. Finally, they undergo various finishing processes such as cleaning, coating, or cutting to meet specific requirements before being packaged and shipped to customers.</p>

- Q: I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- aluminum engines are used to save weight and help increase horsepower, I don't think that making an engine from aluminum is a bad thing, the biggest problem is making sure you NEVER EVER OVERHEAT IT. They use steel sleeves in the piston bores and other critical high stress areas, but the biggest problem is once overheated its done, vaporized aluminum is actually very explosive too, Any Eldorado's still around from 84 now, I think has a good engine in it. another potential problem is spark plug removal and installation, using an anti seize is recommended. If you do find an Eldorado's now, someone may have installed a iron block in it anyway, because one thing aluminum motors are known for, is being very expensive.

- Q: How do you prevent oil or grease stains on aluminum sheets?

- To prevent oil or grease stains on aluminum sheets, there are a few measures you can take: 1. Clean the aluminum sheets regularly: Regularly cleaning the aluminum sheets will help remove any existing oil or grease stains and prevent them from accumulating. Use a mild detergent or a mixture of water and vinegar to clean the sheets. Avoid using abrasive cleaners or scrubbing pads as they may damage the surface. 2. Apply a protective coating: Applying a protective coating can act as a barrier between the aluminum surface and oil or grease. There are various coating options available, such as clear lacquer or anodizing. These coatings create a smooth and non-porous surface, making it harder for oil or grease to penetrate and stain the aluminum sheets. 3. Use a barrier material: If you frequently work with oil or grease near aluminum sheets, consider using a barrier material to prevent direct contact. This could include using a silicone mat or placing a layer of parchment paper or aluminum foil between the aluminum sheet and the oil or grease source. 4. Store aluminum sheets properly: Proper storage is essential to prevent oil or grease stains on aluminum sheets. Make sure to store them in a clean and dry environment, away from any potential sources of contamination. Keep the sheets covered or wrapped in a protective material to prevent dust, dirt, or oil from settling on the surface. 5. Handle aluminum sheets with clean hands: When handling aluminum sheets, ensure your hands are clean and free of oil or grease. Even small amounts of oil or grease on your hands can transfer onto the sheets and cause stains. If necessary, wear clean gloves or use clean tools when working with aluminum sheets to minimize the risk of stains. By implementing these preventive measures, you can significantly reduce the chances of oil or grease stains on your aluminum sheets, keeping them clean and in good condition.

- Q: Can the aluminum sheets be used in food or beverage processing industries?

- Indeed, the food and beverage processing industries can utilize aluminum sheets. This non-toxic material is extensively employed in this field owing to its exceptional characteristics. Aluminum sheets boast corrosion resistance, light weight, and commendable thermal conductivity. These attributes render them perfect for a multitude of applications in the food and beverage processing industries, including food packaging, cooking utensils, storage containers, and beverage cans. Furthermore, aluminum proves to be an environmentally friendly choice as it is recyclable, thus amplifying its appropriateness for deployment in these sectors.

- Q: 4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The price is calculated according to the price of aluminum ingot + processing fees (aluminum state), the specific price according to the size of the aluminum plate, zero shear and the whole board price also has the difference, Jiangsu Yi Heng Liu Guangxi Henan Mingtai aluminum has the.

- Q: Okay guys i need to rapir a crack on an aluminum pipe , would durafix do the job ?? If so where can i get this durafix ? at my local home depot ?

- I've only found these type products online or at flea markets. It works quite well after a little practice.

- Q: why does aluminum sheet not react with sulfuric acid nut react with hydrochloric acid?

- aluminum reacts with hydrochloric acid,generating aluminium chloride which can dissolve in water. but aluminum reacts with sulfuric acid, generating aluminum sulfate which can't dissolve in water and will generate aluminum sulfate, a layer of protective film, preventing aluminum from reacting with sulfuric acid, so there is no significant phenomena.

Send your message to us

Cheap 48 X 96 AA8XXX Aluminum Sheets for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords