Aluminum Sheets with Holes AA8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

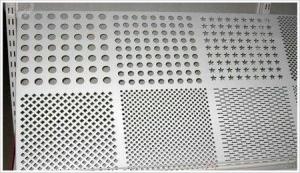

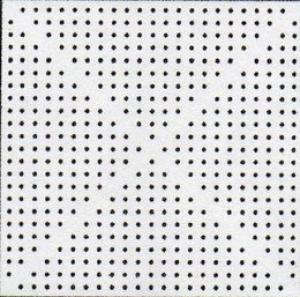

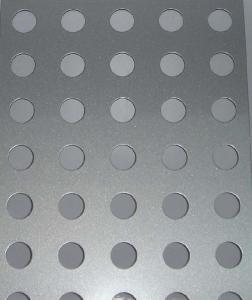

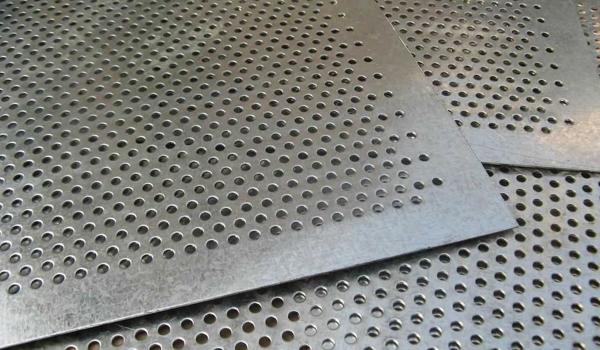

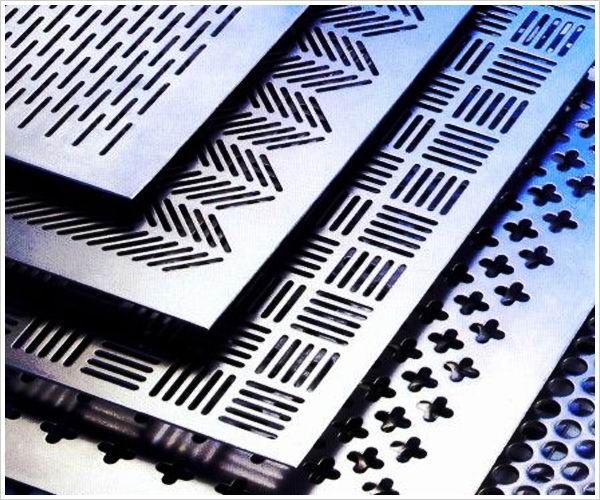

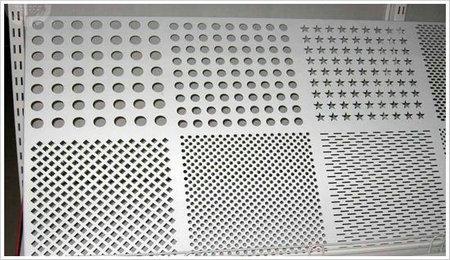

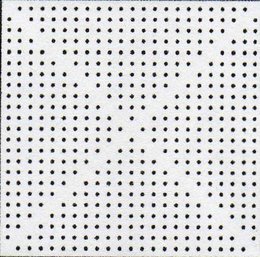

perforated aluminum sheets with holes

1.thickness:0.2-12mm

2.open area:10%-70%

3.width:0.5m-3m

4.shape:round,square,etc

The Characteristic of perforated aluminum sheets with holes:

Can be readily formed

Exact size

Can be painted or polished

Superior abrasion resisrance

Easy lnstculation

Attractive appearance

Wide range ofthickness available

Multl selecion ofhole size and forrn made

Uniform sound abafement

Light woight

Excellent wear life and durable

- Q: What should I pay attention to? What brand of aluminum plastic plate is good? Aluminum-plastic plate those manufacturers, please list, thank you!

- , Folding aluminum-plastic plate corner, easy to break is not PE material or doping to make false.

- Q: Reflective film mounted to the aluminum-plastic plate, just mounted on a very flat, a night arch on why

- Estimated quality problems

- Q: Aluminum slab plate and aluminum-plastic plate ceiling approach is not the same

- Practice is basically the same, the aluminum plate is the metal frame

- Q: Jiqiu material for the aluminum-plastic plate, due to years of wind and rain, dust deposition and other reasons, resulting in the appearance of rust, stains appearance rust method can clean? The

- Material for the aluminum-plastic plate, due to years of wind and rain, dust deposition and other reasons, resulting in rust, stains serious, the use of water rinse and oxalic acid dilution solvent cleaning no effect

- Q: Aluminum panels are used in what areas, can not be more detailed.

- The aluminum-plastic panels were first developed by the German company Aiusingen and later improved by Forken and Aloca. 90 years later, the product quality gradually stable, reached a high level. As the aluminum-plastic plate is composed of two different materials (metal and non-metallic), it retains the original composition of materials (metal aluminum, non-metallic polyethylene plastic) the main features, but also to overcome the lack of raw materials , And then get a lot of excellent material properties. Such as luxurious and beautiful, colorful decorative; weathering, corrosion resistance, impact resistance, fire, moisture, heat insulation, sound insulation, light resistance; light, easy processing, easy handling, quick construction and other characteristics. These properties for the aluminum-plastic plate opened up a broad application prospects.

- Q: I would like to ask where the fire aluminum plastic plate to sell ah?

- You can find Changzhou double European plate industry companies, fire rating can reach b1 level, product quality is good.

- Q: Imitation aluminum-plastic plate of the glass curtain wall, is a high-level curtain wall? What is the name and process?

- When the aluminum-plastic plate to imitate the glass, the choice of gloss and bright texture to imitation, so the current window of the future of aluminum-plastic manufacturers to introduce high-gloss aluminum-plastic plate is so born.

- Q: The minimum thickness of single-layer aluminum and aluminum-plastic composite panels for curtain walls

- Single-layer aluminum thickness of not less than 0.2mm

- Q: What is the difference between aluminum and aluminum curtain wall aluminum veneer? That cost is high!

- Composite aluminum plate for the upper and lower layers of high purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, also known as aluminum-plastic plate, aluminum veneer is a layer of aluminum. For the appearance of the difference between the two is not, but the color of aluminum-like pattern of some different. The price side of the curtain wall with the outer wall of aluminum-plastic board prices in 100 yuan, 2.5mm thick aluminum veneer prices around 240, 3mm veneer more expensive.

- Q: Seeking professionals to answer the ceiling gypsum board composite board solid wood board MDF aluminum panel panel What is the difference Thank you

- composite board: two or more materials synthetic board, solid wood composite, metal composite;

Send your message to us

Aluminum Sheets with Holes AA8xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords