Aluminum Decorative Sheets - AA5XXX Mill-Finished Aluminum Sheets for Construction in Las Vegas

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA5xxx Mill-Finished Aluminum Sheets Used for Construction Description

AA5xxx Mill-Finished Aluminum Sheets Used for Construction is cut from aluminum coils 5xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA5xxx Mill-Finished Aluminum Sheets Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA5xxx Mill-Finished Aluminum Sheets Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

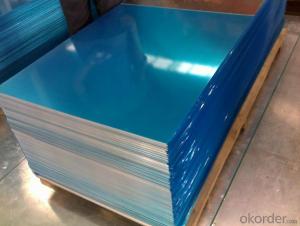

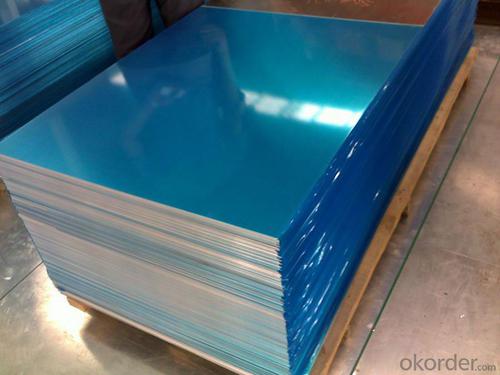

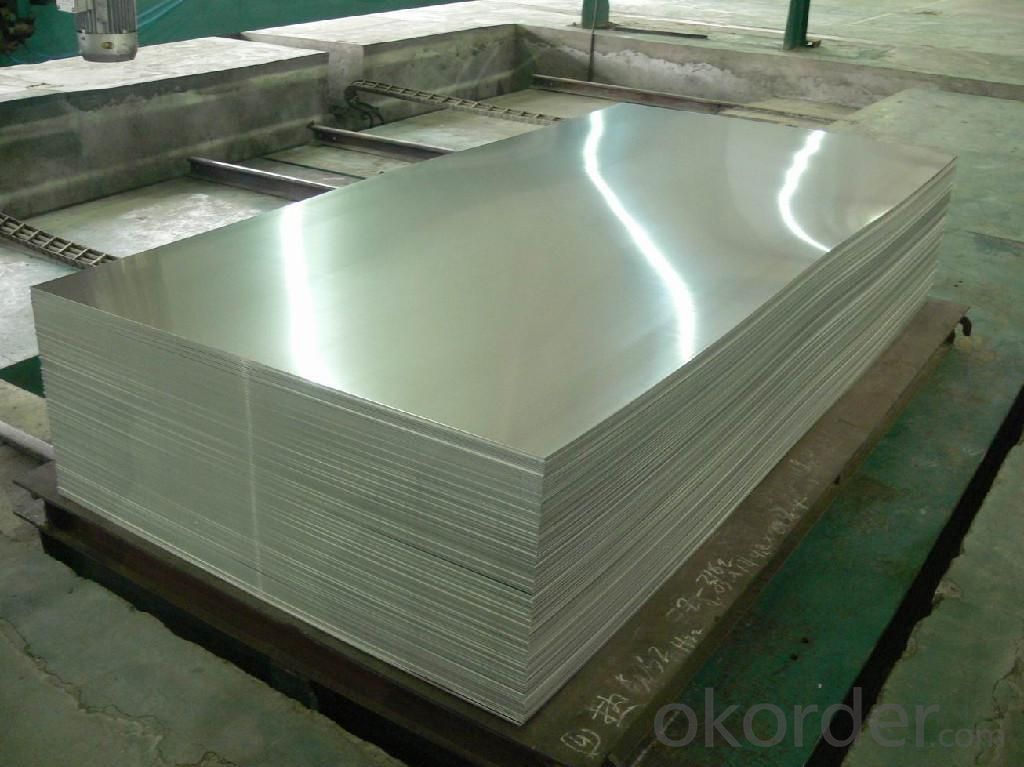

3.AA5xxx Mill-Finished Aluminum Sheets Used for Construction Images

4.AA5xxx Mill-Finished Aluminum Sheets Used for Construction Specification

Alloy | AA5xxx (AA5754,AA5083 etc) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA5xxx Mill-Finished Aluminum Sheets Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA5xxx Mill-Finished Aluminum Sheets Used for Construction.

B.When will you deliver the products?

AA5xxx Mill-Finished Aluminum Sheets Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: Can the aluminum sheets be used for manufacturing power transmission lines?

- Yes, aluminum sheets can be used for manufacturing power transmission lines. Aluminum has several properties that make it suitable for this purpose. First, aluminum is a lightweight material, which makes it easier to handle and transport compared to other metals like copper. This can help reduce installation costs and make the power transmission lines more efficient. Second, aluminum has good electrical conductivity, although it is not as conductive as copper. However, due to its lighter weight, aluminum can still achieve similar electrical performance as copper while using less material. This can result in cost savings and lower energy losses in the transmission lines. Furthermore, aluminum has excellent corrosion resistance, which is crucial for power transmission lines that are often exposed to various weather conditions and environmental factors. Aluminum can withstand harsh conditions and maintain its structural integrity over time, ensuring the reliability and longevity of the power transmission infrastructure. In conclusion, aluminum sheets can indeed be used for manufacturing power transmission lines due to their lightweight nature, good electrical conductivity, and excellent corrosion resistance.

- Q: why is aluminium used instead of copper for high voltage electrical cables????

- Aluminium provies much better conductivity to weight ratio meaning copper is ofcourse the better conductor but it is also a lot heavier than aluminum aluminium is 2.74g/cm? and copper is 8.64 g/cm? soo copper is three times as heavier and if you used that in cables it would be reallly messed up and dangerous and costly as you would need better material or infrastructure to hold the copper wire in air compared to aluminium which is easy to hold in air and is less dense and would be suitable for electrical cables

- Q: I need to know what composite bats do and how (or if) they are better than aluminum bats.

- one is made of aluminum and one isn't. haha i saw a movie and it had a guy and he said yo man i don't have your money

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly or sustainable buildings?

- <p>Yes, aluminum sheets can be used for green building projects. They are lightweight, strong, and durable, which reduces the amount of material needed and the energy consumed in transportation. Aluminum is also 100% recyclable, meaning it can be repurposed without losing quality, reducing waste and the need for new raw materials. Additionally, aluminum has a high reflectivity, which can help in reducing heat absorption and thus lowering cooling costs in buildings. These properties make aluminum a sustainable choice for green building initiatives.</p>

- Q: What kind of paint should be sprayed on the aluminium board?

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: What is the standard size of an aluminum sheet?

- The standard size of an aluminum sheet can vary depending on the specific application and industry. However, common standard sizes for aluminum sheets range from 4 feet by 8 feet (48 inches by 96 inches) to 5 feet by 10 feet (60 inches by 120 inches).

- Q: What are the different methods of surface protection for aluminum sheet?

- There are several different methods of surface protection for aluminum sheet that can be employed to enhance its durability and resistance to various external factors. One common method is anodizing, which involves creating a thick oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides corrosion resistance, improves wear resistance, and allows for color customization through the use of dyes. Another method is powder coating, where a dry powder is applied to the aluminum surface and then heated to create a durable and protective layer. Powder coating offers excellent resistance to chemicals, UV rays, and scratches, and it also provides a wide range of color options. Laminating is another technique used to protect aluminum sheets. In this method, a thin layer of protective film is applied to the surface, acting as a barrier against scratches, dirt, and moisture. Laminating is commonly used for aluminum sheets that require temporary protection during transportation or storage. Chemical conversion coating is yet another method employed to protect aluminum surfaces. This involves treating the aluminum with a chemical solution that creates a thin layer of protective coating. The coating not only enhances corrosion resistance but also improves paint adhesion. Furthermore, clear coating can be applied to aluminum sheets to provide a protective layer without altering the appearance of the metal. Clear coatings can be either solvent-based or water-based and offer resistance against corrosion, scratches, and UV rays. Lastly, mechanical finishes such as brushing or polishing can be used to protect aluminum surfaces. These finishes create a smooth and aesthetically pleasing surface while also providing some level of protection against corrosion and wear. Overall, these various methods of surface protection for aluminum sheet offer different levels of durability, corrosion resistance, and aesthetic options, depending on the specific requirements and applications.

- Q: Are aluminum sheets resistant to abrasion?

- Yes, aluminum sheets are generally resistant to abrasion due to their hardness and durability.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

Send your message to us

Aluminum Decorative Sheets - AA5XXX Mill-Finished Aluminum Sheets for Construction in Las Vegas

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords