Standard Aluminum Sheets - AA3XXX Hot Rolled Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA3xxx Hot Rolled Aluminum Coils Used for Construction Description

AA3xxx Hot Rolled Aluminum Coils Used for Construction is cut from aluminum coils 3xxx. AA3xxx Hot Rolled Aluminum Coils Used for Construction is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA3xxx Hot Rolled Aluminum Coils Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA3xxx Hot Rolled Aluminum Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

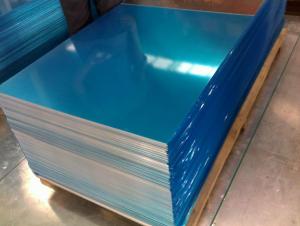

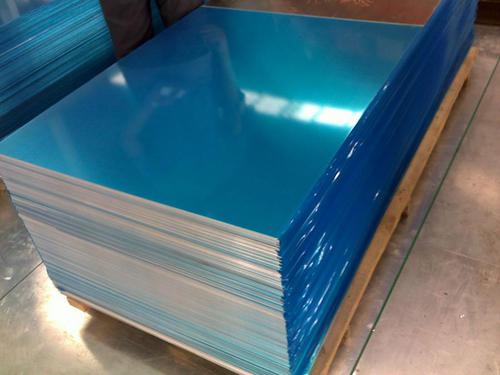

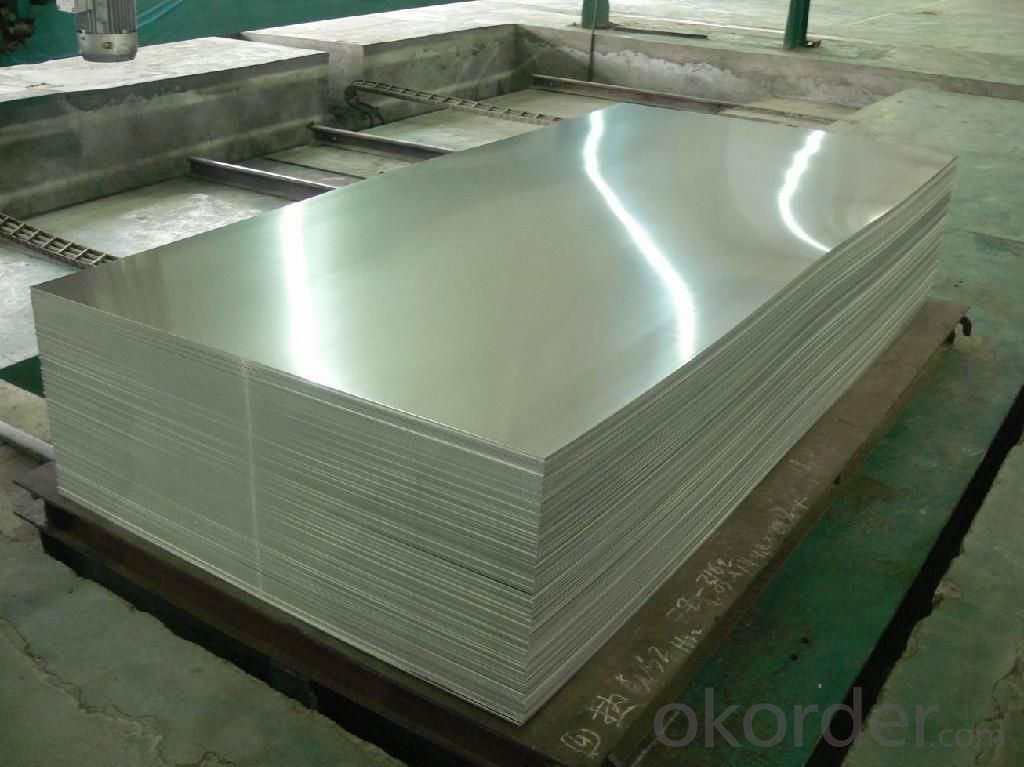

3.AA3xxx Hot Rolled Aluminum Coils Used for Construction Images

4.AA3xxx Hot Rolled Aluminum Coils Used for Construction Specification

Alloy | AA3xxx (AA3105 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Hot Rolled Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are the aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding.

- Q: What are the rules and standards that govern the use of aluminum sheets in construction projects?

- <p>Yes, there are regulations regarding the use of aluminum sheets in construction. These regulations vary by country and region but generally cover aspects such as material standards, safety, and environmental impact. For instance, in the United States, the American Society for Testing and Materials (ASTM) provides standards for aluminum sheet materials. Building codes like the International Building Code (IBC) also specify requirements for the use of aluminum in construction. These regulations ensure that aluminum sheets meet certain strength, durability, and performance criteria. Compliance with these regulations is crucial for safety, structural integrity, and to obtain necessary permits and approvals for construction projects.</p>

- Q: What are the different forms of aluminum sheet available?

- There are several different forms of aluminum sheet available on the market. These include: 1. Plain Aluminum Sheet: This is the most basic form of aluminum sheet, without any additional finishes or coatings. It is commonly used for general applications where appearance is not a major concern. 2. Painted Aluminum Sheet: This type of aluminum sheet is coated with a layer of paint or resin, which provides additional protection against corrosion and enhances the appearance of the sheet. It is often used for decorative purposes or in applications where aesthetics are important. 3. Anodized Aluminum Sheet: Anodizing is an electrochemical process that creates a durable and corrosion-resistant surface on the aluminum sheet. Anodized sheets have a uniform finish and are available in various colors. They are commonly used in architectural applications, such as building facades or interior design elements. 4. Perforated Aluminum Sheet: This type of aluminum sheet has small holes or perforations throughout its surface. It is often used in applications where ventilation, filtration, or aesthetics are important, such as in decorative screens, speaker grills, or air diffusers. 5. Embossed Aluminum Sheet: Embossing is a process that creates raised patterns or textures on the surface of the aluminum sheet. It adds visual interest and can also improve the sheet's strength and rigidity. Embossed aluminum sheets are commonly used in architectural or decorative applications. 6. Clad Aluminum Sheet: Cladding involves bonding a layer of aluminum to another material, such as stainless steel or copper, to combine their properties. Clad aluminum sheets are used in applications where the benefits of both materials are required, such as in the construction of heat exchangers or cookware. These are just a few examples of the different forms of aluminum sheet available. Each type offers unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, aerospace, and more.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are suitable for signage. They are lightweight, durable, and weather-resistant, making them a popular choice for outdoor and indoor signage applications. Additionally, aluminum sheets can be easily customized, printed, and mounted, allowing for versatile and long-lasting signage solutions.

- Q: is aluminum foil spacer poisonous after heating?

- It’s a kind of thermoprint material made by pressing the aluminum into sheet, and owing to its similar thermoprint effect to silver foil, so it’s called fake silver foil. Aluminum has soft texture, good ductility, and is silver white, if we use sodium silicate to paste the sheet after pressing on the offset paper, making aluminum foil, the foil can be printed. But aluminum foil is easy to be oxidized and darkens, rubbing and touching will make it darken, so it doesn’t suit for the thermoprint of books’ cover that needs to be preserved for a long time.

- Q: Can aluminum sheet be used for automotive body-in-white applications?

- Yes, aluminum sheet can be used for automotive body-in-white applications. Aluminum is lightweight, yet strong and durable, making it an ideal material for automotive applications. It offers a high strength-to-weight ratio, which helps improve fuel efficiency and overall vehicle performance. Additionally, aluminum's corrosion resistance properties make it suitable for withstanding harsh environmental conditions. Its formability allows for complex and intricate designs, enabling manufacturers to create lightweight yet rigid automotive structures. The use of aluminum in automotive body-in-white applications has become increasingly popular in recent years, as it helps reduce vehicle weight and emissions while maximizing safety and performance.

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: What is the thickness range of aluminum sheets?

- The thickness range of aluminum sheets can vary depending on the specific application and industry standards. However, commonly available aluminum sheets typically range in thickness from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). For more specialized applications, thicker aluminum sheets may be available. It is important to note that different alloys and grades of aluminum may have different thickness ranges, so it is essential to consult the specific requirements and standards of the intended use case.

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding purposes. Aluminum is a popular choice for cladding due to its numerous advantages. Firstly, it is lightweight, making it easier to handle and install. This reduces the overall weight of the cladding system and minimizes structural load. Secondly, aluminum is highly durable and resistant to corrosion, making it suitable for both interior and exterior applications. It is also weather-resistant, ensuring that the cladding remains in good condition even in harsh climates. Additionally, aluminum is a highly versatile material that can be easily shaped and fabricated, allowing for a variety of design options. It can be painted or coated with various finishes to enhance its appearance and provide additional protection. Moreover, aluminum cladding is low maintenance, as it does not require frequent cleaning or painting. Overall, aluminum sheets are an excellent choice for cladding due to their lightweight, durability, versatility, and low maintenance requirements.

- Q: What are the different types of surface treatments available for aluminum sheets?

- There are several different types of surface treatments available for aluminum sheets, each serving a specific purpose and providing unique characteristics. Some of the most common surface treatments for aluminum sheets include anodizing, painting, powder coating, and polishing. Anodizing is a process that involves the formation of a thick oxide layer on the surface of the aluminum sheet. This treatment not only enhances the appearance of the sheet by providing a variety of colors, but also improves its corrosion resistance and durability. Anodized aluminum sheets are widely used in architectural applications, automotive parts, and electronics. Painting is another popular surface treatment for aluminum sheets. It involves applying a layer of paint on the surface to enhance its appearance and provide additional protection against corrosion and wear. Painted aluminum sheets are commonly used in signage, building facades, and decorative applications. Powder coating is a type of surface treatment that involves applying a dry powder to the aluminum sheet and then heating it to create a protective layer. This treatment offers excellent durability, resistance to weathering, and a wide range of color options. Powder coated aluminum sheets are commonly used in the construction industry, as well as for automotive parts and appliances. Polishing is a surface treatment that involves buffing the aluminum sheet to create a smooth and reflective surface. This treatment enhances the aesthetics of the sheet, making it ideal for decorative applications such as furniture, jewelry, and architectural accents. Overall, the choice of surface treatment for aluminum sheets depends on the desired appearance, functionality, and application requirements. Each treatment offers unique benefits and characteristics, allowing for versatility and customization in various industries.

Send your message to us

Standard Aluminum Sheets - AA3XXX Hot Rolled Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords