AAxxx Hot Rolled Aluminum Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AAxxx Hot Rolled Aluminum Coils Used for Construction Description

AAxxx Hot Rolled Aluminum Coils Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AAxxx Hot Rolled Aluminum Coils Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AAxxx Hot Rolled Aluminum Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

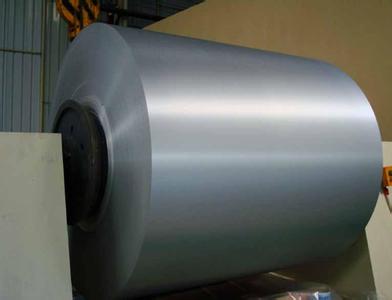

3.AAxxx Hot Rolled Aluminum Coils Used for Construction Images

4.AAxxx Hot Rolled Aluminum Coils Used for Construction Specification

Alloy | AA3xxx (AA3105 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AAxxx Hot Rolled Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I need help with 3 main ideas for a aluminum and copper chloride lab. I need evidence for these 3 ideas that what happened was a chemical reaction.

- Aluminum metal usually has a passivating layer of Al2O3 which prevents aluminum from reacting with Cu2+ ions. Al won't react with CuSO4(aq), for instance. But if NaCl is added then it will. It is the effect of the chloride ion that makes the reaction go. Al2O3(s) + 8Cl-(aq) + 3H2O -- 2[AlCl4]^- + 6OH- Once the passivating layer is dissolved, then aluminum metal is available to react with chloride ion. You see the aluminum metal disappear, while dark red Cu metal is formed, along with the decrease in the blue color due to hydrated copper ions, [Cu(H2O)6]^2+. In addition, aluminum metal has a side-reaction with water to form hydrogen gas. Therefore, you will observe that as gas is given off. Not only that, the temperature of the solution will increase. 2Al(s) + 2OH- + 6H2O -- 2[Al(OH)4]- + 3H2(g) In summary. There are four indicators of a chemical reaction. 1. The formation of a precipitate 2. The evolution of a gas 3. A color change 4. A temperature change. All four indicators are observed. Solid Cu metal is formed. Hydrogen gas is given off. The color of the solution changes from blue to colorless, and the temperature increases.

- Q: What are the different protective coatings available for aluminum coils?

- There are several different protective coatings available for aluminum coils. Some common options include: 1. Polyester Coating: This is a versatile coating that provides excellent weather resistance and color retention. It is commonly used in outdoor applications where the aluminum coils may be exposed to harsh weather conditions. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings are known for their exceptional durability and resistance to fading, chalking, and chemical exposure. They are often used in architectural applications where a long-lasting and high-performance finish is required. 3. Epoxy Coating: Epoxy coatings offer excellent adhesion and corrosion resistance. They are frequently used in industrial settings, such as in the manufacturing of appliances or automotive parts. 4. Acrylic Coating: Acrylic coatings provide good weatherability and UV resistance. They are commonly used in interior applications or in environments with mild outdoor exposure. 5. Polyurethane Coating: Polyurethane coatings offer a high level of impact resistance and flexibility. They are often used in applications where the aluminum coils may be subject to physical stress or deformation. 6. Ceramic Coating: Ceramic coatings provide superior heat resistance and thermal stability. They are commonly used in automotive applications or in environments with high-temperature exposure. Overall, the choice of protective coating for aluminum coils depends on the specific application requirements, such as weather resistance, durability, or chemical resistance. It is important to consider the environmental conditions and performance expectations when selecting the appropriate coating for aluminum coils.

- Q: Are there any limitations on the anodizing of aluminum coils?

- The anodizing of aluminum coils is subject to certain limitations. To begin with, the size and weight of the aluminum coils can present constraints. Anodizing is typically carried out in tanks or baths, so the coil must fit within the tank's capacity. Moreover, larger and heavier coils may necessitate specialized equipment or processes to ensure proper anodizing. Furthermore, the alloy composition of the aluminum coils can impact the anodizing process. Different aluminum alloys respond differently to anodizing, and some alloys may not anodize as effectively as others. It is crucial to consider the alloy composition and seek advice from experts to determine the suitability and potential limitations of anodizing specific aluminum coils. Additionally, the surface condition of the coils can influence the quality of anodizing. Imperfections such as scratches, dents, or surface contaminants can affect the consistency and uniformity of the anodized layer. It is vital to thoroughly clean and prepare the coils before anodizing to achieve the desired outcome. Lastly, certain design features or complex shapes of the aluminum coils can present challenges for anodizing. Anodizing involves immersing the coil in an electrolyte solution, and intricate designs or complex shapes may hinder the achievement of a uniform coating thickness. Overcoming these limitations may require specialized masking or racking techniques. Collaborating closely with anodizing experts or service providers is essential to comprehend and address any limitations specific to the aluminum coils, ultimately achieving the desired anodizing results.

- Q: Can aluminum coils be used for electrical transformers?

- Yes, aluminum coils can be used for electrical transformers.

- Q: Are aluminum coils applicable in the manufacturing process of automobiles?

- <p>Yes, aluminum coils are widely used in automobile manufacturing. They are utilized in various components such as engine parts, body panels, and wheels due to their lightweight, corrosion resistance, and strength. Aluminum's recyclability and energy efficiency also make it an environmentally friendly choice for the automotive industry.</p>

- Q: I have been reading up on thermite and the required ingredients. I have extremely fine aluminum powder from a small etch-a-sketch sitting on plastic wrap in my room. On the comments page of the site i got the thermite ingredients from, multiple people said that thermite could explose if you use too fine of a powder. I have also read that powdered aluminum can become very explosive when it is exposed to air or if it becomes damp. Ive gotten particulary worried because the humidity right now is 93%. So, is powdered aluminum too dangerous to have in house and is too fine powdered aluminum explosive when in thermite?

- It is now not aluminum powder; it's ALUM powder, which is one more chemical. Nonetheless, it would not fairly tighten your vagina, despite what some commercials will say. I've not heard of beydary capsules, but I also doubt that they might do anything to fix the predicament either. If a real vaginal shrinking capsule was once on hand, it would be recognized and really trendy, similar to viagra is. Your best wager is to do kegel exercises to fortify and tone your vaginal muscular tissues. These, and nothing else, can help make your vagina tighter.

- Q: Can a spring balance be used to accurately determine the weight of an aluminum coil?

- <p>Yes, you can use a spring balance to measure the weight of an aluminum coil, but the accuracy depends on the balance's specifications. Ensure the balance has a sufficient capacity to measure the coil's weight and is calibrated correctly. Keep in mind that spring balances are less precise than electronic scales, especially for heavy or sensitive measurements. For high accuracy, consider using an electronic scale designed for industrial use.</p>

- Q: Can aluminum coils be used in the production of aluminum cladding?

- Yes, aluminum coils can be used in the production of aluminum cladding.

- Q: Are aluminum coils resistant to moisture?

- Yes, aluminum coils are highly resistant to moisture. Aluminum has a natural oxide layer that forms on its surface, which acts as a protective barrier against moisture and prevents corrosion. This makes aluminum coils an excellent choice for applications where exposure to moisture is a concern, such as in HVAC systems or outdoor equipment.

- Q: Are aluminum coils suitable for aerospace applications?

- Yes, aluminum coils are suitable for aerospace applications. Aluminum is a widely used material in the aerospace industry due to its excellent properties such as lightweight, high strength-to-weight ratio, corrosion resistance, and good thermal conductivity. These properties make aluminum coils ideal for various aerospace applications, including aircraft structures, wings, fuselage, and engine components. Additionally, aluminum coils can be easily formed into different shapes and sizes, allowing for efficient manufacturing and customization. Overall, the use of aluminum coils in aerospace applications helps to improve fuel efficiency, reduce overall weight, and enhance performance and durability in challenging environments.

Send your message to us

AAxxx Hot Rolled Aluminum Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords