Aluminum Coil White AA3003 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA3003 Prepainted Aluminium Coils Used for Construction Description

AA3003 Prepainted Aluminium Coils Used for Constructionare widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

Direct Continuous Aluminium Foil Stock in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

2.Main Features of AA3003 Prepainted Aluminium Coils Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

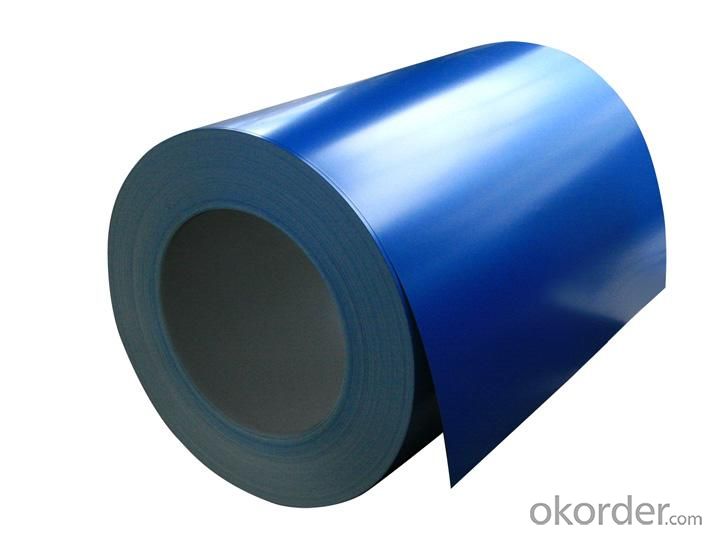

3.AA3003 Prepainted Aluminium Coils Used for Construction Images

4.AA3003 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA3003 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to utilize aluminum coils in the construction industry as building materials?

- <p>Yes, aluminum coils can be used for building materials. They are valued for their lightweight, corrosion resistance, and strength. Aluminum coils are commonly used in roofing, siding, window frames, and facades due to their durability and low maintenance requirements. Additionally, they can be easily shaped and recycled, making them an environmentally friendly option in construction.</p>

- Q: Are aluminum coils compatible with different welding methods?

- Yes, aluminum coils are compatible with different welding methods such as MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and even resistance spot welding. These methods can be used to join aluminum coils effectively and efficiently.

- Q: Is it possible to use aluminum coils for decorative purposes in a garden setting?

- <p>Yes, aluminum coils can be used for decoration in the garden. They are lightweight, durable, and resistant to corrosion, making them suitable for outdoor use. You can form them into various shapes or use them to create unique garden structures such as trellises, sculptures, or even as part of a fence. Their metallic finish can add a modern or industrial touch to your garden's aesthetic, and they can be painted or left in their natural state to blend with different garden themes.</p>

- Q: Can aluminum coils be painted?

- Indeed, it is possible to paint aluminum coils. By applying paint to aluminum coils, an extra layer of protection against corrosion can be achieved, along with an improvement in their aesthetic appearance. Nevertheless, it is crucial to properly prepare the surface prior to painting in order to ensure a strong adhesion and durability. This typically involves a thorough cleaning of the coils, the removal of any existing paint or coatings, and the application of a primer specifically designed for aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. For optimal and long-lasting results, it is advisable to use a high-quality paint specially formulated for metal surfaces. Additionally, following the instructions provided by the manufacturer and taking into account any environmental factors, such as temperature and humidity, that could impact the painting process, is of utmost importance.

- Q: Are aluminum coils suitable for corrosion-resistant applications?

- Yes, aluminum coils are suitable for corrosion-resistant applications. Aluminum has a natural oxide layer that forms on its surface, which provides excellent corrosion resistance. This oxide layer acts as a barrier, protecting the underlying aluminum from corrosion caused by moisture, chemicals, and other environmental factors. Additionally, aluminum can be further enhanced with various coatings or treatments to improve its corrosion resistance even more. Therefore, aluminum coils are commonly used in applications where resistance to corrosion is crucial, such as in the construction industry, automotive industry, and marine applications.

- Q: What is the maximum coil diameter for aluminum coils?

- The maximum coil diameter for aluminum coils can vary depending on the specific application and manufacturing process. However, in general, the maximum coil diameter for aluminum coils typically ranges from 60 inches (152.4 cm) to 120 inches (304.8 cm). This diameter limit is determined by factors such as the size of the production equipment, the thickness and width of the aluminum sheet being processed, and the handling capabilities of the facility. It is important to consult with the manufacturer or supplier to determine the specific maximum coil diameter for a particular aluminum coil product.

- Q: high-quality hi-fi power and amplifiers generate large amounts of heat. to dissipate the heat and prevent damage to the electronic components, heat-radiating metal fins are used. would it be better to make these fins out of iron or aluminum? specific heat capacities for aluminum and iron are 0.89 J/degrees C.g and 0.45 J/degrees C.g, respectively. explain your answer

- Aluminum, because it dissipates heat faster.

- Q: How do aluminum coils perform in saltwater environments?

- Aluminum coils perform exceptionally well in saltwater environments due to their natural resistance to corrosion. Unlike other metals, aluminum forms a protective oxide layer when exposed to saltwater, creating a barrier that prevents further corrosion. This oxide layer acts as a durable and long-lasting shield against the harsh effects of saltwater, ensuring the longevity and performance of aluminum coils in marine applications. Additionally, aluminum coils are lightweight and possess high thermal conductivity, making them popular choices for heat exchangers and condensers in saltwater-based cooling systems. Overall, aluminum coils are highly reliable and efficient in saltwater environments, making them a preferred choice for various marine applications.

- Q: What are the typical production volumes for aluminum coil manufacturers?

- The typical production volumes for aluminum coil manufacturers vary depending on the size and capabilities of the specific manufacturer. However, it is common for aluminum coil manufacturers to produce thousands to tens of thousands of tons of aluminum coils annually, catering to the demands of diverse industries such as construction, automotive, and packaging.

- Q: Are there any safety concerns when handling aluminum coils?

- Yes, there are some safety concerns when handling aluminum coils. One of the main concerns is the risk of injury from sharp edges. Aluminum coils are typically formed into long, thin sheets that can have sharp edges. It is important to handle them with care and wear appropriate protective gloves to avoid cuts and abrasions. Another safety concern is the potential for injury due to the weight of the coils. Aluminum coils can be quite heavy, especially when they are stacked together. It is important to use proper lifting techniques and equipment to prevent strains and back injuries. Additionally, there is a potential risk of fire when handling aluminum coils. Aluminum is a highly flammable material and can ignite if exposed to sparks, open flames, or high temperatures. It is crucial to store and handle aluminum coils away from any potential ignition sources and ensure that the area is well-ventilated to prevent the buildup of flammable vapors. Finally, it is important to be aware of the potential health risks associated with aluminum. While aluminum itself is not considered highly toxic, there is some evidence to suggest that prolonged exposure to high levels of aluminum can be harmful to human health. Therefore, it is important to take appropriate precautions, such as wearing respiratory protection when working with aluminum coils in dusty environments and following proper hygiene practices to minimize the risk of exposure. Overall, with proper training, precautions, and adherence to safety guidelines, the risks associated with handling aluminum coils can be minimized.

Send your message to us

Aluminum Coil White AA3003 Prepainted Aluminium Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords