Aluminum Coil Canada - AA1100 Prepainted Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

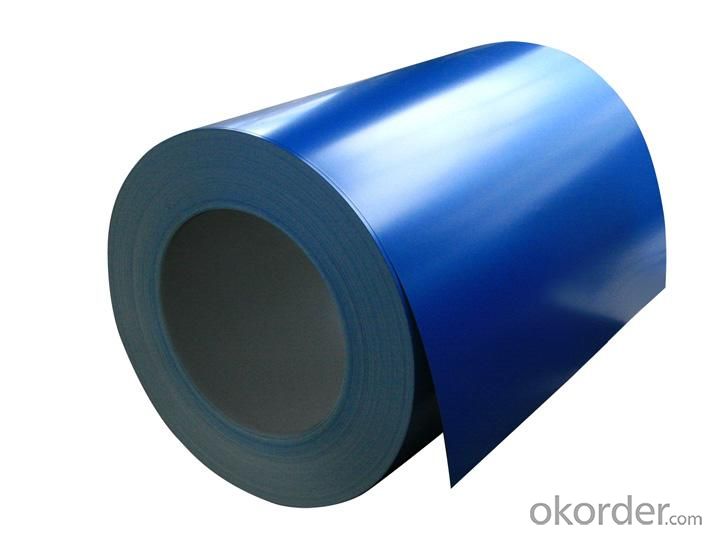

1.Structure of AA1100 Prepainted Aluminium Coils Used for Construction Description

AA1100 Prepainted Aluminium Coils Used for Construction are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

AA1100 Prepainted Aluminium Coils Used for Construction have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of AA1100 Prepainted Aluminium Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.AA1100 Prepainted Aluminium Coils Used for Construction Images

4.AA1100 Prepainted Aluminium Coils Used for Construction Specification

Alloy | AA1100 |

Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

Thickness | 0.03mm-3.0mm |

Width | 30mm-1700mm |

Coating | PE,PVDF,Epoxy |

Painting Thickness | Standard 16-25 Mic, max 40 Mic |

Color | According to RAL colors or customers' samples |

Standard | GB/T 17748-1999 |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2000mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Aluminum reacts with water so why is it used in buildings and cooking??Some help by today would be good!! :DThanxx

- Aluminum reacts with water under certain conditions, but cookware does not usually present any of those conditions. Aluminum cookware takes advantage of the oxidizing process, which creates a natural protective layer over the aluminum. It doesn't react with water in the same way that chemical equations say it will because cooking surfaces are designed to maximize the oxidation effect. This is basically the same reason why aluminum foil doesn't react in water. In building materials, it's less about exposure to the elements and more about how cheap and lightweight it is. Many building materials are aluminum alloys, which makes them more susceptible to corrosion than purer aluminum, and the use of aluminium roofing material, though fairly corrosion-resistant by itself (for the same reasons as cookware), gets compromised by the proximity of other metals used in construction, like non-stainless steel nails and screws, for example, or copper pipes without insulation. The trade-off is that aluminium alloys hold their shape better and have greater tensile strength, some of which approach that of steel.

- Q: Is it possible to utilize steel wires in the creation of jewelry or decorative items?

- <p>Yes, you can use steel wires for making jewelry or decorations. Steel wires are durable and can be shaped into various forms, making them suitable for a range of designs. They are often used in wire wrapping techniques and can be combined with beads or other materials. However, it's important to consider the type of steel used; stainless steel is more resistant to rust and is commonly preferred for jewelry making. Additionally, steel wires may require special tools for cutting and bending, and proper safety measures should be taken during the crafting process.</p>

- Q: What are the different coil slitting methods used for aluminum coils?

- There are several coil slitting methods used for aluminum coils, including rotary shear slitting, loop slitting, and simultaneous multi-blanking. These methods involve different techniques and equipment to precisely cut and separate aluminum coils into narrower strips or sheets. Each method has its advantages and is chosen based on factors like coil thickness, width, and desired output.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: Can aluminum coils be painted for custom designs?

- It is indeed possible to paint aluminum coils to achieve personalized designs. The act of painting the coils opens up a world of limitless options for customization and aesthetic appeal. Various colors, patterns, and designs can be applied to the coils, catering to individual tastes and needs. To complete the painting process, the surface must first be cleaned, followed by the application of a primer and the desired paint or coating. Through this method, one can create distinctive and captivating custom designs suitable for a wide array of purposes, including architectural elements, signage, automotive components, and more. Moreover, the paint not only safeguards the aluminum from corrosion but also enhances its durability.

- Q: Can aluminum coils be used in power generation facilities?

- Aluminum coils are indeed suitable for use in power generation facilities. Aluminum, being a highly conductive material, offers numerous benefits for power generation applications. Its exceptional thermal conductivity allows for efficient heat transfer from the coils, a critical factor in cooling systems within power generation facilities. Moreover, aluminum's lightweight nature simplifies handling and installation, setting it apart from metals such as copper. This lightweight attribute also contributes to cost savings by reducing overall equipment weight. Additionally, aluminum's corrosion resistance is particularly valuable in power generation facilities, which frequently operate in challenging environments. In conclusion, considering their conductivity, thermal efficiency, lightweight nature, and corrosion resistance, aluminum coils present a feasible choice for power generation facilities.

- Q: This question asks about the maintenance difficulty of aluminum coils.

- <p>Aluminum coils are relatively easy to maintain. They are resistant to corrosion and do not require frequent cleaning or special treatments. Regular inspection for any physical damage or signs of wear is sufficient. However, it's important to keep them dry and clean to prevent any potential issues. For specific applications, such as in HVAC systems, regular cleaning may be necessary to ensure optimal performance. Overall, maintenance is minimal compared to other materials.</p>

- Q: What is the melting point of aluminum coils?

- The melting point of aluminum coils is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: What is the typical density of aluminum coils?

- The density of aluminum coils can differ depending on the particular alloy and manufacturing method employed. Generally, aluminum coils have a density of approximately 2.7 g/cm³. This value is slightly lower than pure aluminum, which has a density of 2.7-2.8 g/cm³. It should be noted that the density of aluminum coils can also be affected by factors such as coil thickness and any surface coatings or treatments applied.

- Q: Is it possible to utilize an aluminum coil for heating purposes?

- <p>Yes, aluminum coil can be used as a heater. Aluminum is a good conductor of heat, making it suitable for applications where heat transfer is necessary. However, it's important to note that aluminum has a lower melting point compared to other metals like copper or steel, so it's not ideal for high-temperature applications. Aluminum coils are commonly used in electric heaters, such as toasters and air heaters, where they can efficiently transfer heat to the surrounding air or materials. Always ensure that the aluminum coil is used within safe temperature limits to prevent damage or safety hazards.</p>

Send your message to us

Aluminum Coil Canada - AA1100 Prepainted Aluminum Coils for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords