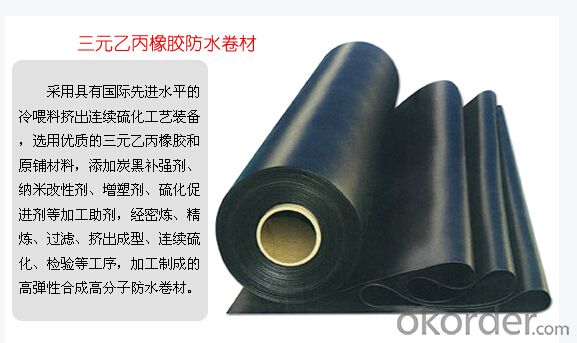

A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

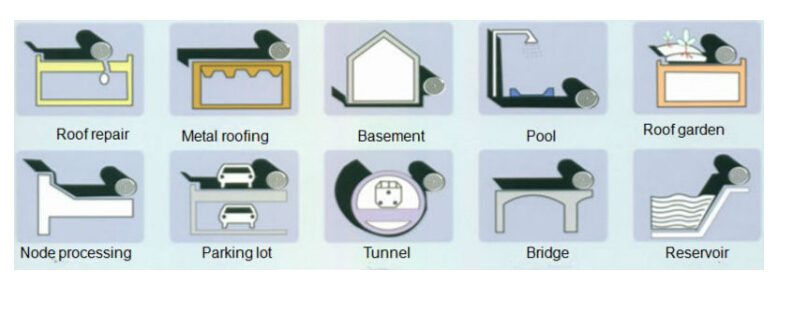

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

3. Product Application:

a. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

b. Reinforce the parts which are easy to leak, such as seam, hole, channel, wall, pipe and corner.

c. Application Method:

Lay the membrane directly. Be careful to control the overlaps of the long side and short side.

d. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

4. Some photos:

- Q: Can a waterproofing membrane be used in steam rooms?

- Yes, a waterproofing membrane can be used in steam rooms. A waterproofing membrane is designed to prevent water infiltration and is commonly used in areas where moisture is present, such as bathrooms, showers, and steam rooms. The membrane acts as a barrier, preventing water vapor from penetrating the underlying structure and causing damage. In steam rooms, where high levels of humidity and moisture are present, using a waterproofing membrane is essential to protect the walls, floors, and other surfaces from water damage and mold growth. It is important to choose a waterproofing membrane that is specifically designed for high moisture environments like steam rooms to ensure proper protection and longevity. Additionally, proper installation and adherence to manufacturer guidelines are crucial for the effectiveness and durability of the waterproofing membrane in a steam room setting.

- Q: Are waterproofing membranes suitable for tunnels?

- Yes, waterproofing membranes are suitable for tunnels. Tunnels are often subjected to high water pressure from the surrounding soil and groundwater, making them vulnerable to water ingress. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can effectively prevent water from entering the tunnel structure. These membranes are typically made of durable materials such as bitumen, PVC, or EPDM rubber, which are resistant to water penetration. They are applied to the tunnel walls and ceiling to create a continuous, impermeable layer that keeps the tunnel dry. The membranes are also flexible, allowing them to accommodate any movement or settlement of the tunnel without compromising their waterproofing integrity. In addition to preventing water infiltration, waterproofing membranes also offer other benefits for tunnels. They can protect the tunnel structure from corrosion caused by water and chemicals, prolonging its lifespan. They can also help to improve the indoor air quality within the tunnel by preventing the growth of mold and mildew, which thrive in damp environments. Furthermore, waterproofing membranes can be customized to suit different tunnel conditions. For example, in tunnels that are exposed to high levels of hydrostatic pressure, reinforced membranes with higher tensile strength can be used to withstand the added stress. Additionally, membranes with enhanced fire resistance properties can be utilized in tunnels where fire safety is a concern. Overall, waterproofing membranes are a reliable and effective solution for ensuring the durability, safety, and longevity of tunnels by providing a robust barrier against water ingress.

- Q: Can a waterproofing membrane be used in conjunction with paint or coatings?

- Yes, a waterproofing membrane can be used in conjunction with paint or coatings. In fact, combining a waterproofing membrane with paint or coatings is a common practice in many construction and renovation projects. The waterproofing membrane provides a barrier against moisture and prevents water infiltration, while the paint or coatings add aesthetic appeal and can provide additional protection against UV rays, weathering, and chemical exposure. By using both in conjunction, you can achieve a dual-layer protection system that ensures long-lasting durability and water resistance. However, it is essential to ensure compatibility between the waterproofing membrane and the paint or coatings to avoid any adverse reactions or loss of effectiveness. Consult with a professional or manufacturer guidelines to determine the best combination and application process for your specific project.

- Q: Are waterproofing membranes suitable for commercial applications?

- Indeed, waterproofing membranes prove to be a fitting choice for commercial applications. Specifically designed to safeguard buildings, structures, and surfaces from water infiltration, moisture damage, and similar issues, waterproofing membranes are frequently employed in diverse commercial scenarios such as roofs, basements, underground parking garages, and exterior walls. Commercial structures face a wide array of weather conditions and water sources, encompassing rainfall, snowfall, and groundwater. Waterproofing membranes serve as a dependable barrier, effectively preventing water penetration and averting costly water-related harm. Furthermore, they serve as a vapor barrier, mitigating moisture accumulation and condensation within the building envelope, which may otherwise lead to mold growth and structural decay. Waterproofing membranes are obtainable in various materials including bitumen, modified bitumen, EPDM, PVC, and TPO. Each material boasts distinct advantages and characteristics, allowing for flexibility in choosing the most appropriate option for specific commercial applications. They can be applied as liquid coatings, sheets, or panels, providing versatility in terms of installation methods to accommodate diverse building designs and requirements. Moreover, waterproofing membranes can be tailored to cater to specific commercial needs such as fire resistance, UV protection, and durability. This renders them highly effective in safeguarding commercial properties that may be subjected to heavy foot traffic, mechanical equipment, or other potential sources of damage. To summarize, waterproofing membranes prove to be an exceptionally suitable solution for commercial applications. They offer reliable protection against water infiltration, moisture damage, and related issues, ensuring the longevity and structural soundness of commercial buildings. Their versatility, customizable options, and ability to withstand various weather conditions make them an outstanding choice for commercial waterproofing requirements.

- Q: Can a waterproofing membrane be used for bridge abutments?

- Yes, a waterproofing membrane can be used for bridge abutments. Waterproofing membranes are commonly used in construction to prevent water infiltration and protect structures from moisture damage. Bridge abutments, as critical components of bridge infrastructure, can benefit from the installation of a waterproofing membrane to ensure long-term durability and structural integrity.

- Q: Can waterproofing membranes be used on plant rooms?

- Indeed, plant rooms can benefit from the utilization of waterproofing membranes. Within these rooms, one can typically find various apparatus and machinery that necessitate safeguarding against potential water harm. By implementing waterproofing membranes, a formidable defense is established to impede water infiltration, averting leaks and potential destruction to both the plant room and its contents. Typically, these membranes are administered to the walls, floors, and roofs of the plant room to ensure comprehensive waterproofing. Moreover, in addition to their water resistance, these membranes possess the ability to shield against other elements such as chemicals and fluctuations in temperature, rendering them an optimal solution for plant rooms.

- Q: Can waterproofing membranes be used on mechanical rooms?

- Yes, waterproofing membranes can be used on mechanical rooms. These membranes are designed to provide a protective barrier against water infiltration, making them suitable for use in areas prone to moisture or water exposure, such as mechanical rooms.

- Q: How to choose waterproof membrane

- Second, from the fetal base to identify the quality of the coil Generally from the product on the cross-section of visual inspection, the specific method can be purchased products by hand to tear it, observe the cross-section exposed fetal fiber, composite tires tear after the section of the grid cloth ribs exposed, this time It can be concluded that the product must be a composite tire coil, what kind of composite tire membrane with physical properties test - soluble content test to observe the exposed fetal base. And simple polyester tires, glass fiber tires after tearing the section only polyester or fiberglass fiber exposed.

- Q: Can a waterproofing membrane be applied in cold weather or during winter months?

- Yes, a waterproofing membrane can be applied in cold weather or during winter months. However, it is important to follow the manufacturer's guidelines and use products specifically designed for cold weather applications. Cold weather may affect the curing time of the membrane, so it is recommended to take necessary precautions and allow sufficient time for proper curing to ensure the effectiveness of the waterproofing.

- Q: Can a waterproofing membrane be used on storage tanks?

- Yes, a waterproofing membrane can be used on storage tanks. Waterproofing membranes are designed to create a barrier that prevents water or other liquids from penetrating through the surface they are applied to. When applied to storage tanks, these membranes can provide protection against leaks, corrosion, and damage caused by moisture. They are commonly used in various industries, including oil and gas, chemical, and water treatment, to ensure the integrity and longevity of storage tanks. Additionally, waterproofing membranes can be tailored to meet specific requirements, such as resistance to chemicals, UV exposure, or high temperatures, making them suitable for a wide range of storage tank applications.

Send your message to us

A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords