8x10 Sheets Aluminum Engraving - Alloy 5083 Flat Aluminum Sheet for Manufacturing Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy 5083 Flat Aluminum Sheet for Manufacturing Boat

l Product Introduction

Aluminium has a lot of salient properties that the other metals do not have. It is very strong, yet it is not very heavy. Like other metals, it conducts electricity and heat to a moderate degree. Most industries require aluminium sheets for various purposes. Aluminium can be easily beaten into sheets because of its high malleability. It has the preoperty of light weight, medium strength, easy-forming and anti-corrosion.

l Product Description

| Alloy 5083 Flat Aluminum Sheet for Manufacturing Boat | |||||

| Packing: wooden pallets that are suitable for long distance exporting | |||||

| Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

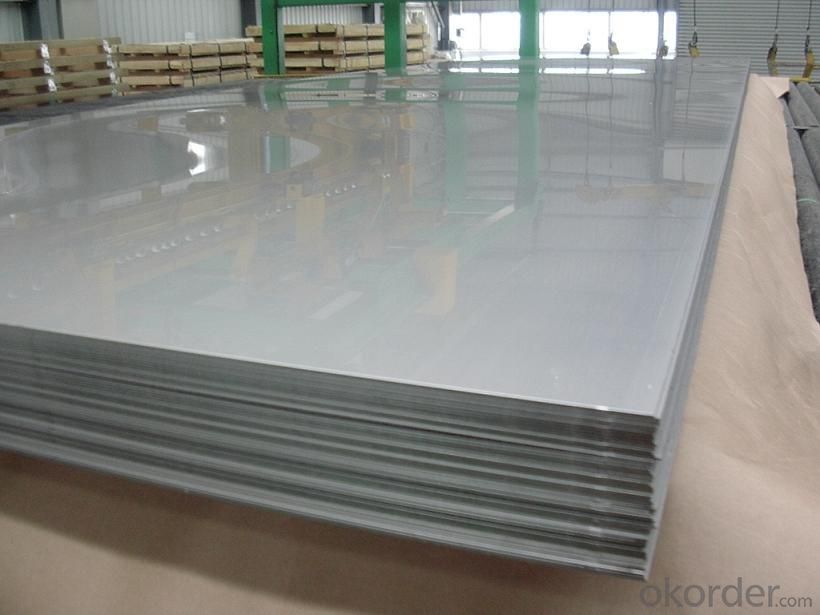

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

| Application: Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

| MOQ | 2.5 tons | ||||

| Payment term: | T/T,L/C | ||||

| Delivery Time | depend on the order q'ty | ||||

| Kind attention : Specifications can be customized as the customer’s requirements. | |||||

l Packaging & Delivery

Packaging detail: pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: within 30 days after we get your 30% deposit or L/C

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

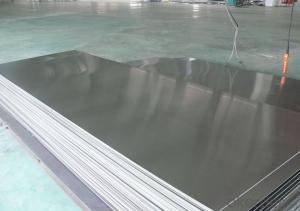

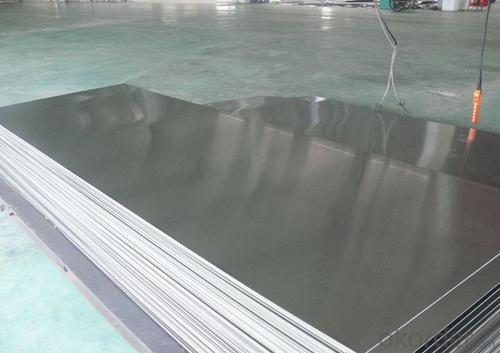

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What are the different alloys available for aluminum sheets?

- There are several different alloys available for aluminum sheets, each with its own unique properties and applications. Some of the most common alloys include: 1. 1100: This is a commercially pure aluminum alloy with excellent corrosion resistance, making it suitable for applications where high levels of corrosion resistance are required, such as in marine environments. 2. 3003: Another commercially pure alloy, 3003 offers good formability, high corrosion resistance, and moderate strength. It is commonly used for general sheet metal work, cooking utensils, and chemical equipment. 3. 5052: This alloy is known for its high fatigue strength and excellent corrosion resistance, particularly in saltwater environments. It is often used in marine applications, as well as for aircraft components and fuel tanks. 4. 6061: A heat-treatable alloy, 6061 exhibits good weldability and formability, along with high strength and excellent corrosion resistance. It is commonly used in structural components, such as frames and railings, as well as automotive parts. 5. 7075: This alloy is known for its high strength-to-weight ratio, making it ideal for aerospace applications and high-stress structural components. However, it is less corrosion resistant than other alloys and may require protective coatings in certain environments. These are just a few examples of the alloys available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable alloy for your specific needs.

- Q: Are aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant due to the formation of a protective oxide layer on their surface.

- Q: Are aluminum sheets suitable for roofing systems?

- Yes, aluminum sheets are suitable for roofing systems. They are lightweight, durable, corrosion-resistant, and can withstand harsh weather conditions. Additionally, aluminum sheets have a long lifespan, require minimal maintenance, and are eco-friendly, making them a popular choice for roofing in many applications.

- Q: Can aluminum sheet be used for insulation?

- Aluminum sheet can be used for insulation, but it is not as effective as other insulation materials, such as fiberglass or foam. Aluminum has a low thermal conductivity, meaning it is a poor conductor of heat. However, it does not have good insulating properties on its own because it does not provide much resistance to heat flow. In order to use aluminum sheet for insulation, it is commonly combined with other insulating materials to enhance its effectiveness. For example, aluminum foil is often used as a radiant barrier in buildings to reflect heat and reduce the amount of heat transferred through walls and roofs. Overall, while aluminum sheet can contribute to insulation, it is usually used in conjunction with other materials to provide better thermal insulation.

- Q: What are the different methods of surface embossing aluminum sheets?

- Aluminum sheets can be embossed using various techniques, each with its own distinct process and result. Some commonly employed methods are: 1. Mechanical Embossing: To create patterns or designs on the aluminum sheet, mechanical tools like rollers or presses are utilized. The sheet is either passed through the rollers or pressed against a surface with a pattern, which impresses the design onto the metal. Mechanical embossing is ideal for repetitive patterns like diamond or checkerplate designs. 2. Chemical Embossing: This technique involves etching or engraving the aluminum sheet using chemical solutions. The solution is selectively applied to the metal's surface, eating away the desired areas to leave an embossed pattern. Chemical embossing enables the creation of intricate and detailed designs on the aluminum sheet. 3. Heat Embossing: By applying heat, embossed designs are formed on the aluminum sheet. A heated die or stamp is pressed onto the metal's surface, causing it to deform and create the desired pattern. Heat embossing is commonly used for raised logos or text on aluminum sheets. 4. Laser Embossing: Laser technology is employed to achieve embossed designs on aluminum sheets. A laser beam is directed onto the metal's surface, vaporizing or melting the desired areas to form the embossed pattern. Laser embossing offers high precision and allows for intricate and complex designs. 5. Roll Embossing: In this method, the aluminum sheet is passed through a series of engraved rolls, which imprint the desired pattern onto the metal. Each roll has a distinct design, providing a range of embossed finishes. Roll embossing is often used for textured or decorative finishes on aluminum sheets. In conclusion, the various techniques for surface embossing aluminum sheets offer multiple options for creating visually appealing and unique designs. The choice of method depends on the desired outcome, complexity of the design, and specific project requirements.

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- Fiberglass Bass Boats

- Q: 3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- Attached: O status: fully annealed to obtain the lowest strength of the processing products. 8 state: hard working state (9)

- Q: Can 101 aluminum sheets be anodized in different colors?

- Yes, 101 aluminum sheets can be anodized in different colors.

- Q: How are aluminum sheets manufactured?

- Rolling is the process by which aluminum sheets are made. It begins with aluminum ingots that are heated and then passed through rolling mills. These mills, made of steel, have rotating rollers that squeeze and stretch the aluminum as it passes between them. This continuous rolling process refines the grain structure of the aluminum and improves its mechanical properties. To ensure the desired thickness and surface finish, the aluminum sheets may go through multiple passes in the rolling mills. Each pass gradually reduces the sheet's thickness until the desired thickness is reached. The final pass also gives the sheet its desired surface finish. After rolling, the aluminum sheets may undergo additional treatments like annealing or surface treatments. Annealing involves heating the sheets to a specific temperature and slowly cooling them to improve their strength and relieve internal stresses. Once manufactured and treated, the aluminum sheets are typically cut into desired sizes and shapes. This can be done through shearing with sharp blades or using specialized cutting machines. In summary, the manufacturing of aluminum sheets is a precise and intricate process that involves heating, rolling, treating, and cutting the aluminum to achieve the desired thickness, finish, and properties.

- Q: Can aluminum sheets be used for soundproofing?

- Indeed, soundproofing can be achieved using aluminum sheets. With its high density, aluminum serves as a formidable obstacle to the transmission of sound. By combining aluminum sheets with sound-absorbing materials like foam or fiberglass, the propagation of sound waves can be decreased, thereby mitigating noise pollution. Moreover, the versatility of aluminum sheets allows for effortless installation on walls, ceilings, and various surfaces, making it an ideal choice for soundproofing purposes.

Send your message to us

8x10 Sheets Aluminum Engraving - Alloy 5083 Flat Aluminum Sheet for Manufacturing Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords