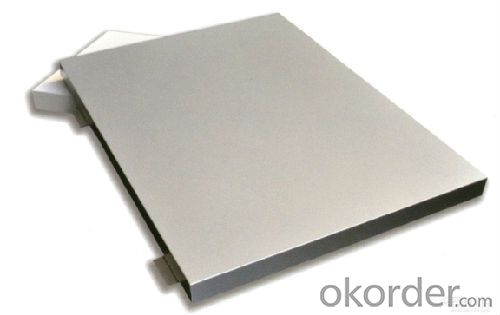

Brushed Aluminum Sheets Canada GB Standard Aluminum Sheet 8011 H14 for PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Sheet specification:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2)Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.18mm to 350mm

4) Width: 200mm to 2300mm

5)Length: no more than 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Packing of Aluminum Sheet:

Wooden Pallet, Wooden Case,or as customer's request.

Application of Aluminum Sheet:

Construction, Decoration, Transportation, Cookware, Machinery, Moulds, Airplane, PP Cap etc.

| Division | Alloy | Application | Feature |

| 1000 SERIES | 1050 | Utensil, decoration, | Easy to process and weld, resistant to rust |

| 1060 | Reflecting plate, printing | High conductibility of electricity and heat | |

| 1070 | plate, heatproof plate, | Low strength | |

| 1100 | cookware | ||

| 1200 | |||

| 3000 SERIES | 3003 | Utensil(F/P, inside of rice | 20% higher strength than the 1100 series |

| 3004 | cooker), aluminum can, | Easily welded and brazed, good antirust | |

| 3005 | material for interior and | Ability Non-heat treatable | |

| 3105 | exterior of building,chemical equipment,Cellular Phone | ||

| 5000 SERIES | 5083 | Ship board | Excellent corrosion resistance andweld ability together with Easy to process and |

| 5052 | heatproof apparatus, material for interior and exterior of building, | Weld and superior hardness &heatproof | |

| 5754 | Parts of Electronic tools | Can be anodized for increased corrosion | |

| 5A05 | Automobile Components: | Resistance | |

| 6000 SERIES | 6061 | IT equipment & facility, | Easy to process , good corrosion resistance, high toughness and processed without distortion after heat-treatable, superior surface treatment |

| 6063 | Mould material, motor material, automatic line, machine & plant etc. | ||

| 8000 SERIES | 8011 | Kitchen utensils,Pharmaceutical Packaging,food packaging,cap | 8000 series is durable to process with special alloy |

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: what’s the difference of activated aluminum and aluminum sheet?

- contain more water and activated

- Q: How could two pieces of aluminium flakes be welded together?

- its welding strength is very high. you can use the following methods to weld two pieces of aluminum sheets together: 1, strict deformation control requirement. 3, it can prevent some flux remnant during welding. 3,the welding wire welding of low temperature M51 and M51-F is operated under 179?C.or they are welded in the situation of being especially thin.4, it can solve the welding of 3 series aluminium alloys and casting, and its welding temperature is 380-400?C.its advantage is that you don't need any flux during welding. WE53 low temperature aluminium welding wire has a high affinity in welding 7 series aluminium alloys. and Q303 low temperature aluminum welding wire has a high affinity for the welding of 1 series aluminium alloys, die casting or 6 series welding materials.

- Q: This question asks for a list of various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheet coatings are applied to enhance properties such as corrosion resistance, appearance, and durability. Common types include: 1. Anodized coatings, which provide a hard, wear-resistant surface. 2. Painted coatings, which can be solvent-based or water-based and offer a range of colors. 3. Powder coatings, which are electrostatically applied and then cured for a durable finish. 4. Laminate coatings, which are plastic films bonded to the aluminum for added protection and aesthetics. 5. Clear coatings, which are transparent and protect the aluminum without altering its appearance. 6. PVD (Physical Vapor Deposition) coatings, which provide a thin, hard layer for enhanced scratch and corrosion resistance. Each type serves different purposes and has unique properties that make it suitable for specific applications.</p>

- Q: The real bumper/ reinforcement bar that is behind the plastic bumpers. Magnet don't stick to it and it don't rust which both types of metal are pretty much like that.

- i agree, the main bumper support under the plastic bumper skin, is aluminum.

- Q: Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured using various methods such as roll embossing or mechanical texturing.

- Q: What kind of paint should be sprayed on the aluminium board?

- Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: What is the bending radius of aluminum sheets?

- The bending radius of aluminum sheets is influenced by several factors, including the sheet thickness, the type of aluminum alloy used, and the bending method employed. In general, aluminum sheets with a thickness of 1mm or less can be bent without cracking if the radius is equal to the thickness of the sheet. For thicker aluminum sheets, it is necessary to have a bending radius that exceeds the thickness of the sheet in order to prevent cracking or fracturing. As a rule of thumb, aluminum sheets with a thickness ranging from 1mm to 6mm should have a bending radius at least 1.5 times the sheet thickness. For instance, a 3mm thick aluminum sheet should have a minimum bending radius of 4.5mm. It is important to note that these guidelines are approximate and can vary depending on the specific aluminum alloy and temper utilized. Additionally, different bending processes, such as air bending, bottoming, or coining, may require different bending radii. To obtain precise bending radius requirements for specific applications of aluminum sheets, it is advisable to consult the manufacturer's specifications or seek professional advice.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Certainly, aluminum sheets can serve as a viable substitute for wood in specific applications. Aluminum boasts numerous advantages over wood, rendering it a favored choice across various industries. Primarily, aluminum exhibits exceptional durability and longevity due to its resistance to corrosion, rot, and pests. Consequently, it proves ideal for outdoor usage or areas with high moisture levels. Moreover, aluminum sheets are lightweight, facilitating easier handling and transportation in comparison to wood. Additionally, they possess a commendable strength-to-weight ratio, enabling them to withstand heavy loads while maintaining their structural integrity. Moreover, aluminum stands as a sustainable material, capable of indefinite recycling without compromising its properties. Conversely, wood necessitates the felling of trees, thereby carrying environmental implications. Aluminum sheets also offer a high degree of design flexibility, readily assuming complex structures through shaping, bending, and forming. This adaptability allows for innovative and creative applications. Furthermore, aluminum exhibits excellent thermal and electrical conductivity, rendering it suitable for scenarios where heat dissipation or electrical conductivity plays a crucial role. Nonetheless, it is crucial to acknowledge that wood retains its unique characteristics and benefits in certain applications. Wood imparts a warm and natural aesthetic that aluminum fails to replicate, making it a preferred choice in interior design or furniture manufacturing. Additionally, wood qualifies as a renewable resource and exhibits excellent insulation properties, proving advantageous in construction or insulation applications. Consequently, while aluminum sheets can serve as a fantastic substitute for wood in numerous instances, the ultimate choice hinges upon the specific requirements and desired outcomes of the application at hand.

- Q: What are the methods to protect aluminum sheets from corrosion during their usage?

- <p>To prevent corrosion of aluminum sheets during use, several strategies can be employed. First, apply a protective coating such as paint, anodizing, or a conversion coating to create a barrier against corrosive elements. Second, ensure proper cleaning and drying to avoid the accumulation of moisture and contaminants. Third, use corrosion inhibitors in environments where aluminum is exposed to aggressive chemicals. Fourth, maintain good ventilation to reduce humidity levels. Finally, regularly inspect and maintain the aluminum sheets to address any signs of corrosion early. These measures can significantly extend the lifespan and performance of aluminum sheets.</p>

Send your message to us

Brushed Aluminum Sheets Canada GB Standard Aluminum Sheet 8011 H14 for PP Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords