8-650mm CK45 Steel Bar / 1045 Round Steel / S45C Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The details of our Steel

1. Produce Standard: as the GB, AISI, ASTM, SAE, EN, BS, DIN, JIS Industry Standard

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment:

Normalized / Annealed / Quenched+Tempered

4. Quality assurance:

All order we can received Third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product information

Chemical Composition(%) of S45C steel rod | C | Si | Mn | S | P | Cr |

0.43-0.50 | 0.17-0.37 | 0.60-0.90 | ≤0.04 | ≤0.04 | ≥0.30 | |

Specification of S45C steel rod | Diameter(mm) | Length(mm) | ||||

8-650 | 500-5800 | |||||

Material of S45C steel rod | A36,SS400,SPCC,SPHC, Q195, Q235,Q345 | |||||

Application of S45C steel rod | (1)Automotive suspension springs (2) Rotary tools and Blades | |||||

Payment Term of S45C steel rod | L/C or T/T, 30% in advance, 70% before the shipment | |||||

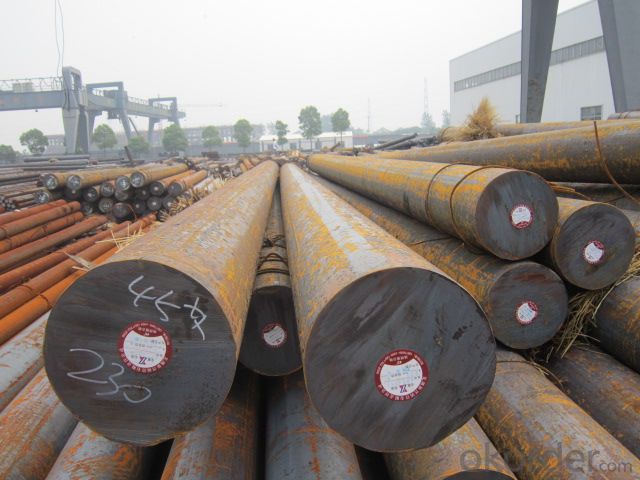

Product show

Workshop show

- Q: How is silicon steel used in electrical transformers?

- Silicon steel is used in electrical transformers as it possesses high magnetic permeability and low electrical conductivity, making it an ideal choice for the core material. The silicon content in the steel increases its resistivity and reduces the energy losses caused by eddy currents. This allows for efficient energy transfer and minimizes heat generation within the transformer.

- Q: How is special steel used in the production of aircraft landing gear?

- Special steel is widely used in the production of aircraft landing gear due to its exceptional mechanical properties and durability. The landing gear is a critical component of an aircraft that supports its weight during takeoff, landing, and ground operations. It must withstand immense forces, impact loads, and harsh environmental conditions. Special steel, such as high-strength low-alloy (HSLA) steel or alloy steel, is specifically chosen for its superior strength-to-weight ratio, high fatigue resistance, and excellent corrosion resistance. These properties are vital for ensuring the landing gear's ability to withstand the extreme forces and stresses encountered during aircraft operations. The use of special steel in the production of landing gear provides several advantages. Firstly, it allows for a lighter weight landing gear, which contributes to the overall weight reduction of the aircraft, resulting in improved fuel efficiency and increased payload capacity. This is crucial for modern aircraft, as reducing weight is a key factor in enhancing performance and reducing operating costs. Secondly, special steel's high fatigue resistance ensures the landing gear can endure repeated loading cycles without any significant degradation in performance. This is critical as the landing gear experiences significant stress during each landing and takeoff, and it must be capable of withstanding these forces over a long operational lifespan. Furthermore, special steel's excellent corrosion resistance properties ensure the landing gear remains protected from environmental factors, such as moisture, salt, and other corrosive agents. Corrosion can weaken the structure of the landing gear, compromising its integrity and safety. Therefore, using special steel helps to ensure the landing gear's longevity and reliability, reducing maintenance requirements and costs. In summary, special steel plays a crucial role in the production of aircraft landing gear by providing exceptional strength, fatigue resistance, and corrosion resistance. Its use allows for lighter, more durable landing gear, resulting in improved aircraft performance, increased efficiency, and enhanced safety.

- Q: What are the properties of cobalt-based alloys?

- Cobalt-based alloys typically exhibit excellent corrosion resistance, high strength, and good wear resistance. They also have high temperature stability, making them suitable for use in high-temperature applications. Additionally, these alloys have magnetic properties, allowing them to be used in electromagnetic applications.

- Q: How does special steel contribute to the power generation equipment industry?

- Special steel plays a crucial role in the power generation equipment industry by providing exceptional strength, durability, and corrosion resistance. It is extensively used in the manufacturing of turbines, generators, and other critical components, ensuring their reliable performance under extreme conditions. Special steel's high temperature and pressure resistance make it ideal for power plants, enabling efficient energy conversion and minimizing downtime. Additionally, its ability to withstand harsh environments and resist fatigue and wear extends the lifespan of power generation equipment, reducing maintenance costs and enhancing overall productivity in the industry.

- Q: What are the different cryogenic grades of special steel?

- There are several cryogenic grades of special steel, including but not limited to, austenitic stainless steel (such as 304L and 316L), ferritic stainless steel (such as 410 and 430), and martensitic stainless steel (such as 440C). These grades are specifically designed to maintain their mechanical properties and resist brittleness at extremely low temperatures.

- Q: Can special steel be used in the aerospace defense industry?

- Yes, special steel can be used in the aerospace defense industry. Special steel alloys, such as titanium, stainless steel, and nickel-based alloys, are commonly used in aerospace applications due to their exceptional strength, corrosion resistance, and high-temperature capabilities. These materials are often employed in manufacturing aircraft components, rocket engines, missile systems, and other defense-related structures to ensure superior performance and durability in extreme conditions.

- Q: How does special steel perform in high-temperature strength?

- Special steel performs well in high-temperature strength due to its unique composition and properties. It is specifically designed to withstand and maintain its mechanical strength and structural integrity at elevated temperatures. This is achieved through the careful selection of alloying elements, heat treatment processes, and precise control of microstructure. Special steel exhibits excellent resistance to deformation, creep, and oxidation, making it a preferred choice for applications that involve high temperatures, such as in power generation, aerospace, and industrial processing.

- Q: What are the limitations of using special steel in high-temperature applications?

- The utilization of special steel in high-temperature scenarios comes with its own set of constraints. One notable limitation is the potential for thermal expansion. Similar to other materials, special steel expands when subjected to high temperatures. This expansion can result in changes in dimensions and internal stress, which can impact the overall performance and integrity of the structure. Another constraint is the likelihood of oxidation and corrosion. Elevated temperatures can expedite the oxidation process, leading to the formation of oxides on the steel's surface. These oxides can cause corrosion and weaken the material over time. To counteract this drawback, special steel alloys with enhanced resistance to oxidation and corrosion are frequently employed in high-temperature applications. Additionally, special steel may experience a decrease in strength at higher temperatures. The mechanical properties of the material, such as tensile strength and hardness, can be significantly diminished as the temperature rises. This reduction in strength can compromise the structural integrity of the component, making it more susceptible to failure. Lastly, special steel may possess a limited temperature range within which its desired properties can be maintained. Beyond a certain temperature threshold, the material may undergo phase transformations or experience degradation, resulting in a loss of its intended characteristics. It is crucial to carefully assess the operating temperature and select the appropriate special steel alloy with a suitable temperature range for the specific high-temperature application. In conclusion, while special steel presents numerous advantages for high-temperature applications, such as exceptional strength, durability, and heat resistance, it is vital to acknowledge its limitations. Considerations such as thermal expansion, oxidation and corrosion, reduced strength at high temperatures, and temperature restrictions must be taken into account and addressed when utilizing special steel in these applications.

- Q: What are the main applications of special steel in the shipbuilding industry?

- Special steel is widely used in the shipbuilding industry for various applications. Some of the main applications include the construction of ship hulls, decks, and superstructures, as well as the fabrication of critical components such as propeller shafts, rudders, and marine engines. Special steel's high strength, corrosion resistance, and durability make it ideal for withstanding the harsh marine environment and ensuring the safety and reliability of ships. Additionally, special steel is also utilized in the production of offshore structures, such as oil rigs and offshore wind turbines, due to its ability to withstand extreme weather conditions and corrosive elements present in offshore environments.

- Q: How does special steel perform in heat treatment applications?

- When it comes to heat treatment applications, special steel is specifically engineered to excel. Unlike regular steel, special steel is enriched with specific elements that enhance its heat resistance and improve its mechanical properties. Through processes like annealing, quenching, tempering, or hardening, special steel undergoes structural changes that result in increased strength, hardness, toughness, and wear resistance. The exceptional performance of special steel in heat treatment applications can be attributed to its unique alloying elements, including chromium, molybdenum, nickel, and vanadium. These elements create various carbides, nitrides, or intermetallic compounds during heat treatment, contributing to the overall enhancement of the steel's properties. For example, chromium forms chromium carbides, which boost hardness and corrosion resistance, while molybdenum and vanadium enhance hardenability and wear resistance. Furthermore, special steel exhibits remarkable dimensional stability during heat treatment. It possesses a low tendency to warp or distort, ensuring that the final product retains its desired shape and dimensions. This dimensional stability is especially crucial for applications that require precise tolerances or intricate designs. Moreover, special steel offers consistent and dependable heat treatment results. Its composition and microstructure are meticulously controlled, guaranteeing a predictable response to heat treatment processes. This enables manufacturers to consistently achieve the desired mechanical properties, minimizing the risk of inconsistencies or failures in the end product. In conclusion, special steel excels in heat treatment applications. Its exceptional alloying elements, dimensional stability, and reliable heat treatment response make it an ideal choice for applications that necessitate improved strength, hardness, toughness, and wear resistance. Whether it is for automotive components, tooling, or industrial machinery, special steel delivers dependable and enhanced performance after undergoing heat treatment processes.

Send your message to us

8-650mm CK45 Steel Bar / 1045 Round Steel / S45C Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords