6061-T6 Aluminum Coil for Roofing, Wall and Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil for Roofing Wall and Decoration

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

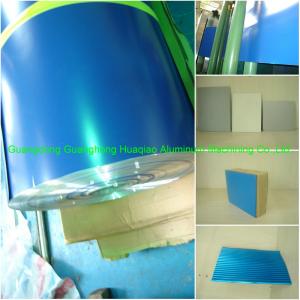

2. Application of Color Coated Aluminium Coils for Aluminum Roller Shutter 0.15 to 1.20mm

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil for Roofing Wall and Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

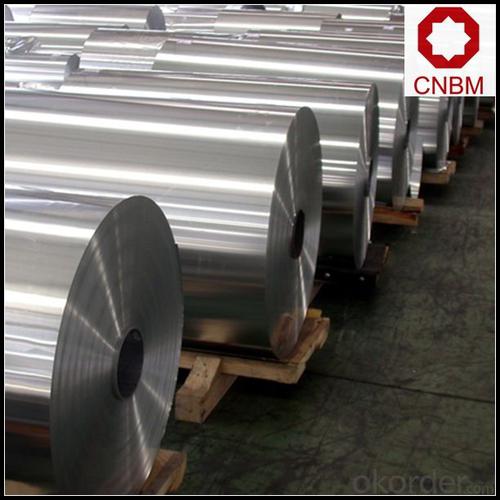

5. Image of Aluminum Coil for Roofing Wall and Decoration

6. Package and shipping of Aluminum Coil for Roofing Wall and Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the different types of aluminum alloys used for making coils?

- There are various types of aluminum alloys used for making coils, including 1100, 3003, 5052, and 6061. These alloys differ in terms of their composition and properties, such as strength, corrosion resistance, and formability, allowing manufacturers to select the most suitable alloy based on the specific requirements of the application.

- Q: Can aluminum coils be used for decorative purposes?

- Aluminum coils offer a multitude of possibilities when it comes to decoration. This versatile material can be easily molded and adjusted, making it ideal for a wide range of decorative uses. In industries like architecture, interior design, and automotive design, aluminum coils are frequently employed to create decorative trims, accents, and borders. To further enhance their visual appeal and match the desired aesthetic, these coils can be painted or coated with different finishes. Moreover, thanks to their lightweight nature and durability, aluminum coils are a popular choice for outdoor decorative purposes, such as garden ornaments, sculptures, and signage. Ultimately, incorporating aluminum coils into various projects provides a cost-effective and visually pleasing solution for adding decorative elements.

- Q: This question is asking about the potential negative effects or hazards associated with the use of aluminum coils.

- <p>The use of aluminum coils can pose certain risks and dangers, primarily due to their high thermal conductivity and reactivity. When used in cooking or heating applications, aluminum coils can cause uneven heat distribution, which may lead to burning or melting of food. Additionally, aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food and causing health concerns such as neurological disorders and bone diseases. Moreover, aluminum coils can corrode over time, especially when exposed to moisture or certain chemicals, which can weaken their structure and pose a risk of breakage or injury. It's important to use aluminum coils appropriately and to monitor their condition regularly to minimize these risks.</p>

- Q: The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- First - the only ranges that care - are indoor ranges. And 99.99999% of them do not allow 308 rifle caliber fired indoors!! Second - the range does not care what the case is made out of - they are caring about what the bullet is made out of. Most lead bullets are soft and do not hurt a backstop - steel ones do. You should have included the name of the range - we could have helped you more.

- Q: Can aluminum coils be used in the production of cryogenic storage tanks?

- Yes, aluminum coils can be used in the production of cryogenic storage tanks.

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Yes, aluminum coils can be used in the production of aircraft fuel tanks. Aluminum is a lightweight and durable material that is commonly used in the aerospace industry due to its high strength-to-weight ratio. Its corrosion-resistant properties also make it an ideal choice for fuel tanks, as it can withstand the harsh conditions and chemicals found in aviation fuel. The use of aluminum coils allows for efficient manufacturing processes, as they can be easily formed and welded into the desired tank shape. Additionally, aluminum has excellent thermal conductivity, which helps dissipate heat generated during flight and prevents the fuel from overheating. Overall, aluminum coils are a suitable and widely-used material in the production of aircraft fuel tanks.

- Q: Can aluminum coils be painted or coated for aesthetic purposes?

- Yes, aluminum coils can be painted or coated for aesthetic purposes. This process involves applying a suitable paint or coating to the surface of the coils to enhance their appearance and provide protection against corrosion or other environmental factors.

- Q: Are aluminum coils suitable for low-maintenance roofing applications?

- Yes, aluminum coils are suitable for low-maintenance roofing applications. Aluminum is highly resistant to corrosion, lightweight, and durable, making it an ideal material for roofing. It requires minimal maintenance, as it does not rust or rot like other metals. Additionally, aluminum roofs are known for their longevity and ability to withstand harsh weather conditions, further reducing the need for maintenance.

- Q: What are cold rolled aluminum coils and hot rolled aluminium coils, what are their respective features?

- Each has its advantages and disadvantages.Cold rolling mainly deals with non thermal strengthening of sheet metal. Generally, the surface requirement is relatively high, and the ultra-thin materials such as single zero foil, double zero foil and so on can only be rolled by cold rolling.

- Q: This question asks for methods to determine whether an aluminum coil is made from recycled material.

- <p>Determining if an aluminum coil is made from recycled material can be challenging without specific testing, as recycled and virgin aluminum can look identical. However, there are a few indicators: 1) Look for certification or labels on the coil indicating it's made from recycled material. 2) Check with the supplier for documentation or a certificate of analysis that confirms the material's origin. 3) Analyze the coil's composition; recycled aluminum may have slight variations in purity or alloy composition. 4) Use spectrographic analysis to determine the exact composition of the aluminum, which can sometimes reveal if it's recycled. Ultimately, transparency from the supplier is key to confirming the source of the aluminum.</p>

Send your message to us

6061-T6 Aluminum Coil for Roofing, Wall and Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords