Aluminum Sheets in Idaho - 6061/6063/5083 H116/H112 Aluminum Sheet for Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

6061/6063/ 5083 H116 /H112 Aluminum Sheet for Boat

l Product Details

1.Alloy: 1060, 1050, 3003, 5052, 5754, 5083, 5A06, 5A02, 5A03, 5082, 6061 etc

2.Temper: O, H14, H24, H16, H18

3.Thickness:0.2-200mm

4.Width:20-2400mm

| Aluminium sheet | |||||

Packing: Export plywood pallets or box. The bundle weight not exceed 2MT. Loading: by 1x20GP can load about 18MT | |||||

| Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | |||||

| Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |||||

| Application : Mainly used insigns, billboards, building exterior decoration, bus body, high-rise buildings and factories wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk, plate, kitchenware, decorations, reflective devices, ect | |||||

| MOQ | 2.5 tons | ||||

| Payment term: | T/T, L/C | ||||

| Kind attention: Specifications can be customized as the customer’s requirements. | |||||

l Packaging & Delivery

Packaging detail: Covering with brown paper and plastic bag then packed with wooden plywood then directly loading into container for transshipment. For the thickness which is more than 1.50mm, one paper interleave into two sheets.

Delivery detail: within 30days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium sheet has always been one of the most popular products in CNBM. With advanced technic skills and equipment, CNBM has produced high quality aluminium sheets that meet international standard.

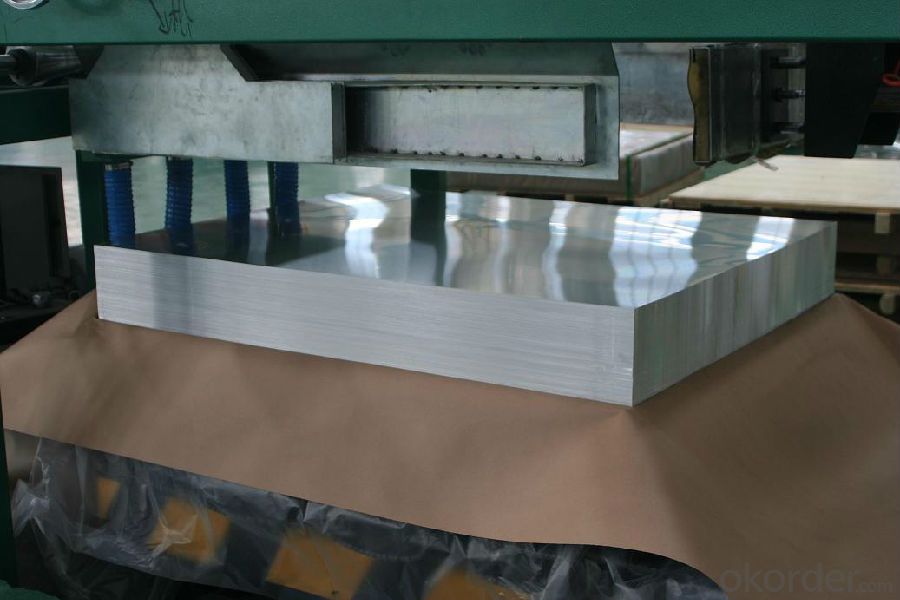

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Are aluminum sheets suitable for insulation cladding?

- Aluminum sheets are a suitable option for insulation cladding. This material is highly versatile and durable, commonly used in construction for multiple purposes, including insulation cladding. The thermal properties of aluminum sheets are excellent, effectively preventing heat transfer. Additionally, their low thermal conductivity ensures improved energy efficiency by minimizing heat transfer between the building's interior and exterior. Moreover, aluminum is lightweight and easy to handle, making it convenient for installation purposes. It is also resistant to corrosion, allowing it to withstand various weather conditions and remain a long-lasting choice. Furthermore, aluminum sheets are available in different thicknesses, providing customization options based on specific insulation requirements. Not only do aluminum sheets possess functional benefits, but they also enhance the overall appearance of the building. With their sleek and modern look, these sheets can be easily painted or coated in different colors to match the desired aesthetic design. In conclusion, aluminum sheets are an excellent choice for insulation cladding due to their thermal properties, durability, ease of installation, and aesthetic appeal.

- Q: Can aluminum sheet be used for electrical wiring?

- No, aluminum sheet cannot be used for electrical wiring.

- Q: This question asks for guidance on selecting aluminum sheets based on their intended use, implying a need for criteria or factors to consider when making such a choice.

- <p>When choosing aluminum sheets for different purposes, consider the following factors: 1) Thickness: Depending on the strength and durability required, select the appropriate thickness. 2) Alloy Type: Different alloys have varying properties; for instance, 1100 series is purest and softest, while 6000 series offers high strength. 3) Surface Finish: Choose between mill finish, anodized, or coated finishes based on aesthetic and functional needs. 4) Temper: This refers to the hardness and strength, with options like O (annealed), H14 (strain hardened), and T6 (solution heat treated). 5) Application: Consider the specific use, such as construction, automotive, or aerospace, as each may require specific properties. Always consult with a supplier or engineer for advice tailored to your project's needs.</p>

- Q: Can aluminum sheets be polished?

- Yes, aluminum sheets can be polished. Aluminum is a relatively soft metal, which makes it easier to polish compared to harder metals like stainless steel. Polishing aluminum sheets involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections, scratches, or oxidation on the surface. The process typically involves several stages of polishing with different grits of sandpaper or polishing compounds, gradually achieving a smoother and more reflective surface. Polished aluminum sheets are commonly used in various applications, including automotive parts, architectural elements, and decorative items, as the polishing process enhances the metal's appearance and provides a lustrous and reflective finish.

- Q: Is it possible to use aluminum sheets for exterior siding purposes?

- <p>Yes, aluminum sheets can be used for siding applications. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It's also resistant to rot, termites, and fire, making it a popular choice for many homeowners and builders. However, it's important to ensure that the aluminum is of high quality and installed correctly to maximize its benefits.</p>

- Q: Can the aluminum sheets be painted or coated with a different color?

- Indeed, it is possible to paint or coat aluminum sheets with a different color. Aluminum, being a flexible material, lends itself well to the application of paint or coating in order to achieve the desired color or finish. This can be accomplished using a range of techniques, including powder coating, anodizing, or the use of liquid paint. These methods serve to both protect the aluminum sheet's surface and alter its color or appearance. The selection of the specific paint or coating will hinge upon the particular requirements and desired outcome. On the whole, the practice of painting or coating aluminum sheets is commonplace, granting opportunities for customization and aesthetic enhancement.

- Q: Are the aluminum sheets suitable for manufacturing solar panel backings?

- Yes, aluminum sheets are suitable for manufacturing solar panel backings. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for outdoor applications like solar panels. Additionally, aluminum's high thermal conductivity helps in dissipating heat, which is beneficial for solar panels.

- Q: How do aluminum sheets perform in terms of chemical resistance?

- Aluminum sheets generally have good chemical resistance properties. However, their performance can vary depending on the specific chemical environment and conditions. Aluminum is known to have excellent resistance to corrosion from most acids, alkalis, and organic solvents. It forms a protective oxide layer on its surface, which prevents further reaction with many chemicals. However, aluminum can be susceptible to corrosion in certain aggressive environments, such as strong acids like hydrochloric acid or sulfuric acid, and alkaline solutions with high pH levels. In these cases, the protective oxide layer may break down, leading to the degradation of the aluminum surface. Additionally, some chemicals, like mercury and certain salts, can also cause localized corrosion or pitting on aluminum surfaces. Therefore, it is important to consider the specific chemicals and concentrations that the aluminum sheets will be exposed to when assessing their chemical resistance performance. To enhance the chemical resistance of aluminum sheets, various surface treatments, coatings, or alloys can be applied. These modifications can provide additional protection against specific chemicals or environmental conditions, further improving the overall chemical resistance properties of aluminum sheets. In summary, aluminum sheets generally exhibit good chemical resistance, but their performance can be influenced by the specific chemical environment and conditions. It is advisable to assess the compatibility of aluminum with the intended chemicals and consider appropriate surface treatments or coatings if necessary.

- Q: What are the physical properties of aluminum sheets?

- Aluminum sheets possess a range of physical properties that make them highly sought-after in numerous applications. Firstly, they are lightweight, weighing only about one-third of steel at a density of approximately 2.7 grams per cubic centimeter. This characteristic makes aluminum sheets easy to handle and transport, reducing overall weight in structures or products. Additionally, aluminum sheets demonstrate exceptional resistance to corrosion. When exposed to air, a thin, protective oxide layer forms on their surface. This oxide layer acts as a barrier, preventing further oxidation and corrosion. As a result, aluminum sheets are well-suited for outdoor applications and environments with high humidity or exposure to corrosive substances. Moreover, aluminum sheets possess good thermal conductivity, enabling efficient heat transfer. This feature makes them commonly used in heat exchangers, radiators, and other cooling systems. Another noteworthy physical property of aluminum sheets is their high electrical conductivity. Aluminum is an excellent conductor of electricity, second only to copper. Consequently, it finds widespread use in electrical applications such as wiring, power transmission lines, and electrical equipment. In terms of appearance, aluminum sheets boast a bright, silvery-white color and a smooth surface finish, providing an aesthetically pleasing look. They can be easily shaped, formed, and machined, making them highly versatile and suitable for various manufacturing processes. Overall, the physical properties of aluminum sheets, including their lightweight nature, corrosion resistance, thermal conductivity, electrical conductivity, and ease of fabrication, contribute to their widespread use in industries such as aerospace, automotive, construction, and electrical engineering.

- Q: Are the aluminum sheets suitable for manufacturing architectural column covers?

- Yes, architectural column covers can be manufactured using aluminum sheets. Aluminum is a material that is both lightweight and durable, offering excellent resistance to corrosion. This makes it an ideal choice for exterior applications like column covers. It is also easily shaped, bent, and fabricated, allowing for the creation of customized designs and sizes. This versatility is beneficial for architectural projects. Furthermore, aluminum sheets can be finished with various coatings, such as powder coating or anodizing, to enhance their visual appeal and provide extra protection against weathering and wear. Overall, aluminum sheets are a suitable option for manufacturing architectural column covers due to their combination of strength, versatility, and aesthetics.

Send your message to us

Aluminum Sheets in Idaho - 6061/6063/5083 H116/H112 Aluminum Sheet for Boat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords