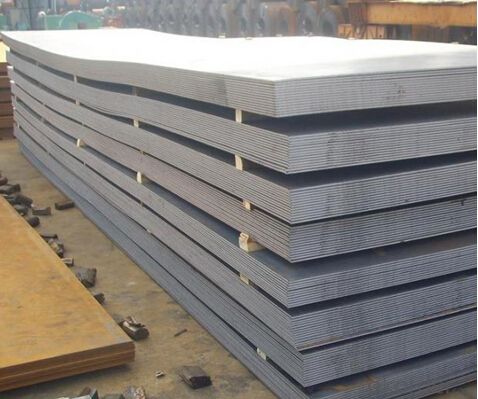

5CrNiMoV Cold Rolled Steel Plate Different Types of Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

5CrNiMoV Cold Rolled Steel Sheet Prices Different Types of Steel Plate

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | |

A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu |

|

|

A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 |

|

|

Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

Length: | 6000mm, 8000m, can cut to width and length | |||||||

Packing: | according to customer‘s require or export’s standard | |||||||

Delivery time: | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

Related Products Overviews

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | 1. CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. 2. For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours |

Advantages

| 1. Industry experience over 20 years. 2. Shipment of goods -More than 70 countries worldwide. 3. The most convenient transport and prompt delivery. 4. Competitive price with best service. 5. High technical production line with top quality products. 6. High reputation based on best quality products. |

| Packaging | Sea worthy packing /as per customer's packing instruction |

| Delivery | 15 ~ 40 days after receiving the deposit |

- Q: What are the different coating materials used for special steel?

- There are several different coating materials used for special steel, including zinc, aluminum, nickel, tin, and epoxy-based coatings. These coatings are applied to enhance the corrosion resistance, improve durability, and provide a decorative finish to the special steel.

- Q: What are the different peening techniques used for special steel?

- There are several peening techniques used for special steel, including shot peening, ultrasonic peening, laser peening, and cavitation peening. Each technique involves using different methods and tools to introduce controlled compressive stresses into the material's surface, improving its mechanical properties and resistance to fatigue, stress corrosion, and other forms of degradation.

- Q: What are the different methods of surface peening for special steel?

- Some of the different methods of surface peening for special steel include shot peening, glass bead peening, and laser peening. Shot peening involves bombarding the surface of the steel with small spherical shots to create compressive stresses, which helps to increase the strength and durability of the material. Glass bead peening uses small glass beads instead of shots to achieve a similar effect. Laser peening, on the other hand, involves using high-energy laser pulses to generate shock waves on the surface of the steel, resulting in improved fatigue resistance and damage tolerance. Overall, these methods can enhance the performance and lifespan of special steel components.

- Q: How does special steel contribute to the automotive safety?

- Special steel contributes to automotive safety in several ways. Firstly, it provides increased strength and durability to the vehicle's structure, which helps to absorb and distribute impact forces during collisions, thus protecting the occupants. Secondly, special steel is often used for manufacturing components like airbags, seat belts, and anti-lock braking systems, ensuring their reliability and effectiveness in critical situations. Additionally, this type of steel can enhance the vehicle's resistance against corrosion, reducing the risk of structural damage over time. Overall, special steel plays a vital role in enhancing the safety standards of automobiles.

- Q: What are the specific requirements for special steel used in the chemical industry?

- Special steel used in the chemical industry must meet specific requirements in order to ensure optimal performance and safety. Some of the key requirements for special steel in the chemical industry include: 1. Corrosion resistance: Special steel used in the chemical industry must possess high resistance to corrosion, as it will be exposed to various aggressive chemicals and corrosive environments. This means that the steel should be able to withstand the corrosive effects of acids, alkalis, and other chemicals commonly used in the industry. 2. High temperature resistance: The steel should have excellent heat resistance to withstand high operating temperatures often encountered in chemical processes. This is important to ensure that the steel does not degrade or lose its strength when exposed to elevated temperatures. 3. Mechanical strength: Special steel used in the chemical industry should have superior mechanical strength to withstand the high stress and pressure that can occur during chemical processes. It should be able to maintain its structural integrity even under challenging conditions. 4. Resistance to fatigue and stress: The steel should have good resistance to fatigue and stress, as it will be subjected to cyclic loading and pressure variations during operation. This is crucial to ensure the longevity and reliability of the steel in the chemical industry. 5. Resistance to pitting and crevice corrosion: Special steel should be resistant to pitting and crevice corrosion, which can occur in areas of the steel that are exposed to stagnant or low-velocity corrosive media. Pitting and crevice corrosion can lead to localized damage and failure of the steel, so resistance to these types of corrosion is essential. 6. Low impurity content: Special steel used in the chemical industry should have low impurity content to minimize the risk of contamination of the chemicals being processed. Impurities can react with the chemicals or cause unwanted reactions, potentially leading to product quality issues or safety hazards. 7. Easy cleanability: The steel should have a smooth surface and be easily cleanable to prevent the buildup of contaminants or fouling. This is important to maintain the purity of the chemicals being processed and to ensure efficient operation of the equipment. Meeting these specific requirements ensures that special steel used in the chemical industry can withstand the harsh conditions and corrosive environments encountered, while maintaining its structural integrity, performance, and safety.

- Q: How does special steel contribute to the renewable energy conversion efficiency?

- Special steel plays a crucial role in improving the renewable energy conversion efficiency by offering enhanced mechanical properties, corrosion resistance, and temperature resistance. It is used in the manufacturing of various renewable energy components such as wind turbine blades, solar panels, and hydroelectric power systems. The strength and durability of special steel ensure that these components can withstand harsh environmental conditions, resulting in increased efficiency, reliability, and lifespan. Additionally, special steel's high thermal conductivity allows for efficient heat transfer in concentrated solar power plants, further optimizing energy conversion.

- Q: How does special steel contribute to the automotive sector?

- Special steel plays a significant role in the automotive sector by contributing to the manufacturing and performance of various automotive components. It offers several benefits that enhance the overall quality, durability, and safety of vehicles. Firstly, special steel is known for its exceptional strength and toughness. This makes it ideal for producing critical automotive parts such as engine components, chassis, suspension systems, and safety reinforcements. These components require high strength to withstand the stresses and strains experienced during vehicle operation, ensuring the safety of passengers. Furthermore, special steel provides excellent resistance to wear, corrosion, and high-temperature environments. This makes it suitable for manufacturing parts like gears, bearings, shafts, and exhaust systems, which are exposed to harsh conditions. The use of special steel in these components improves their lifespan, reliability, and overall performance, reducing maintenance and replacement costs for vehicle owners. Moreover, special steel enables the lightweighting of vehicles. Automakers are constantly striving to reduce the weight of vehicles to enhance fuel efficiency and reduce emissions. Special steel alloys, such as high-strength low-alloy (HSLA) steel, offer a unique combination of strength and lightweight properties, allowing manufacturers to design lighter and more fuel-efficient vehicles without compromising on safety or performance. In addition to its mechanical properties, special steel also contributes to the automotive sector through its versatility in manufacturing processes. It can be easily formed, welded, and machined, enabling complex shapes and designs for automotive parts. This flexibility enhances the design possibilities and allows for innovative solutions to meet the evolving needs of the automotive industry. Overall, special steel plays a crucial role in the automotive sector by providing strength, durability, and lightweight properties to various components. Its use in critical parts ensures the safety of vehicles and passengers, while its resistance to wear and corrosion improves the longevity and performance of automotive systems. With the constant drive for fuel efficiency and innovation in the automotive industry, special steel continues to be an essential material in shaping the future of automobiles.

- Q: Can special steel be used in the wood manufacturing industry?

- Yes, special steel can be used in the wood manufacturing industry. Special steel, such as high-speed steel or tool steel, is often used in the production of cutting tools like saw blades or drill bits, which are essential in wood processing. These types of steel offer superior hardness, durability, and resistance to wear, allowing for efficient and precise cutting of wood. Additionally, special steel can also be used in the production of machinery or equipment used in wood manufacturing processes, providing strength and reliability.

- Q: How does special steel perform in aerospace applications?

- Due to its exceptional performance and unique properties, special steel finds extensive use in aerospace applications. A primary reason for its usage lies in its high strength-to-weight ratio, a crucial factor in the aerospace industry where weight reduction is of utmost importance. Special steel alloys exhibit superior strength, enabling them to withstand the extreme conditions experienced during flight, including high temperatures, vibrations, and pressure changes. Moreover, special steel possesses excellent corrosion resistance, making it an ideal choice for aerospace applications where exposure to moisture and various chemicals is common. Its corrosion resistance ensures the durability and longevity of critical components, resulting in reduced maintenance and replacement costs. Furthermore, special steel offers excellent fatigue resistance, allowing it to endure repeated loading and unloading cycles without deformation or failure. This property is vital in aerospace applications where components must withstand cyclic stresses and maintain their integrity for extended periods. Additionally, special steel alloys can be readily fabricated and machined, facilitating the production of intricate and precise aerospace components. The ease of fabrication ensures efficient manufacturing processes and the ability to create complex designs, which are essential for optimizing performance and aerodynamics. In conclusion, special steel's exceptional strength, corrosion resistance, fatigue resistance, and ease of fabrication make it an invaluable material in aerospace applications. Its utilization in critical components, such as turbine blades, landing gears, and structural elements, guarantees the safety, reliability, and efficiency of aerospace systems.

- Q: How does special steel perform in high-temperature hydrogen environments?

- Special steel typically performs well in high-temperature hydrogen environments due to its excellent resistance to hydrogen embrittlement and oxidation. It maintains its mechanical strength and integrity, preventing potential failures or degradation in such conditions. Additionally, special steel alloys can exhibit enhanced corrosion resistance, making them suitable for various industrial applications involving high-temperature hydrogen exposure.

Send your message to us

5CrNiMoV Cold Rolled Steel Plate Different Types of Steel Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords