HR sheet ! hot sales hot rolled carbons steel checker plate/sheet mild steel chequer plate/sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.General Introduction

Item name | Chequered steel plate | |

Standard | ASTM, JIS, GB | |

Grade | Gr1, Gr2, Gr3, Gr5, Gr7, Gr12 | |

Dimension | Hot rolled | Thk*W*L (4.1-60.0)*(400-3000)*(1000-7000)mm |

Cold rolled | Thk*W*L (0.3-4.0)*(400-1400)*(1000-4000)mm | |

Surface | Acid pickling | |

Application | Heat exchanger, chemical or medical industry | |

Advantages | High qualities, competitive price, strict inspection, prompt delivery. | |

2.Chemical Requirements

| N | C | H | Fe | O | Al | V | Pa | Mo | Ni | Ti | |

Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | / | / | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5-6.75 | 3.5-4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12-0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2-4.0 | 0.6-0.9 | bal |

3.Tensile Properties

| Grade | Tensile Strength(min) | Tensile Strength(min) | Yield Strength(min) | Yield Strength(min) | Elongation(%) |

| Ksi | Mpa | Ksi | Mpa | ||

| Gr1 | 35 | 240 | 20 | 138 | 24 |

| Gr2 | 50 | 345 | 40 | 275 | 20 |

| Gr3 | 65 | 450 | 55 | 380 | 18 |

| Gr5 | 130 | 895 | 120 | 828 | 10 |

| Gr7 | 50 | 345 | 40 | 275 | 20 |

| Gr9 | 90 | 620 | 70 | 438 | 15 |

| Gr12 | 70 | 438 | 50 | 345 | 18 |

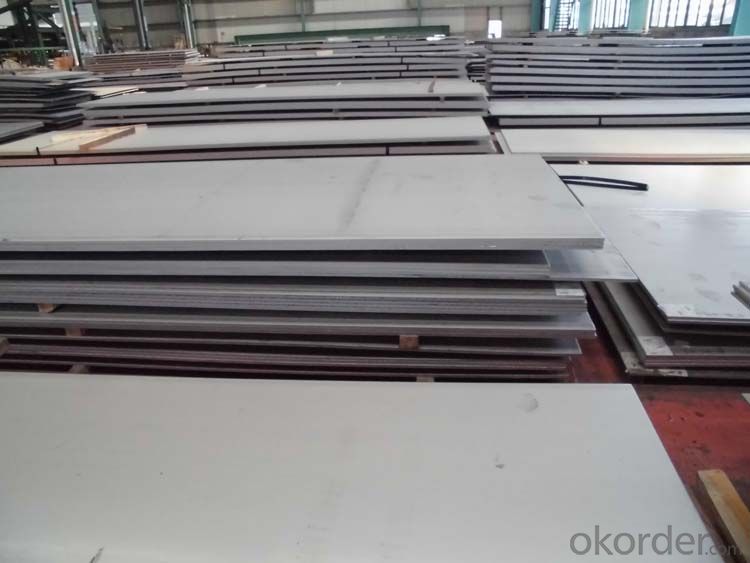

4.Production

5.Product

Packaging & Shipping

- Q: What are the different edge treatments for steel sheets?

- There are several edge treatments available for steel sheets, including deburring, chamfering, hemming, and beading. These treatments help to remove sharp edges, create a smooth finish, enhance aesthetics, and improve safety during handling and assembly processes.

- Q: What is the difference between a coated and uncoated stainless steel sheet?

- A coated stainless steel sheet is one that has been treated with a protective layer, such as a polymer or paint, to enhance its resistance to corrosion, scratches, and stains. On the other hand, an uncoated stainless steel sheet does not have any additional protective layer, leaving it more susceptible to these issues.

- Q: Can steel sheets be used in acidic environments?

- Yes, steel sheets can be used in acidic environments but it is important to choose the appropriate type of steel and take certain precautions. Stainless steel, particularly grades with high levels of chromium and nickel, is highly resistant to corrosion and can withstand acidic environments. These types of steel sheets form a passive protective layer on their surface when exposed to oxygen, which prevents further corrosion. However, not all types of steel are suitable for acidic environments. Carbon steel, for example, is prone to corrosion in acidic conditions and would not be recommended for such applications. Additionally, the concentration and temperature of the acid can also affect the performance of steel sheets. To ensure the best performance in acidic environments, it is advisable to consult with steel suppliers or corrosion engineers who can recommend the most appropriate type of steel for specific conditions. It is also important to regularly monitor and maintain the steel sheets to prevent any potential damage or corrosion.

- Q: Are steel sheets suitable for pedestrian bridges or walkways?

- Yes, steel sheets are suitable for pedestrian bridges or walkways. They offer high strength, durability, and resistance to wear and tear, making them ideal for supporting both pedestrian traffic and the weight of the structure. Additionally, steel sheets can be easily fabricated and installed, allowing for efficient construction of safe and reliable walkways or bridges.

- Q: How do steel sheets perform in abrasive environments?

- Steel sheets perform well in abrasive environments due to their high strength and durability. The hardness of steel allows it to resist the wear and tear caused by abrasive materials, such as sand, gravel, or dust particles. Additionally, the smooth surface of steel sheets helps to reduce friction and prevent the accumulation of debris, further enhancing their performance in abrasive environments. Steel sheets can withstand the impact of abrasive materials without deformation or damage, making them ideal for applications such as construction, mining, and manufacturing industries. However, it is important to note that certain types of steel, such as stainless steel, are more resistant to corrosion and rust, which can also be factors in abrasive environments. Regular maintenance and protective coatings can further enhance the performance and longevity of steel sheets in abrasive environments.

- Q: Can steel sheets be bent or curved?

- Yes, steel sheets can be bent or curved. Steel is a malleable material, meaning it can be easily shaped or formed without breaking or cracking. This property allows steel sheets to be bent or curved into various shapes and angles, depending on the desired outcome. The process of bending or curving steel sheets typically involves the use of specialized tools such as press brakes or rollers. These tools apply force to the steel sheet, causing it to bend or curve according to the desired specifications. This ability to manipulate steel sheets makes them highly versatile and widely used in industries such as construction, automotive, and manufacturing.

- Q: What is the average bending radius for steel sheets?

- The bending radius of steel sheets is subject to variation depending on factors such as thickness, grade, and steel type. Nevertheless, in the case of mild steel sheets, the minimum bending radius typically equates to roughly four times the sheet thickness. To illustrate, if the sheet thickness measures 1.6mm, the minimum bending radius would be approximately 6.4mm. It is crucial to recognize that this serves as a general principle, and particular bending specifications may deviate depending on the intended application and desired result.

- Q: How are steel sheets produced?

- Steel sheets are produced through a process called hot rolling, where a steel slab is heated and passed through a series of rolling mills to reduce its thickness and obtain the desired sheet size.

- Q: Can steel sheets be used in furniture applications?

- Yes, steel sheets can be used in furniture applications. Steel sheets are commonly used in the construction of various furniture pieces such as tables, chairs, shelving units, and storage cabinets. They provide strength, durability, and a modern aesthetic to furniture designs. Additionally, steel sheets can be easily formed and shaped into different configurations, making them versatile for various furniture styles and functions.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are known for their exceptional strength and durability, making them highly resistant to heavy loads or pressure. Due to their composition and manufacturing process, steel sheets possess a high tensile strength, which allows them to withstand substantial amounts of force without deforming or breaking. This property makes steel sheets ideal for applications where heavy loads or pressure are involved, such as construction, transportation, and industrial machinery. Additionally, steel sheets have excellent load-bearing capacity, meaning they can distribute the applied pressure evenly across their surface, minimizing the risk of structural failure or damage. The ability of steel sheets to perform under heavy loads or pressure is further enhanced by their rigidity, which prevents them from bending or buckling, ensuring the integrity of the structure or equipment they are supporting. Overall, steel sheets are a reliable and robust choice when it comes to handling heavy loads or pressure, making them a popular material in various industries.

Send your message to us

HR sheet ! hot sales hot rolled carbons steel checker plate/sheet mild steel chequer plate/sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords