5086 Aluminum Sheets - Polyester Coated Aluminum Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

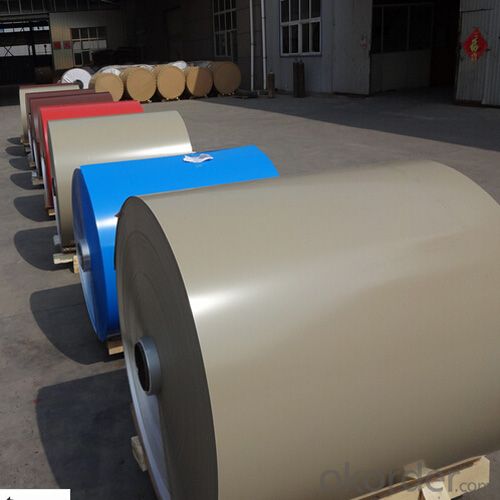

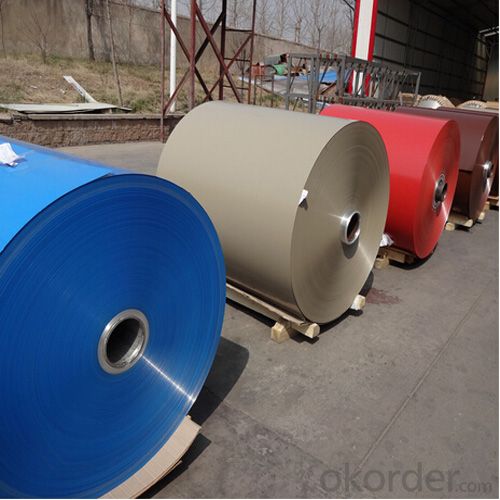

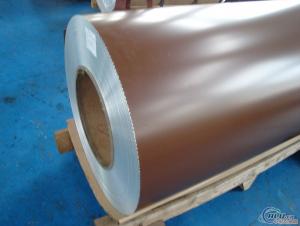

1.Structure of Polyester Coated Aluminum Coil for Construction Description:

Color coated aluminum coil is aluminum coil after cleaning, coating, and baking. Surface of aluminum coil can be painted to any color. Dong Chuan color-coated aluminum coil and aluminum sheet coils mainly come from Southwest Aluminum, Nanping, Chinalco, Ruimin, etc. which are the best raw materials suppliers domestically. Our coating paints are mainly from American PPG and Swedish Becker.

2.Main Features of Polyester Coated Aluminum Coil for Construction:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

3. Polyester Coated Aluminum Coil for Construction Images:

4. Polyester Coated Aluminum Coil for Construction Specification:

Item | Color Coated Aluminium coil,Aluminium coil,Aluminium alloy coil, |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc |

Material | 1060,1050,1070,1100,a1100P,3003,3005,5052,5652,5154,5254,5454,5083,5754, 5086,5056,5456,2A12,2024,2014,6061,6062,6063,6082,7003,7004,7075,8010,8020,etc |

Thickness | 0.1-200mm |

Width | 10-2600mm |

Length | 1-12m,or as required |

Temper | 0-H112,T3-T8,T351-T851 |

Surface | mill,bright,polished,hair line,brush,sand blast,checkered,embossed,etching,etc |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can 101 aluminum sheets be embossed or textured?

- It is possible to emboss or texture 101 aluminum sheets. Aluminum is a highly adaptable material that can be easily molded and formed. To emboss or texture aluminum sheets, pressure or heat is applied to create patterns that are either raised or recessed on the surface. There are different methods available for this process, including mechanical embossing or chemical etching. As long as the aluminum sheets are of suitable thickness and good quality, it is feasible to achieve desired designs and patterns through embossing or texturing.

- Q: This question asks for a comparison between aluminum sheets and other types of sheet metal regarding their strength and durability.

- <p>Aluminum sheets are known for their high strength-to-weight ratio, making them lighter than many other sheet metals such as steel. They offer excellent corrosion resistance, which contributes to their durability. However, in terms of sheer strength, aluminum is not as strong as steel or titanium. Steel is stronger but also heavier, and while titanium is very strong and durable, it is also more expensive and less commonly used in construction and manufacturing. Aluminum's malleability allows it to be easily shaped and formed, and it is also non-magnetic and has good thermal conductivity. Overall, aluminum is a popular choice for applications requiring a balance between strength, weight, and resistance to corrosion.</p>

- Q: What is the coefficient of friction for aluminum sheets?

- The coefficient of friction of aluminum sheets can differ based on specific conditions, including the surface it comes into contact with and the existence of lubricants or contaminants. Generally, aluminum sheets have a relatively low coefficient of friction, which ranges from 0.2 to 0.6. Nevertheless, it is crucial to acknowledge that these values are approximate and can be affected by numerous factors.

- Q: Can aluminum sheets be soldered?

- Soldering aluminum sheets is indeed possible, but it necessitates specific techniques and materials. Due to its high thermal conductivity and low melting point, traditional soldering methods pose a challenge when working with aluminum. Nevertheless, specialized soldering techniques, like the utilization of flux and a soldering iron with a high temperature, can successfully solder aluminum. Furthermore, a particular type of solder known as aluminum solder or aluminum flux-cored solder is essential, as regular solder does not adhere well to aluminum surfaces. Thoroughly cleaning the aluminum surface before soldering is crucial to ensure a sturdy bond. In summary, although soldering aluminum sheets may be more intricate compared to other metals, it is achievable with the appropriate tools, materials, and techniques.

- Q: This is kind of odd, but if a volcano erupted and the lava dripped into an aluminum can, would the can melt? Would the lava harden and cool in it?

- Temperature of lava - 700 degrees Celsius. Melting point of aluminum - 660 degrees Celsius. I'll let you figure out if the can would melt...

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- No, it is highly unlikely that 101 aluminum sheets can be bent without cracking or breaking.

- Q: Can the aluminum sheets be used for manufacturing power distribution systems?

- Indeed, power distribution systems can make use of aluminum sheets for their manufacturing needs. The electrical industry widely embraces aluminum as a material of choice due to its exceptional conductivity, lightweight nature, and cost-effectiveness. Notably, busbars, the essential elements within power distribution systems, are commonly crafted using aluminum. This is made possible by the ease with which aluminum sheets can be fabricated and shaped to conform to the desired busbar configuration, thereby enabling efficient transmission and distribution of power. Furthermore, aluminum displays commendable resistance to corrosion, rendering it suitable for outdoor applications. However, it remains crucial to guarantee that the aluminum sheets adhere to the required electrical and mechanical specifications for power distribution systems to ensure both their safety and reliability during operation.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: When water continually sprays on the aluminum sheet, how to avoid corrosion of aluminum sheet and keep its water resistance?

- aluminum will react with oxygen, generating dense Al2O3 oxide film on the surface, once the pure aluminum is exposed in air, it will react with air, generating oxide film to protect it.

- Q: Can the aluminum sheets be used for manufacturing solar panel frames?

- Indeed, solar panel frames can be manufactured using aluminum sheets. The solar industry frequently employs aluminum due to its lightweight nature, durability, and ability to resist corrosion. When it comes to solar panel frames, aluminum proves to be an excellent selection as it offers structural support and can endure diverse weather conditions. Moreover, aluminum is easily recyclable, thereby presenting an environmentally conscious choice for solar panel manufacturers. All in all, aluminum sheets are a fitting material for the production of solar panel frames.

Send your message to us

5086 Aluminum Sheets - Polyester Coated Aluminum Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords