430 Stainless Steel Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description:

Stainless steel plate according to the method of divided into two kinds of hot rolling and cold rolling, including 0.5-4 mm thickness plates and 4.5-35 mm thick plate, according to the characteristics of the steel group is divided into 5 classes: Austenitic, austenitic iron body, iron body, martensitic, precipitation hardening type. Can withstand the corrosion of oxalic acid, sulfuric acid and ferric sulfate, nitric acid, nitric acid and hydrofluoric acid, copper sulfate sulfuric acid, phosphoric acid, formic acid, acetic acid, etc. all kinds of acid, widely used in chemical, food, medicine, paper making, petroleum, nuclear energy and other industries, as well as the construction, kitchen utensils, cutlery, vehicles, household appliances, all kinds of spare parts requirements. In order to ensure that each kind of stainless steel plate of the yield strength, tensile strength, elongation and hardness of mechanical properties to meet the requirements, the plate before delivery must be after annealing, solid solution treatment, aging treatment of heat treatment. The corrosion resistance of the stainless steel mainly depends on its alloy composition (chrome, nickel, titanium, silicon, aluminum, etc.) and internal structure, the main role is chromium element. Chromium has a high chemical stability, can form a passivation film on the steel surface, so that the metal and the outside world to isolate, protect the steel plate is not oxidized, increase the corrosion resistance of the steel. When the passivation film is destroyed, the corrosion resistance decreases.

2.Product characteristic:

430 stainless steel plate has all the characteristics of 430 stainless steel, has good resistance to corrosion and general steel, better thermal conductivity than austenite, thermal expansion coefficient smaller than the austenitic, thermal fatigue, add stabilizing elements in titanium, good weld mechanical properties, mainly for building decoration, the parts of a fuel burner, home appliances and home appliance components.

3.Parameter:

430 stainless steel has the following several States, the state is not the same, the stain resistance and corrosion resistance are not the same.

NO.1, 1D, 2D, 2B, N0.4, HL, BA, Mirror, and various other surface processing states.

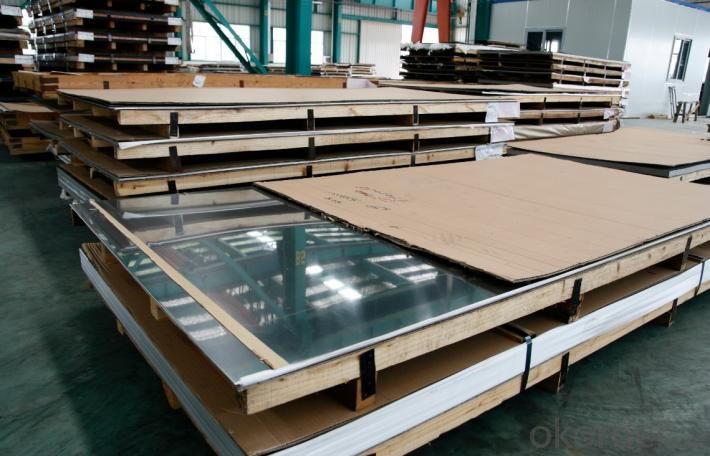

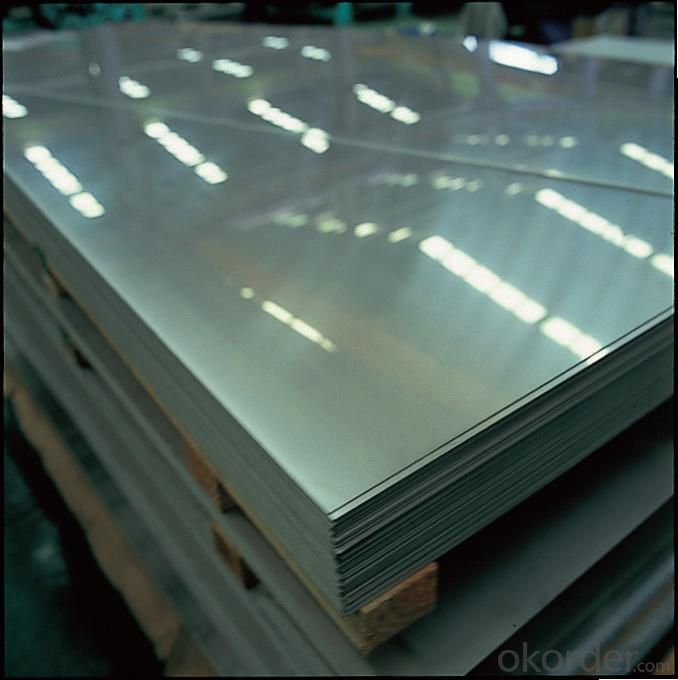

4.Reference picture:

- Q: How are steel coils priced in the market?

- Steel coils are priced in the market based on various factors such as the current demand and supply levels, raw material costs, production and transportation expenses, market competition, and overall market conditions. Additionally, quality, size, and specifications of the steel coils also play a role in determining their pricing.

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: How are steel coils priced and traded in the market?

- Steel coils are priced and traded in the market based on several factors. The primary factor is the current demand and supply dynamics of the steel industry. When the demand for steel coils is high, the prices tend to increase, and vice versa. Another important factor in pricing steel coils is the cost of raw materials, such as iron ore and coal, which are essential for steel production. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Additionally, the quality and specifications of the steel coils also play a significant role in determining their price. Higher-quality coils with specific characteristics, such as strength, corrosion resistance, or surface finish, may command a premium price in the market. The trading of steel coils is primarily done through various platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market is another avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without going through a formal exchange. This provides flexibility and customization in trading, allowing for specific requirements to be met. Overall, the pricing and trading of steel coils in the market are influenced by demand and supply dynamics, raw material costs, quality specifications, and trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: How are steel coils used in the construction of bridges?

- Steel coils are used in the construction of bridges primarily for their strength and durability. They are shaped and welded into various structural components, such as beams and girders, which provide support and stability to the bridge structure. Steel coils also serve as reinforcement in concrete structures, enhancing their load-bearing capacity. Additionally, steel coils are used for manufacturing bridge decks, guardrails, and other essential elements that contribute to the overall strength and longevity of the bridge.

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: How are steel coils used in the production of steel containers?

- Steel coils are used in the production of steel containers by being processed and shaped into the desired form. These coils are unrolled and cut into specific lengths, which are then formed into the shape of the container. The coils provide the necessary material and strength to create durable and sturdy containers for various industries such as shipping, storage, and manufacturing.

- Q: How are steel coils processed before they are used in manufacturing?

- Steel coils are processed before they are used in manufacturing through a series of steps including cleaning, pickling, cold rolling, annealing, and coating. These processes remove impurities, improve surface quality, reduce thickness, enhance mechanical properties, and provide corrosion resistance to ensure that the steel coils meet the required specifications for various manufacturing applications.

- Q: Hi all.I'm working on a project which requires about 3 steel pipes at 25mm in diametre and about a foot each in length.The qualities I need with the steel is that:1. I need it to be easy enough to weld together2. I need to be able to drill holes through them with a basic drill (I could buy different bits, that's fine)3. I need the steel to be able to take short intense repeated bursts of strain through said holes4. The lighter the steel the better5. Could I please have a ballpark figure for price. I can't imagine such a small amount of steel would cost too muchThank you in advance for your replyRegardsSean

- I do not understand what is meant by, ...repeated bursts of strain through said holes, but I would think that standard a pipe for home plumbing would do. In my vicinity, and I practice own home plumbing, I buy a whole pipe 6 meters long for about the equivalent of $(20-15). A local plumber might give you the short pieces you after for free.

- Q: How are steel coils used in the manufacturing of steering columns?

- Steel coils are used in the manufacturing of steering columns as they provide strength and durability to the structure. The steel coils are typically formed into a cylindrical shape and then welded or joined together to create the main body of the steering column. This ensures that the steering column can withstand the forces and impacts experienced during vehicle operation, providing stability and control to the driver.

- Q: How are steel coils used in the manufacturing of chassis frames?

- Steel coils are used in the manufacturing of chassis frames by being processed and formed into specific shapes and dimensions. The coils are first uncoiled and then passed through various machines to cut, bend, and weld them into the desired frame structure. This process ensures that the chassis frame is strong, durable, and able to withstand the demands of a vehicle's weight and functionality.

Send your message to us

430 Stainless Steel Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords