Stainless Steel Sheet/Plate 420 for Surgery

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 420 for Surgery

Description of Stainless Steel Sheet/Plate 420 for Surgery:

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widelyused in light industry,heavy industry,daily necessities and the decoration industry.my company long-termsupply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Main Features of Stainless Steel Sheet/Plate 420 for Surgery:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Application of Stainless Steel Sheet/Plate 420 for Surgery:

Stainless steel’s resistance to corrosion and staining, low maintenance and familiar lustre make it an ideal material for many application

s.There are over 150 grades of stainless steel, of which fifteen are most commonly used. The alloy is milled into coils, sheets, plates,

bars, wire, and tubing to be used in cookware, cutlery, household hardware, surgical instruments, major appliances, industrial equipme

nt Storage tanks and tankers used to transport orange juice and other food are often made of stainless steel, because of its corrosion re

sistance and antibacterial properties. This also influences its use in commercial kitchens and food processing plants, as it can be steam

cleaned and sterilized and does not need paint or other surface finishes..

Specifications of Stainless Steel Sheet/Plate 420 for Surgery:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 420 for Surgery:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

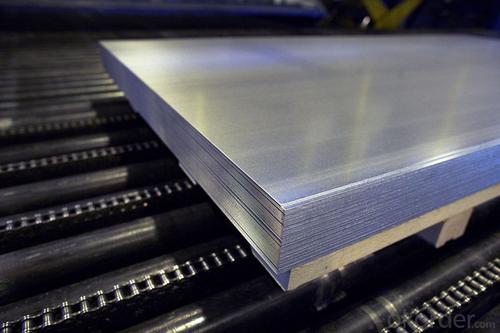

Images of Stainless Steel Sheet/Plate 420 for Surgery:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 420 for Surgery:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Can stainless steel sheets be used for wall cladding?

- Certainly! Wall cladding can indeed utilize stainless steel sheets. This material, known for its durability and resistance to corrosion, proves to be a fitting selection for cladding purposes. Its sleek and contemporary appearance enhances the aesthetic appeal of walls. Furthermore, stainless steel sheets are effortless to install and maintain, rendering them an exceptional choice for both indoor and outdoor walls. Moreover, they possess remarkable fire resistance and can endure high temperatures, guaranteeing a secure option for wall cladding.

- Q: What are the different types of surface protection available for stainless steel sheets?

- There are various options available for protecting stainless steel sheets from corrosion, scratches, and other damage. Each option offers different levels of protection and can be chosen based on specific needs. One commonly used method is the application of a thin, adhesive film onto the stainless steel surface. This film acts as a barrier, safeguarding the sheet from scratches, dirt, and other contaminants. Typically, this film is removed after the sheet is installed. Another popular option is PVC coating, which involves applying a thicker and more durable layer of polyvinyl chloride onto the stainless steel. This coating provides excellent corrosion resistance and is available in different colors and finishes. It can be applied through a process called powder coating. Alternatively, a layer of paint can be applied to the stainless steel surface through spray painting or electrostatic coating methods. Paint coatings not only protect against corrosion but also enhance the appearance of the sheet. Passivation is a chemical process that removes iron from the stainless steel surface, creating a protective oxide layer. This layer improves the sheet's resistance to corrosion and is commonly used in industries with aggressive environments. Electropolishing is a process that removes a thin layer of metal from the stainless steel surface, resulting in a smooth and clean finish. It not only enhances the appearance but also increases the sheet's corrosion resistance. Metal plating involves applying a thin layer of another metal, such as zinc or nickel, onto the stainless steel surface. This provides sacrificial protection, as the plated metal corrodes instead of the underlying stainless steel. Metal plating is commonly used in outdoor applications exposed to harsh environments. When selecting the appropriate surface protection method, it is crucial to consider factors such as the environment, intended use, and aesthetic preferences. These factors will help determine the most suitable option for protecting the stainless steel sheet.

- Q: What are the standard sizes of stainless steel sheets?

- The specific industry and application dictate the varying standard sizes of stainless steel sheets. Nevertheless, there exist some widely accessible commonly used standard sizes. In the architectural and construction sector, stainless steel sheets usually come in sizes ranging from 4 feet by 8 feet (1220mm x 2440mm) to 5 feet by 10 feet (1524mm x 3048mm). These dimensions find common use in cladding, roofing, and interior design applications. In the manufacturing and industrial domains, stainless steel sheets are available in diverse sizes, including 4 feet by 8 feet, 4 feet by 10 feet (1220mm x 3050mm), and even larger sizes like 5 feet by 12 feet (1524mm x 3658mm). These larger dimensions frequently serve fabrication, industrial machinery, and equipment manufacturing purposes. It is important to acknowledge that custom sizes can also be produced according to specific project requirements. These custom sizes may encompass narrower or wider widths, longer or shorter lengths, or even different thicknesses to cater to a particular application's needs. Ultimately, industry standards, market demand, and manufacturer capabilities determine the standard sizes of stainless steel sheets. It is advisable to consult suppliers or manufacturers to verify the availability of the desired size before making a purchase.

- Q: Can stainless steel sheets be used for countertops?

- Yes, stainless steel sheets can be used for countertops. Stainless steel is a durable and versatile material that is resistant to stains, heat, and bacteria, making it an excellent choice for kitchen countertops. It is easy to clean, maintain, and has a sleek and modern appearance. Stainless steel countertops are commonly used in commercial kitchens but are also becoming increasingly popular in residential settings due to their durability and hygienic properties.

- Q: Seeking stainless steel plate 304 material and 304j material what is the difference?

- 304J1 is a kind of material in stainless steel plate. Is 304 of copper containing material, deep drawing performance better than 304, mainly for deep processing purposes, but also belong to the nickel series.

- Q: Can stainless steel sheets be used for outdoor signage?

- Yes, stainless steel sheets can be used for outdoor signage. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions and maintain its appearance over time. It is commonly used in outdoor signage due to its ability to resist rust, fading, and damage from exposure to sunlight, rain, snow, and other environmental elements. Additionally, stainless steel sheets can be customized with various finishes, such as brushed or polished, to enhance their visual appeal and make them suitable for any outdoor signage application.

- Q: What is the difference between stainless steel sheets and stainless steel plates?

- The main difference between stainless steel sheets and stainless steel plates lies in their thickness. Stainless steel sheets are typically thinner, with a thickness ranging from 0.4mm to 6mm, while stainless steel plates are thicker, with a thickness starting from 3mm and going up to several inches. Additionally, stainless steel plates are often used for structural purposes or heavy-duty applications, while stainless steel sheets are commonly used for decorative purposes, cladding, or smaller projects.

- Q: Are stainless steel sheets suitable for laboratory equipment or instruments?

- Yes, stainless steel sheets are highly suitable for laboratory equipment and instruments. Stainless steel is known for its excellent corrosion resistance, which is crucial in laboratory environments where equipment comes into contact with various chemicals and substances. It is also highly resistant to heat, making it suitable for use with high-temperature processes or sterilization procedures. Additionally, stainless steel is easy to clean and maintain, which is essential for maintaining a sterile and hygienic laboratory environment. The durability and strength of stainless steel make it ideal for withstanding heavy usage and ensuring long-lasting performance. Overall, stainless steel sheets are a reliable and popular choice for laboratory equipment and instruments due to their corrosion resistance, heat resistance, cleanliness, and durability.

- Q: How do you prevent discoloration or staining on stainless steel sheets?

- To prevent discoloration or staining on stainless steel sheets, there are several steps one can take. First, it is important to clean the sheets regularly using mild soap or detergent and warm water. Avoid abrasive cleaners or scrub brushes that could scratch the surface. After cleaning, rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. In addition, it is crucial to avoid using harsh chemicals like bleach, ammonia, or chlorine-based cleaners on stainless steel sheets. These chemicals can cause discoloration or staining. Instead, opt for stainless steel-specific cleaners or natural alternatives such as vinegar or lemon juice. Proper storage is also essential. Stainless steel sheets should be kept in a clean and dry environment to prevent exposure to moisture or humidity. Moisture can lead to corrosion or rust, resulting in discoloration. If the sheets are stored outdoors, make sure to adequately cover them to protect against rain or snow. Applying a protective coating or sealant on stainless steel sheets can help prevent discoloration or staining. There are various products available specifically designed for stainless steel protection. It is important to follow the manufacturer's instructions for application and reapplication if necessary. Furthermore, it is important to avoid contact between stainless steel sheets and other reactive metals such as iron, copper, or aluminum. When these metals come into contact with stainless steel, a chemical reaction called galvanic corrosion can occur, leading to discoloration and staining. To prevent this, ensure separation or isolation between stainless steel and reactive metals. Regular maintenance is crucial in preserving the appearance and integrity of stainless steel sheets. Regularly inspect the sheets for any signs of discoloration, staining, or damage. Address any issues promptly to prevent further deterioration. If stubborn stains are present, use a non-abrasive stainless steel cleaner and a soft cloth to gently rub the affected area in the direction of the grain. By following these preventive measures, the appearance and integrity of stainless steel sheets can be maintained, ensuring they remain free from discoloration or staining for an extended period of time.

- Q: Are stainless steel sheets suitable for hygienic applications?

- Yes, stainless steel sheets are highly suitable for hygienic applications. Stainless steel is corrosion-resistant, non-porous, and easy to clean, making it ideal for environments that require strict hygiene standards, such as hospitals, food processing plants, and laboratories. Additionally, stainless steel has antimicrobial properties that inhibit the growth of bacteria, further enhancing its suitability for hygienic applications.

Send your message to us

Stainless Steel Sheet/Plate 420 for Surgery

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords