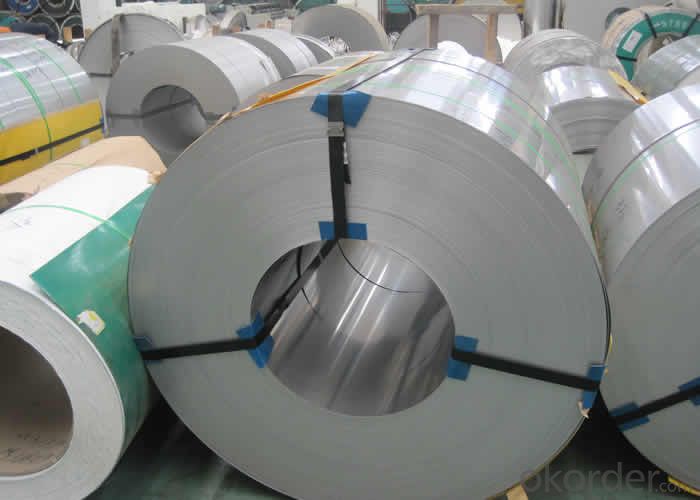

Stainless Steel Coil 304 Surface Finish No.1

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grade: | 300 Series | Standard: | JIS,AISI,ASTM,GB,DIN,EN etc | Thickness: | 2.5mm, 3.0mm, 4.0mm |

Width: | 550mm-1500mm | Length: | according to weight | Place of Origin: | China (Mainland) |

Brand Name: | CNBM | Model Number: | 304 | Technique: | Hot Rolled |

Application: | industry, construction, furniture, repairing | Certification: | MTC | Finishing: | NO.1 |

Market: | globle area | Packaged: | wooden and bags in cases as standard | Payment: | TT & LC |

Delivery time: | 15 days | MOQ: | 100 tons | Advantage: | prime quality, competitive price |

Profession: | hot rolled | Charactor: | stainless steel coils | Material/Grade: | 304 |

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

Hot Rolled Stainless Steel Coil 304 Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2m or requirement

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 |

Thickness | 3.0mm-4.0mm |

Width | 550mm, 650mm, 1000mm, 1219mm, 1240mm, 1500mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 20000 tons/month |

- Q: Can stainless steel strips be used in contact with food?

- Yes, stainless steel strips can safely be used in contact with food. Stainless steel is known for its corrosion resistance, durability, and non-reactive properties, which makes it a popular choice for food-related applications such as kitchen utensils, cookware, and food processing equipment.

- Q: Are stainless steel strips suitable for chemical storage tanks?

- Yes, stainless steel strips are suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion, making it ideal for storing various chemicals. It can withstand a wide range of temperatures and is durable, ensuring the integrity and safety of the stored chemicals.

- Q: What are the common surface finishes for stainless steel strips?

- Common surface finishes for stainless steel strips include: 1. Mill Finish: This is the basic finish that is achieved after the stainless steel strip has been hot or cold rolled. It has a dull, non-reflective appearance. 2. Brushed Finish: This finish is created by brushing the stainless steel strip with abrasive materials, resulting in a textured appearance. It helps to hide surface imperfections and gives the strip a satin-like finish. 3. Polished Finish: The stainless steel strip is mechanically polished to create a smooth, reflective surface. This finish is commonly used for decorative purposes and is available in various levels of polish, such as mirror polish or satin polish. 4. Embossed Finish: In this finish, the stainless steel strip is passed through embossing rollers that create raised or sunken patterns on the surface. It adds texture and visual interest to the strip. 5. Patterned Finish: Stainless steel strips can be patterned using various techniques, such as etching or laser engraving. This creates decorative patterns or designs on the surface, giving the strip a unique and distinctive look. 6. Coated Finish: Stainless steel strips can be coated with a thin layer of another material, such as a polymer or a metal, to enhance its appearance or provide additional protection against corrosion. These are some of the common surface finishes for stainless steel strips, each offering different aesthetics and functionality to suit various applications.

- Q: Can stainless steel strips be used in the construction industry?

- Yes, stainless steel strips are commonly used in the construction industry. They are versatile, durable, and resistant to corrosion, making them suitable for various applications such as structural support, cladding, roofing, and interior finishes.

- Q: Can stainless steel strips be used in elevator doors?

- Yes, stainless steel strips can be used in elevator doors. Stainless steel is a popular choice for elevator doors due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and modern look while also withstanding the wear and tear associated with elevator usage.

- Q: How do you prevent galling of stainless steel strips?

- There are several measures that can be taken to prevent galling of stainless steel strips: 1. Lubrication is key in reducing the risk of galling. Applying lubricants like anti-seize compounds, oils, or greases creates a protective barrier between the surfaces, minimizing friction and the likelihood of galling. 2. Ensuring a smooth surface finish on the stainless steel strips helps prevent galling. Rough or uneven surfaces increase friction, making galling more likely. Polishing or grinding the surfaces creates a smoother finish, reducing the risk of galling. 3. Material selection plays a role in preventing galling. Some grades of stainless steel have better resistance to galling. For example, austenitic stainless steels with higher nickel content, such as 304 and 316, are known for their anti-galling properties. 4. Proper tightening is crucial. Applying the correct torque when fastening stainless steel strips together is important. Over-tightening can increase the risk of galling as excessive pressure can cause the surfaces to seize. Using a torque wrench or following manufacturer guidelines for tightening can prevent galling. 5. Avoiding metal-on-metal contact is another effective measure. Using non-metallic materials like plastic or rubber washers or inserts creates a barrier between the stainless steel strips, reducing friction and the likelihood of galling. In conclusion, a combination of lubrication, surface finish, material selection, proper tightening, and avoiding metal-on-metal contact effectively prevents galling of stainless steel strips.

- Q: Can stainless steel strips be used in the petrochemical industry?

- Certainly, the petrochemical industry finds stainless steel strips to be a valuable asset. The exceptional corrosion resistance of stainless steel renders it suitable for a wide range of applications in this sector. Given that petrochemical processes often involve the manipulation of various corrosive chemicals, gases, and liquids, stainless steel strips are frequently employed in the construction of storage tanks, pipelines, heat exchangers, and other necessary equipment. The indispensability of corrosion resistance in these structures cannot be overstated. Moreover, the high strength and durability of stainless steel endow it with the ability to withstand the demanding conditions of the petrochemical industry, including high temperatures and pressures. Consequently, it is safe to conclude that stainless steel strips are the preferred material in the petrochemical sector due to their corrosion resistance, strength, and longevity.

- Q: What are the typical tolerance levels for stainless steel strips?

- The typical tolerance levels for stainless steel strips can vary depending on the specific industry and application. However, common tolerance ranges for thickness can be around +/- 0.001 to 0.005 inches, for width it can be +/- 0.010 to 0.020 inches, and for length it can be +/- 0.020 to 0.040 inches. These ranges may vary further based on the specific requirements and standards set by manufacturers and customers.

- Q: Are 111 stainless steel strips suitable for decorative applications?

- Indeed, decorative applications can indeed benefit from the suitability of 111 stainless steel strips. Renowned for its corrosion resistance, durability, and aesthetic charm, stainless steel has gained popularity in the realm of decorative purposes. The utilization of grade 111 stainless steel is prevalent in architectural and interior design ventures, including wall cladding, signage, furniture, and decorative trims. Its sleek and contemporary appearance, with a smooth and reflective surface, can effortlessly enhance any given area. Furthermore, the practicality of stainless steel is evident through its easy cleaning and maintenance, rendering it an ideal choice for decorative applications in both residential and commercial settings.

- Q: What is the typical thickness range for stainless steel strips?

- The typical thickness range for stainless steel strips can vary, but it is generally between 0.015 inches (0.38 mm) to 0.1875 inches (4.76 mm).

Send your message to us

Stainless Steel Coil 304 Surface Finish No.1

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords