4 X 8 Aluminum Sheets - Aluminum Sheet Manufacturer, Price, Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

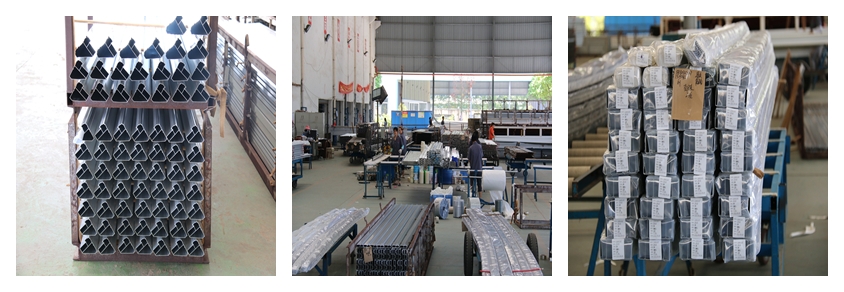

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: What is the surface finish of 101 aluminum sheets?

- The surface finish of 101 aluminum sheets can vary depending on the specific manufacturing process and desired application. However, common surface finishes for 101 aluminum sheets include mill finish, brushed finish, anodized finish, and painted finish. Mill finish refers to the raw, untreated surface of the aluminum sheet, which may have some minor imperfections or scratches. Brushed finish is achieved by brushing the surface of the sheet with a fine abrasive material, resulting in a smooth, satin-like appearance. Anodized finish involves an electrochemical process that forms a protective oxide layer on the surface of the aluminum, providing enhanced durability and corrosion resistance. Painted finish, on the other hand, involves applying a layer of paint onto the aluminum sheet to provide color and additional protection. Ultimately, the choice of surface finish for 101 aluminum sheets depends on the desired aesthetic, functional, and environmental requirements of the application.

- Q: What are aluminum sheets used for?

- Aluminum sheets have a wide range of uses due to their unique properties and versatility. One of the most common applications is in construction, where aluminum sheets are used for roofing, siding, and cladding. Their lightweight nature, corrosion resistance, and durability make them ideal for these purposes. Aluminum sheets are also widely used in the transportation industry. They are commonly utilized in the manufacturing of automobiles, trains, and aircraft due to their high strength-to-weight ratio. Additionally, aluminum sheets are utilized in the production of trailers, truck bodies, and shipping containers, as they provide a lightweight yet sturdy solution. Another important application of aluminum sheets is in the manufacturing of consumer products. They are used for making household appliances, cookware, and electronics due to their excellent thermal conductivity and resistance to rust and corrosion. Aluminum sheets are also employed in the production of signage, billboards, and displays due to their ability to withstand various weather conditions. In the packaging industry, aluminum sheets play a crucial role. They are commonly used for making cans, foils, and lids due to their impermeability to light, moisture, and oxygen. Aluminum sheets help preserve the freshness and quality of food and beverages. Furthermore, aluminum sheets have various industrial applications. They are utilized in the fabrication of industrial machinery, equipment, and tools due to their excellent machinability and strength. Aluminum sheets are also used in the production of heat exchangers, solar panels, and electrical conductors due to their thermal and electrical conductivity. In summary, aluminum sheets are utilized in construction, transportation, consumer products, packaging, and various industrial applications due to their lightweight, corrosion resistance, durability, thermal conductivity, and electrical conductivity.

- Q: Are aluminum sheets suitable for soundproofing applications?

- Yes, aluminum sheets can be suitable for soundproofing applications. Aluminum has good sound-blocking properties and can help reduce noise transmission when used in soundproofing applications. It is a lightweight material that can be easily installed as barriers or panels to create a sound barrier between different areas or to isolate specific equipment or machinery. Additionally, aluminum sheets can be used in combination with other soundproofing materials, such as foam or rubber, to enhance their soundproofing capabilities. However, it is important to note that the thickness and density of the aluminum sheets will play a significant role in determining their effectiveness for soundproofing. Thicker and denser aluminum sheets will provide better sound insulation compared to thinner ones. Additionally, other factors such as the design, construction, and installation of the soundproofing system will also impact its overall effectiveness in reducing noise.

- Q: What are the different methods for finishing the edges of aluminum sheets?

- Depending on the desired outcome and application, there are several approaches to finishing the edges of aluminum sheets. One commonly used method is edge trimming, where excess material is removed from the sheet's edges to achieve a smooth and straight edge. This can be accomplished using various tools like shears, saws, or routers. Another technique is edge deburring, which is employed to eliminate any sharp or rough edges left after cutting. Sanding or grinding tools are often utilized to smooth out the edges and produce a more polished finish. Moreover, edge rolling is a method that can be employed to create rolled or rounded edges on aluminum sheets. This is achieved by using a rolling machine that applies pressure to the edges, bending them into the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to craft custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option worth considering. This process entails applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps protect the edges from corrosion or other damage. Ultimately, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific project requirements.

- Q: I'm thinking of starting raised beds for a vegetable garden. I'm thinking about a shallow aluminum stock tank, about 12 in. deep x 4 ft. long. Having limited sunlight available, these could be moved around the yard and tended to easily. Any ideas? Aluminum with soil? Any effects? Holes will be drilled in the bottom for drainage. Thanks!

- You okorder it's just the site your looking for vers exactly what your doing,or want to do.

- Q: This question asks for guidance on selecting a trustworthy supplier for purchasing aluminum sheets.

- <p>To choose a reliable supplier of aluminum sheets, consider the following: Check their reputation by reading reviews and testimonials. Ensure they have a valid certification and adhere to industry standards. Evaluate their product quality by requesting samples or visiting their production site. Assess their delivery times and reliability. Confirm they offer competitive pricing without compromising on quality. Look for suppliers with good customer service and after-sales support. Finally, consider their financial stability and ability to fulfill large orders.</p>

- Q: I heard somewhere that when aluminum is heated, it releases something that is a known cause of Alzheimers. Is this true? I have a homemade cooker made of aluminum and I don't want Alzheimers.

- They felt that used to be the case because of the aluminum seeping into the food. Hard to find an uncoated aluminum pot now. You get more aluminum from deodorants and antacids than cookware. You shouldn't though cook or store tomatoes in aluminum...and that's just the reaction in chemistry.

- Q: Are aluminum sheets suitable for architectural canopies?

- Yes, aluminum sheets are suitable for architectural canopies. Aluminum is a popular choice for architectural applications due to its lightweight nature, durability, and flexibility. It offers high strength-to-weight ratio, making it capable of withstanding various weather conditions and providing stability for canopies. Additionally, aluminum is highly resistant to corrosion, ensuring that the architectural canopy remains visually appealing and functional for a long time. Its malleability allows for easy fabrication and customization, enabling architects and designers to create unique and intricate canopy designs. Furthermore, aluminum is a sustainable material as it can be recycled, contributing to environmentally friendly construction practices. Overall, aluminum sheets are a reliable and versatile option for architectural canopies.

- Q: Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- The best polish I have found is BlingMaster Aluminator. Brought back my wheels to look like Brand New.

Send your message to us

4 X 8 Aluminum Sheets - Aluminum Sheet Manufacturer, Price, Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords