316 Stainless Steel Plate price per kg in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

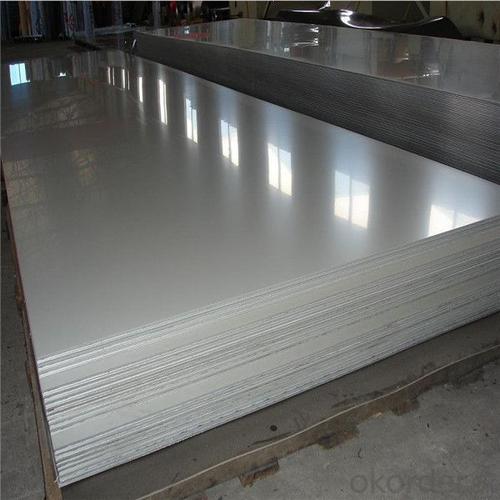

316 stainless steel plate price per kg

Product Description

Item Type | 316 Stainless Steel Plate price per kg |

Material | 201, 304, 410,430, 316 stainless steel coils & sheets & strip |

Standard | ASTM240 AISI GB DIN JIN |

Thickness | 0.15mm-4.0mm or Customized |

Specification | 1m*2m . 4ft*8ft. 4ft*10ft or Customized |

Width | 1000mm, 1219mm or Customized |

Length | 2000mm, 2438mm, 3048mm or Customized |

Surface Polishing | No.1, 2B, BA, Mirror, 8K,10K, BA, Brushed,No.4, Hairline, Grit: #180 #240 #280,#320 |

Surface Finishing | Etched, Embossed, PVD Colored, Perforated, Chequered, Polished |

Color | Golden, Black Golden, Champagne Gold, Rose Golden, Dusk, Azure, Sapphire, Bronze, Antique Brass, Bronze, Wine Red, Chinese red, Rose red, Tawny, Violet, etc |

Test | Eddy current/hydrostatic, mechanical, chemical composition analysis. |

Packaging | Wooden Box, Steel Box, Standard Seaworthy |

Application | Art Decoration, Partition Screen, Door, Lift Decoration, Wall Decoration, Cover Panel, Table top, and or decorative surface. Used in construction, chemical industry, electricity industry, food service industry, paper-making industry, and so on. |

Delivery time | 15-35 days after order confirmed |

Payment terms | T/T, L/C, D/A, D/P |

Chemical Composition

Chemical Composition | ||||

SS304 | SS 316 | SS430 | SS201 | |

Ni(%) | 8.0-10.5 | 10.0-14.0 | -- | 0.8-1.2 |

Cr(%) | 18.0-20 | 16.0-18.0 | 16.0-18.0 | ≤0.15 |

C(%) | ≤0.08 | ≤0.08 | ≤0.12% | ≥40 |

Elong(%) | ≥40 | ≥40 | ≥22 | |

Hardness | HB≤187,HRB≤90, HV≤200 | HB≤187, HRB≤90 HV≤200 | HB≤183, HRB≤88 HV≤200 | HB≤241,HRB≤100, HV≤240 |

Product Uses

1.Automotive:

Automotive trim and molding /Exhaust-system components, tubular manifolds, mufflers / Catalytic converter shells

2.Construction:

Gutters and downspouts, roofing, siding

3.Kitchenware:

Cooking utensils, dishwashers, ovens, range hoods, refrigerators

4.Chemical processing:

Oil refinery equipment, oil burner and heater parts

5.Appliances:

Hot water tanks, residential furnaces, escalator, doors

6.Power generation:

Heat Exchanger tubing

Packaging & Shipping

1.Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

2.Shipping: Ocean transportation,land transportation or air transportation.

- Q: Can stainless steel sheets be used for decorative room dividers or partitions?

- Yes, stainless steel sheets can definitely be used for decorative room dividers or partitions. Stainless steel is a versatile material that offers a sleek and modern look, making it a popular choice for contemporary interior designs. Its durability and resistance to corrosion also make it suitable for long-term use in various settings, including homes, offices, or commercial spaces. Additionally, stainless steel sheets can be customized with different finishes, patterns, or perforations to enhance their decorative appeal and create unique room dividers or partitions.

- Q: What are stainless steel sheets made of?

- Stainless steel sheets are primarily made of iron alloyed with chromium and other elements like nickel, molybdenum, and manganese to enhance their corrosion resistance and durability.

- Q: Stainless steel plate glued to tiles, what glue?

- 4. determine the amount of adhesive used for the first product, and then determine the maximum cost of the glue used in this product.5., then you can accurately know and choose the right for their own glue.

- Q: Can stainless steel sheets be used in high-temperature applications?

- Yes, stainless steel sheets can be used in high-temperature applications. Stainless steel has excellent heat resistance properties, making it suitable for use in environments with elevated temperatures. Its high melting point and ability to resist oxidation and scaling at high temperatures make it a popular choice for applications such as aerospace, automotive, and industrial processes that involve exposure to heat.

- Q: How do you prevent galling on stainless steel sheets?

- To prevent galling on stainless steel sheets, it is important to use lubricants or anti-seize compounds during the manufacturing or assembly process. This helps reduce friction and surface adhesion, minimizing the risk of galling. Additionally, using proper cutting tools and techniques, such as slow speeds and low feed rates, can also help prevent galling.

- Q: Can stainless steel sheets be used for magnetic shielding?

- To a certain extent, stainless steel sheets can be utilized for magnetic shielding. Although stainless steel is not intrinsically magnetic, it possesses some magnetic properties due to the presence of iron, a magnetic material, in stainless steel alloys. This enables stainless steel sheets to exhibit weak magnetic characteristics. Nevertheless, the magnetic shielding capabilities of stainless steel sheets are limited when compared to materials specifically engineered for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more efficiently than stainless steel. However, stainless steel sheets can still offer some level of magnetic shielding, particularly in environments with lower intensity magnetic fields. They can assist in reducing the transmission of magnetic fields from one area to another, which can be beneficial in certain applications. Nonetheless, for situations that require high-intensity or sensitive magnetic shielding, it is recommended to utilize specialized magnetic shielding materials for optimal effectiveness.

- Q: Are stainless steel sheets suitable for outdoor railings?

- Indeed, outdoor railings can be made from stainless steel sheets. Renowned for their resistance to corrosion and remarkable durability, stainless steel sheets are a favored selection for outdoor purposes. Furthermore, they possess the ability to endure adverse weather conditions, such as rain, snow, and UV radiation, without compromising their structural integrity or visual appeal. As a result, stainless steel railings require minimal maintenance and are effortlessly cleaned, rendering them a practical and enduring choice for outdoor areas. In addition to their practicality, stainless steel sheets provide a sleek and contemporary aesthetic, elevating the overall appearance and ambiance of any outdoor railing system.

- Q: What brand of stainless steel plate is good?

- It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

- Q: What are the benefits of using perforated stainless steel sheets?

- Perforated stainless steel sheets offer several benefits. Firstly, they provide excellent ventilation and airflow, making them ideal for applications where aeration is crucial, such as in HVAC systems or industrial structures. Secondly, the perforations allow for enhanced visibility, enabling the passage of light and maintaining a clear line of sight. Additionally, the perforations can aid in noise reduction by absorbing sound waves. Lastly, stainless steel sheets are highly durable, corrosion-resistant, and easy to maintain, making them a cost-effective solution for various industries.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Certainly, decorative lighting fixtures can indeed utilize stainless steel sheets. Stainless steel, being a versatile and durable material, can be molded and shaped into numerous designs and patterns, thereby making it perfect for crafting exceptional and attention-grabbing lighting fixtures. Its smooth and contemporary look adds a touch of sophistication to any area, rendering it a favored option for decorative objectives. Moreover, stainless steel's resistance to corrosion and heat guarantees that the lighting fixtures will maintain their excellent condition for an extended period.

Send your message to us

316 Stainless Steel Plate price per kg in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords