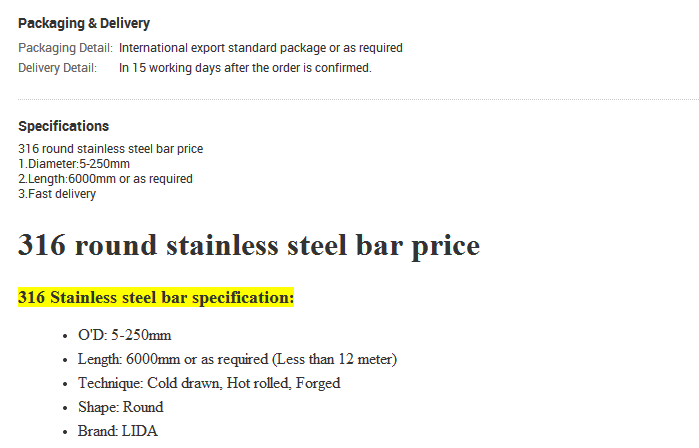

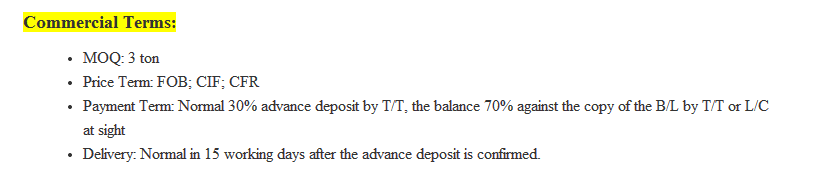

316 round stainless steel bar price for china manufacture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for automotive exhaust systems?

- Yes, stainless steel pipes are suitable for automotive exhaust systems. Stainless steel is a popular choice for exhaust systems due to its excellent resistance to corrosion and high temperatures. It can withstand the harsh conditions of an exhaust system, including exposure to moisture, heat, and chemicals. Stainless steel pipes also have good strength and durability, ensuring they can withstand the vibrations and pressure fluctuations within the exhaust system. Additionally, stainless steel pipes are known for their aesthetic appeal and can enhance the overall look of the vehicle. Overall, stainless steel pipes are a reliable and long-lasting option for automotive exhaust systems.

- Q: Can stainless steel pipes be used for chemical pumps?

- Indeed, chemical pumps can utilize stainless steel pipes. Renowned for its corrosion resistance, stainless steel proves to be an appropriate substance for managing diverse chemicals. Its ability to endure the corrosive properties of numerous chemicals safeguards against contamination of the fluids being pumped. Furthermore, stainless steel pipes provide commendable mechanical strength and endurance, rendering them suitable for chemical pumps that necessitate reliability and sustained effectiveness. Nonetheless, it is crucial to take into account the precise demands of the chemicals being pumped and seek guidance from specialists or manufacturers to guarantee the compatibility of the chosen stainless steel with the specific chemicals and operational circumstances.

- Q: Can stainless steel pipes be used for brewery and beverage industry applications?

- Yes, stainless steel pipes can be used for brewery and beverage industry applications. Stainless steel is widely recognized for its excellent corrosion resistance and hygienic properties, making it an ideal material choice for these industries. The high levels of chromium and nickel present in stainless steel pipes provide superior resistance to corrosion from chemicals, acids, and high-temperature environments. Additionally, stainless steel pipes are easy to clean and maintain, ensuring the highest level of hygiene required in brewery and beverage production. The smooth internal surface of stainless steel pipes also minimizes the risk of contamination and bacterial growth, further enhancing its suitability for these applications. Overall, stainless steel pipes offer durability, reliability, and sanitary features that make them a preferred choice for use in the brewery and beverage industry.

- Q: Can stainless steel pipes be used for paper and pulp industry applications?

- Yes, stainless steel pipes can be used for paper and pulp industry applications. Stainless steel is resistant to corrosion, chemicals, and high temperatures, making it ideal for handling corrosive liquids and chemicals used in the paper and pulp industry. Additionally, stainless steel pipes provide excellent strength and durability, ensuring long-lasting performance in demanding industrial environments.

- Q: Can stainless steel water pipes be cooled and bent?

- They are lighter in bending and torsional strength, and therefore are widely used in the manufacture of mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: How do stainless steel pipes compare to aluminum pipes?

- Stainless steel pipes and aluminum pipes have their own unique properties and advantages, making them suitable for different applications. One major difference between stainless steel pipes and aluminum pipes is their corrosion resistance. Stainless steel pipes are known for their exceptional corrosion resistance, which makes them ideal for applications where the pipes come into contact with corrosive substances such as chemicals or saltwater. On the other hand, aluminum pipes are not as resistant to corrosion as stainless steel and are more prone to oxidation. However, aluminum pipes can be made more corrosion-resistant through various coatings or treatments. Another important factor to consider is the strength and durability of the pipes. Stainless steel pipes are generally stronger and more durable than aluminum pipes. They can withstand higher pressure and temperature, making them suitable for high-stress applications such as industrial piping systems or transportation of fluids and gases. Aluminum pipes, although less strong than stainless steel, are lightweight and offer good strength-to-weight ratios, making them suitable for applications where weight is a concern, such as aerospace or automotive industries. Cost is another aspect to compare. Stainless steel pipes are usually more expensive than aluminum pipes due to the higher cost of raw materials and manufacturing processes. However, stainless steel pipes have a longer lifespan and require less maintenance, which can offset the initial higher cost in the long run. Aluminum pipes are generally more affordable, but they may require more frequent maintenance and replacement due to their lower resistance to corrosion and wear. In terms of appearance, stainless steel pipes have a sleek and polished look, while aluminum pipes can be either anodized or painted to achieve different finishes. The choice between the two would depend on the aesthetic preferences of the specific application. In summary, stainless steel pipes offer superior corrosion resistance, strength, and durability, making them suitable for demanding applications. Aluminum pipes, on the other hand, are lightweight and cost-effective, making them a preferred choice in industries where weight is a concern. Ultimately, the choice between stainless steel pipes and aluminum pipes depends on the specific requirements of the application, taking into account factors such as corrosion resistance, strength, cost, and aesthetics.

- Q: Can stainless steel pipes be used in the construction industry?

- Yes, stainless steel pipes can be used in the construction industry. They are highly durable, corrosion-resistant, and can withstand extreme temperatures, making them suitable for a wide range of applications such as plumbing, heating, ventilation, and structural support.

- Q: What is the maximum pressure rating for stainless steel pipes?

- The maximum pressure rating for stainless steel pipes can vary depending on several factors such as the grade of stainless steel, the diameter and wall thickness of the pipe, and the specific application or industry requirements. However, stainless steel pipes are known for their high strength and corrosion resistance, making them suitable for high-pressure applications. In general, stainless steel pipes can have maximum pressure ratings ranging from a few hundred psi (pounds per square inch) to several thousand psi. It is crucial to consult the appropriate industry standards, codes, and specifications or consult with a qualified engineer or manufacturer to determine the specific maximum pressure rating for a particular stainless steel pipe in a given application.

- Q: Can stainless steel pipes be insulated with polyimide?

- Yes, stainless steel pipes can be insulated with polyimide. Polyimide is a type of high-performance insulation material that is widely used in various industries for its excellent thermal stability, electrical insulation properties, and resistance to chemicals. It can withstand high temperatures and is known for its low thermal conductivity. This makes it an ideal choice for insulating stainless steel pipes, especially in applications where heat resistance and energy conservation are important. Polyimide insulation can help reduce heat transfer, prevent condensation, and improve the overall efficiency and performance of stainless steel pipes.

- Q: What are the different grades of stainless steel used for pipes?

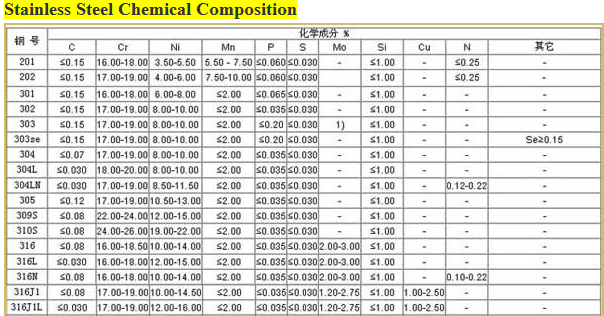

- There are several different grades of stainless steel that are commonly used for pipes, each with their own unique properties and characteristics. The most common grades include: 1. Grade 304: This is the most widely used stainless steel grade for pipes. It offers excellent corrosion resistance, high-temperature strength, and good formability. It is commonly used for both indoor and outdoor applications, such as water supply pipes, food processing equipment, and architectural structures. 2. Grade 316: This grade is similar to 304 but contains a higher content of molybdenum, which enhances its corrosion resistance, especially against chlorides and other corrosive chemicals. It is commonly used in marine environments, chemical processing plants, and medical equipment. 3. Grade 321: This grade contains titanium, which stabilizes it against sensitization during welding or high-temperature exposure. It offers excellent resistance to oxidation and can be used in applications where high temperatures are involved, such as exhaust systems and boilers. 4. Grade 409: This grade is commonly used for pipes in automotive exhaust systems due to its excellent heat resistance and durability. It is also resistant to corrosion from road salts and other harsh chemicals. 5. Grade 347: Similar to grade 321, this grade contains niobium, which provides additional stabilization against sensitization. It is commonly used in high-temperature applications where resistance to intergranular corrosion is required, such as in aircraft and jet engine components. These are just a few examples of the different grades of stainless steel used for pipes. The specific grade chosen for a particular application depends on factors such as the environment, temperature, corrosion resistance requirements, and mechanical properties needed.

Send your message to us

316 round stainless steel bar price for china manufacture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords