304 Stainless Steel Seamless Pipe Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

316 stainless steel pipe

Product Details | |

♦ Introduction | |

Stainless steel pipes, used outside, inside for decoration, construction, grade 201 202 301 304 | |

♦ Specifications | |

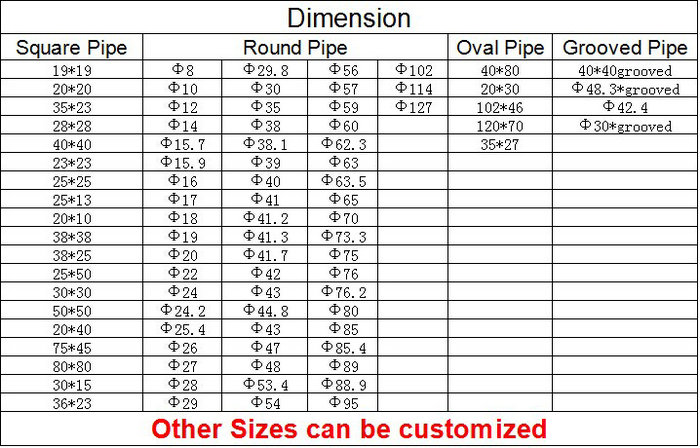

Round pipes - Outside diameter(mm) | |

8, 9.5, 11, 12, 12.7, 14.5, 15.9, 17, 18, 19, 20, 22, 23, 28, 29, 31.8 , 35, 36, 38, 45, 47, 48, 50.8, 60, 63, 76, 88.9, 102, 114, 133, 141, 159, 219 | |

Square pipes - Outside dimensions(mm) | |

10x10, 12x12, 15x15, 17x17, 18x18, 19x19, 20x20, 22x22, 23x23, 24x24, 25x25, 28x28, 30x30, 36x36, 38x38, 40x40, 48x48, 50x50, 60x60, 70x70, 80x80 | |

Rectangular pipes - Outside dimensions(mm) | |

20x10, 23x11, 24x12, 25x13, 28x13, 30x15, 34x22, 36x23, 37x24, 38x25, 40x20, 48x23, 50x15, 50x25, 60x15, 60x30, 73x43, 75x45, 95x45 | |

Wall Thickness | 0.3 - 3.0mm |

Length | 6m (or according to customers' requests) |

Polishing | 600#, 400#, 320#, 240#, 180#.etc. |

Tolerance | 1. Outer diameter: ±0.15mm 2. Thickness: ±10% of wall thickness |

Customized | Other size can be manufactured according to requirements |

Standard | Strictly follow the ASTM A 554 and others. |

Feature | |

1. Material of stainless steel: Grade: AISI 201, 202, 301,304, 304L, 316, 441, 409, 439M, 321, 430, 436L, etc. construction upholstery, and industry instruments (fencing, railing,safe doors / windows, gate fittings, inside staircases, balcony balustrades,furniture, sanitary wares, kitchen wares) | |

Implementation of Standards | |

1. GB in China; | |

Surface Type Processing | |

1. Surface polishing SB500#; | |

Products Show | |

| |

Mechanical Properties: MaterialY.S(N/MM2)T.S(N/MM2)ElongationHRB304>205>520>40<95304l>175>480>40<90316>205>520>40<90316l>175>480>40<90430>205>450>22<89

Applications: SurfaceApplication2BMedical equipment, Food industry, Construction material, Kitchen utensils.BAKitchen utensils, Electric equipment, Building construction.No.1Chemical tank, pipe.No.4Kitchen utensils, Building construction,Medical equipment.HLBuilding Construction.

|

| ---Packing & Transport--- Packing

Transport

|

- Q: Can stainless steel pipes be stress relieved?

- Yes, stainless steel pipes can be stress relieved. Stress relieving is a heat treatment process used to reduce stress-induced distortion and improve the mechanical properties of the material. Stainless steel pipes can undergo stress relieving at high temperatures, typically between 900°C and 1050°C (1652°F and 1922°F), followed by slow cooling. This process helps to relieve residual stresses that may have been induced during manufacturing processes such as welding or forming. Stress relieving can also enhance the corrosion resistance and improve the overall performance of stainless steel pipes.

- Q: Are stainless steel pipes suitable for architectural applications?

- Yes, stainless steel pipes are suitable for architectural applications. Stainless steel is a highly durable and corrosion-resistant material that can withstand harsh environmental conditions, making it ideal for architectural projects. It is commonly used in structural applications such as handrails, guardrails, and balustrades due to its strength and aesthetic appeal. Stainless steel pipes are also favored for their versatility, as they can be easily shaped and welded to create unique designs and structures. Additionally, stainless steel pipes offer low maintenance requirements and can be polished to a high shine, enhancing the overall aesthetics of architectural projects. Overall, stainless steel pipes are an excellent choice for architectural applications due to their durability, corrosion resistance, versatility, and aesthetic appeal.

- Q: The difference between stainless steel pipe and stainless steel composite pipe

- Stainless steel pipe is a kind of hollow long strip round steel, mainly used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts. In addition, the bending and torsional strength of the same weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: How do you prevent vibration in stainless steel pipes?

- To prevent vibration in stainless steel pipes, various measures can be taken: 1. Employ suitable pipe supports: It is imperative to carefully select and install appropriate pipe supports. These supports should be designed to offer ample stability and rigidity to the pipe system, minimizing any potential movement or vibration. 2. Mitigate vibrations with isolators: Strategic placement of vibration isolators along the pipe system can help absorb and dampen vibrations. This reduces the transmission of vibrations through the stainless steel pipes. 3. Ensure proper pipe alignment: During installation, ensure that the pipes are aligned correctly. Misalignment can lead to stress concentrations and heightened vibration. Proper alignment helps distribute forces evenly and reduces vibration. 4. Decrease fluid velocity: High fluid velocities can induce turbulence and vibrations in the pipe system. By reducing the fluid velocity, either through adjusting the flow rate or utilizing flow control devices like throttling valves, vibrations can be minimized. 5. Implement soundproofing measures: In certain cases, vibrations may be caused by external factors, such as nearby machinery or equipment. To reduce noise and vibrations originating from these sources, consider implementing soundproofing measures like using noise-absorbing materials or installing vibration-blocking barriers. 6. Regularly maintain and inspect the pipe system: Conduct routine inspections to detect any signs of vibration or wear in the pipe system. Address any issues promptly to prevent further vibration problems. Additionally, ensure proper maintenance of the pipe system, including regular cleaning and lubrication of any moving parts. By implementing these measures, vibration in stainless steel pipes can be effectively prevented, ensuring the overall stability and integrity of the pipe system.

- Q: Can stainless steel pipes be used for automotive applications?

- Stainless steel pipes are suitable for automotive applications, offering exceptional resistance to corrosion and heat. Because of this, they are an excellent option for automobiles in challenging environments, such as those with high temperatures, moisture, and road salt. Stainless steel pipes are frequently utilized in exhaust systems, fuel lines, and other vehicle components. Compared to other materials, they possess superior strength and durability, resulting in longer-lasting automotive parts and decreased necessity for frequent replacements. Furthermore, stainless steel pipes have a pleasing appearance and can be readily customized to meet precise design specifications for automotive use.

- Q: Why is stainless steel magnetic?

- Many customers often think that the magnet adsorption of stainless steel, to verify its merits and authenticity, and do not smoke without magnetism, that is good, genuine; smokers are magnetic, is considered a fake fake. In fact, this is a very one-sided, not practical, and the wrong way to identify, I hope the following content for your help!

- Q: Are stainless steel pipes suitable for pharmaceutical applications?

- Yes, stainless steel pipes are suitable for pharmaceutical applications. Stainless steel is a highly durable and corrosion-resistant material that is widely used in the pharmaceutical industry for various applications, including the transportation and storage of pharmaceutical products, process piping, and equipment construction. One of the main advantages of stainless steel pipes is their ability to resist corrosion, which is crucial in pharmaceutical environments where the prevention of contamination is of utmost importance. Stainless steel is resistant to a wide range of chemicals and aggressive substances, ensuring that the quality and integrity of pharmaceutical products are maintained. Furthermore, stainless steel pipes have excellent hygienic properties. They are easy to clean and sterilize, making them suitable for pharmaceutical applications that require stringent cleanliness standards. Stainless steel surfaces are smooth, non-porous, and have low levels of bacterial adhesion, making it easier to maintain a sterile environment. In addition to their corrosion resistance and hygienic properties, stainless steel pipes have high strength and durability. They can withstand high temperatures and pressures, making them suitable for various pharmaceutical processes. Stainless steel pipes also have excellent mechanical properties, such as impact resistance and fatigue strength, ensuring long-lasting performance and reducing the risk of failures in pharmaceutical applications. Overall, stainless steel pipes are widely used in the pharmaceutical industry due to their corrosion resistance, hygienic properties, and durability. They provide a reliable and safe solution for transporting and storing pharmaceutical products, as well as maintaining a clean and sterile environment.

- Q: What is the maximum length of a stainless steel pipe that can be manufactured?

- The maximum length of a stainless steel pipe that can be manufactured depends on various factors such as the manufacturing process, equipment capabilities, and logistical constraints. Generally, stainless steel pipes can be manufactured in lengths ranging from a few meters up to several hundred meters, depending on these factors.

- Q: What is the maximum diameter of stainless steel pipes available?

- The maximum diameter of stainless steel pipes can differ based on the manufacturer and supplier. Nevertheless, stainless steel pipes usually span from smaller sizes, like ½ inch or 1 inch, to larger sizes, such as 36 inches or beyond. It is crucial to acknowledge that obtaining bigger diameters might be restricted and necessitate special orders or customization. It is, therefore, recommended to consult specific manufacturers or suppliers to ascertain the maximum diameter they provide for stainless steel pipes.

- Q: What is the difference between nominal diameter and actual diameter in stainless steel pipes?

- The distinction between nominal diameter and actual diameter in stainless steel pipes is based on their respective definitions and practical applications. Nominal diameter, also referred to as nominal size, is the assigned label for a pipe based on its approximate internal diameter. It is an industry standard measurement used for communication and categorization of pipes. The nominal diameter is typically stated in inches or millimeters and is often rounded to the nearest whole number. For instance, a pipe labeled with a nominal diameter of 2 inches would generally have an internal diameter close to, but not exactly, 2 inches. On the contrary, actual diameter represents the precise measurement of the internal diameter of a stainless steel pipe. It is determined by physically measuring the inside diameter using tools such as calipers or a micrometer. The actual diameter provides an accurate measurement of the pipe's internal size, enabling precise calculations and proper fittings. The disparity between nominal diameter and actual diameter can vary depending on the manufacturing process and the specific tolerances of the stainless steel pipes. Generally, the actual diameter is slightly smaller than the nominal diameter due to factors like the thickness of the pipe's walls and manufacturing tolerances. This difference between the two measurements is known as the nominal wall thickness. Comprehending the dissimilarity between nominal diameter and actual diameter is crucial in various industries, particularly in plumbing, construction, and engineering. It ensures the appropriate selection, installation, and connection of pipes, preventing potential issues such as misalignment, leakage, or improper fittings. Therefore, it is essential to consider both the nominal diameter and actual diameter when working with stainless steel pipes to ensure the system's proper functioning and structural integrity.

Send your message to us

304 Stainless Steel Seamless Pipe Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords