3003 Aluminum Sheets for Milagros - Cold Rolling Aluminum for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Cold Rolling 3003 Aluminum for Construction Description:

Cold Rolling 3003 Aluminum for Construction are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Cold Rolling 3003 Aluminum for Construction:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

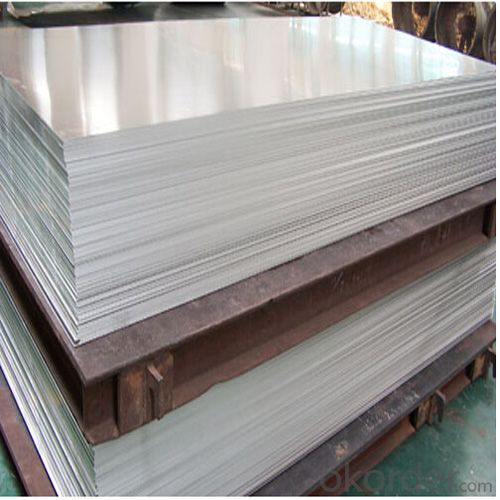

3. Cold Rolling 3003 Aluminum for Construction Images:

4. Cold Rolling 3003 Aluminum for Construction Specification:

Product | Alloy | Temper | Thickness | Width | Length | Application |

| 1050 | H18 H16 | | | | Checkered plate Curtain wall panels |

| H18 H16 | | | | ||

| H18 H16 | | | | ||

5052 | H18 H16 | 0.2~3.0 | 600~1300 | 1000~4000 |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: My professor gave us the following:1roll of Reynonlds Wrap Heavy Duty Aluminum18.0 in wide, 500.0 ft long and 0.94mil thickThe cost $48.98and I'm not sure how to figure it out

- You have : ---------------- V = aluminum volume in one roll = ( L ) ( W ) ( t ) V = ( 500 ft ) ( 1.5 ft ) ( 0.94 mil ) ( 1 in / 1000 mil ) ( 1 ft/12 in ) V = 0.05875 ft^3 m = aluminum mass = ( d ) ( V ) m = ( 168 lbm/ft^3 ) ( 0.05875 ft^3 ) = 9.87 lbm m = ( 9.87 lbm ) ( 453.6 g / 1.0 lbm ) = 4477 g n = moles of aluminum in one roll = m / M n = ( 4477 g ) / ( 27 g/mol ) = 165.8 moles Al N Al atoms = ( n Al ) ( NAVO ) N Al atoms = ( 165.8 mol ) ( 6.022 x 10^23 atoms / mol ) N Al atoms = 998.5 x 10^23 Al atoms C* = cost per atom = cost of aluminum roll / number of aluminum atoms in one roll C* = ( 4898 cents ) / 998.5 x 10^23 atoms ) C* = 4.91 x 10^-23 cents per Al atom --------------- Please award Best Answer to the most correct and most helpful response to your question. C* =

- Q: How do I choose the right thickness for my aluminum sheet?

- When choosing the right thickness for your aluminum sheet, there are several factors you should consider. Firstly, you need to determine the specific application or purpose for which you will be using the aluminum sheet. Different projects may require different thicknesses based on the structural or aesthetic requirements. For instance, if you are using aluminum sheets for roofing or siding, a thicker gauge might be necessary to provide sufficient durability and resistance to weather conditions. Secondly, you should consider the level of strength and rigidity required. Thicker aluminum sheets generally offer greater strength and stability, which is crucial for applications such as construction or automotive components. However, keep in mind that thicker sheets may also be heavier and more difficult to work with, so consider the practicality and weight limitations of your project. Additionally, it is important to think about the size of the aluminum sheet you need. Larger sheets may require thicker gauges to maintain their structural integrity, while smaller sheets may not need as much thickness. Lastly, consider your budget. Thicker aluminum sheets can be more expensive due to the increased material cost and manufacturing process. Strike a balance between the required thickness and your budget constraints to ensure you make a cost-effective decision. In summary, choosing the right thickness for your aluminum sheet involves considering the specific application, required strength, size, and budget. It is recommended to consult with industry experts or suppliers who can provide guidance and advice based on your specific needs.

- Q: just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- You MUST use 100% Ar for MIG welding aluminum. Molten Al is highly reactive. Al powder is the active ingredient in thermite, for example. It will react with CO2, stripping away the oxygen and creating a nasty mess. Also, you really need a MIG welder with twice as much current output. along the lines of 200-300 amps. 130 amps will not perform well even with a spool gun, and running the weak, prone-to-jamming .030 Al wire. You could try to do it that way, but I would not advise. (There is no way in hell you'd be able to cram wimpy .030 Al wire through a 6 foot traditional welding lead. It'll kink and jam after 5 seconds.) MIG welding aluminum REQUIRES using the high-current, high feed speed, spray transfer mode. Here are some typical parameters: 030 wire, 500 IPM, 22 volts. 120-130 amps. 035 wire, 500 IPM, 23 volts, 150 amps. 045 wire, 400 IPM, 24 volts, 200 amps. EDIT, the guy above me has the right idea. They use electricity to force the reaction between aluminum oxide (dissolved in cryolite) and carbon, producing molten Al and CO2 gas. Normally the reaction would tend to go the other way. Aluminum has a higher affinity for oxygen.

- Q: This question asks about the impact of aluminum sheets on the air quality inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality. They are inert materials that do not emit volatile organic compounds (VOCs) or other harmful substances. However, the installation process might involve adhesives or sealants that could release VOCs temporarily. Proper ventilation during and after installation can mitigate this issue. Additionally, aluminum sheets can contribute to better air quality by enhancing thermal performance, reducing energy consumption for heating and cooling, and indirectly lowering emissions from power plants.</p>

- Q: Is it possible to use aluminum sheets for exterior siding purposes?

- <p>Yes, aluminum sheets can be used for siding applications. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It's also resistant to rot, termites, and fire, making it a popular choice for many homeowners and builders. However, it's important to ensure that the aluminum is of high quality and installed correctly to maximize its benefits.</p>

- Q: Is aluminum sheet corrosion-resistant?

- Yes, aluminum sheet is corrosion-resistant due to its natural oxide layer that forms on its surface, protecting it from corrosion and making it suitable for various applications in industries such as construction, automotive, and aerospace.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- Please don't ask diffuse questions. If you mean a solution of aluminum ions Al+3, then no: Al3+ + 3e? ? Al(s) -1.66 Cu2+ + 2e? ? Cu(s) +0.340 Cu+ + e? ? Cu(s) +0.520 If you mean a solution of some unspecified Al compound then maybe, but there's no way to know until you specify the compound.

- Q: What are the potential safety issues associated with the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use, but there are a few considerations. They can be sharp when cut, so proper handling is important to avoid cuts. Aluminum is a good conductor of heat, so care should be taken to avoid burns when handling hot aluminum sheets. Additionally, inhalation of aluminum dust can be harmful, so it's important to work in a well-ventilated area or use a dust mask when cutting or grinding aluminum. In terms of long-term health, there's ongoing debate about the safety of aluminum exposure, but it's generally considered safe when used in accordance with proper safety measures.</p>

- Q: Can aluminum sheets be used for reflectors?

- Indeed, reflectors can utilize aluminum sheets. Renowned for its remarkable reflectivity properties, aluminum emerges as an optimal substance for a multitude of reflector applications. Its exceptional reflectivity empowers it to deftly redirect and bounce light, rendering it fitting for deployment in diverse devices such as illumination apparatus, solar panels, telescopes, and other instruments that necessitate precise and effective light reflection. Moreover, aluminum's lightweight nature, durability, and resistance to corrosion render it a pragmatic selection for reflectors that must endure formidable environmental circumstances.

- Q: What are the different types of coatings applied to aluminum sheet?

- There are several types of coatings that can be applied to aluminum sheets. Some common ones include anodizing, powder coating, and organic coatings. Anodizing involves creating an oxide layer on the surface of the aluminum, providing corrosion resistance and enhancing durability. Powder coating involves applying a dry powder to the aluminum surface and then curing it to create a protective and decorative layer. Organic coatings, such as paints or lacquers, can be applied to aluminum sheets to provide color, protection, and aesthetic appeal.

Send your message to us

3003 Aluminum Sheets for Milagros - Cold Rolling Aluminum for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords