Aluminum AW-3005 PE Coated Aluminium Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of EN AW - 3005 PE Coated Aluminium Composite Panels Description

Mill Finished EN AW - 3005 PE Coated Aluminium Composite Panels is one semi-finished aluminium material. The alloy AA3005 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 3005 PE Coated Aluminium Composite Panels

EN AW - 3005 PE Coated Aluminium Composite Panels | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 3005 PE Coated Aluminium Composite Panels

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 3005 PE Coated Aluminium Composite Panels

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 3005 PE Coated Aluminium Composite Panels

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

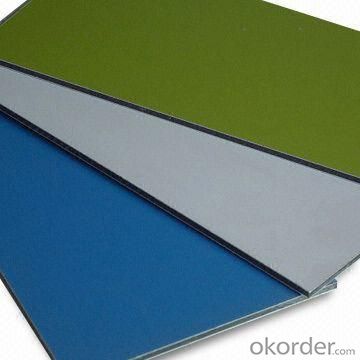

6. Image of EN AW - 3005 PE Coated Aluminium Composite Panels

7. Package and shipping of EN AW - 3005 PE Coated Aluminium Composite Panels

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to utilize recycled aluminum for the production of jewelry and fashion accessories?

- <p>Yes, recycled aluminum can be used to make jewelry and other fashion accessories. Recycled aluminum is a sustainable and cost-effective alternative to new aluminum, and it maintains the same properties as newly mined aluminum. It is lightweight, durable, and can be easily molded into various shapes and designs. Many fashion designers and jewelers are increasingly using recycled aluminum to create unique and eco-friendly products, reducing the environmental impact of their creations.</p>

- Q: Is it possible to utilize recycled aluminum for the production of cars or other types of vehicles?

- <p>Yes, recycled aluminum can be used to make cars and other vehicles. It is common practice in the automotive industry to use recycled aluminum in the manufacturing process due to its lightweight and strong properties. Recycled aluminum requires less energy to produce than new aluminum, making it more sustainable. It is used in various parts of vehicles, including engine components, body panels, and wheels. The use of recycled aluminum not only reduces waste but also contributes to energy savings and carbon emission reductions in vehicle production.</p>

- Q: This question asks whether it is safe to use aluminum cookware for pregnant women or individuals with health conditions.

- <p>While aluminum cookware is generally safe for most people, there are concerns about its potential health effects. Aluminum has been linked to cognitive issues and Alzheimer's disease, although the evidence is not conclusive. For pregnant women and those with health conditions, it is advisable to err on the side of caution. Opt for cookware made from stainless steel, cast iron, or non-stick materials without aluminum. If you must use aluminum cookware, avoid acidic or alkaline foods and ensure the cookware is not scratched, as this can increase aluminum leaching into food.</p>

- Q: Explain how aluminum production and use contribute to global warming.

- <p>Aluminum production contributes to global warming through the emission of greenhouse gases, primarily carbon dioxide. The process of smelting aluminum from bauxite ore is energy-intensive, often relying on fossil fuels, which release CO2. Additionally, aluminum production generates perfluorocarbons (PFCs), potent greenhouse gases. The use of aluminum in various industries and products also has an indirect impact, as it drives demand for energy and resources. Furthermore, aluminum's longevity in landfills means it doesn't decompose, contributing to waste issues and indirectly affecting global warming through methane emissions from landfills.</p>

- Q: This question asks for the typical origins of aluminum in the environment.

- <p>Aluminum is the most abundant metal in the Earth's crust, and it is widely present in the environment. Common sources include: 1) Natural weathering of rocks and soil, which releases aluminum into the environment. 2) Industrial processes such as aluminum production, which can release aluminum into the air and water. 3) Food and water, where aluminum can be found naturally or as a result of contamination. 4) Household products like aluminum foil, cans, and cookware, which can contribute to aluminum exposure. 5) Medications and vaccines, which sometimes contain aluminum as an adjuvant. 6) Cosmetics and personal care products, which may contain aluminum compounds. These sources contribute to the overall aluminum exposure in the environment and to humans.</p>

- Q: This question asks about the process of producing aluminum, a common metal known for its lightweight and corrosion resistance.

- <p>Aluminum is made through a process called electrolysis. The primary source of aluminum is bauxite ore, which is first refined to produce aluminum oxide. This aluminum oxide is then dissolved in a molten cryolite bath and subjected to electrolysis. A large electric current is passed through the bath, causing the aluminum oxide to break down into aluminum metal and oxygen gas. The aluminum metal sinks to the bottom of the cell and is then tapped off and further processed. This process, known as the Hall-H茅roult process, is the predominant method for producing aluminum on an industrial scale.</p>

- Q: Is it safe to use aluminum containers for food and drink in a microwave?

- <p>Aluminum is not recommended for use in microwave-safe containers for food and drink. While some aluminum containers are designed to be microwave-safe, they are typically coated with a non-metallic material to prevent arcing and damage to the microwave. However, most aluminum containers are not safe for microwave use as they can cause sparks and potentially damage the microwave. It's best to use microwave-safe plastics, glass, or ceramics specifically designed for microwave use.</p>

- Q: Is aluminum a component in the manufacturing processes of glass and ceramics?

- <p>Aluminum can be used in the production of glass and ceramics, although it is not a primary component. In glassmaking, aluminum is sometimes added to reduce the coefficient of expansion, making the glass more resistant to thermal shock. It can also improve the chemical durability and electrical insulation properties of the glass. In ceramics, aluminum compounds are used as opacifiers, colorants, or to enhance the mechanical properties of the final product. However, the use of aluminum in these industries is typically in small quantities and serves specific purposes rather than being a fundamental part of the material composition.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

- Q: Is aluminum a suitable material for constructing aerospace structures?

- <p>Yes, aluminum is widely used in aerospace structures due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is particularly favored for aircraft frames, wings, and fuselage components. Aluminum alloys are also used in spacecraft and satellite structures for their lightweight properties and ability to withstand extreme temperatures.</p>

Send your message to us

Aluminum AW-3005 PE Coated Aluminium Composite Panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords