3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of 3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

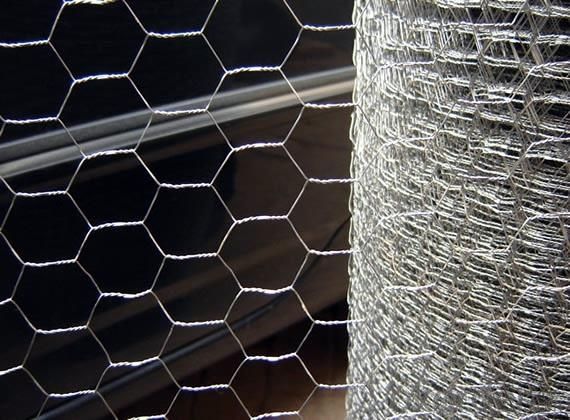

Galvanized Hexagonal Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire.

Application of 3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

Galvanized Hexagonal Wire Mesh is widely used in industrial and agricultural constructions, Rockwool, fence for poultry cage, fishing cage, playground fence and Christmas decorations

Surface treatment of 3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Stainless Steel Wire

Advantage of 3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

Our Galvanized Hexagonal Wire Mesh has strong corrosion-resisting and oxidation-resisting, stable shape, clean ends, good packing with good quality and rock bottom price.

Packing of 3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

1. Waterproof paper then PVC shrinked

2. PVC shrinked only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

Pictures of 3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

Specification of Galvanized Hexagonal Wire Mesh

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

3/8 | 10 | 27; 26; 25; 24; 23 | 0.40-0.63 | 12-48 | 0.3-1.2 |

1/2 | 13 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

5/8 | 16 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-48 | 0.3-1.2 |

3/4 | 19 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1 | 25 | 27; 26; 25; 24; 23; 22; 21; 20 | 0.40-0.88 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 24; 23; 22; 21; 20; 19; 18 | 0.56-1.25 | 12-48 | 0.3-1.2 |

1-1/2 | 40 | 23; 22; 21; 20; 19; 18 | 0.63-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17; 16; 15 | 0.63-1.83 | 12-80 | 0.3-2.0 |

4 | 100 | 16; 15; 14; 13; 12 | 1.65-2.77 | 20-160 | 0.5-4.0 |

Mesh Opening | Wire Thickness | Width | |||

inch | mm | bwg | mm | inch | m |

1 | 25 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/4 | 30 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

1-1/2 | 40 | 25; 24; 23; 22; 21; 20; 19; 18 | 0.51-1.25 | 12-80 | 0.3-2.0 |

2 | 50 | 25; 24; 23; 22; 21; 20; 19; 18; 17 | 0.51-1.47 | 12-80 | 0.3-2.0 |

3 | 75 | 23; 22; 21; 20; 19; 18; 17 | 0.63-1.47 | 12-80 | 0.3-2.0 |

FAQ

1. What is the storage condition?

The Galvanized Hexagonal Wire Mesh should be stored at room temperature and kept from wet and heat source.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How does the diameter of the wire affect the strength of steel wire mesh?

- The diameter of the wire has a direct impact on the strength of steel wire mesh. Generally, a larger diameter wire will result in a stronger mesh because it can withstand greater tension and load. Thicker wires have more material, which increases their resistance to bending and breaking. Therefore, increasing the diameter of the wire used in steel wire mesh enhances its overall strength.

- Q: What are the different weaving patterns used in steel wire mesh?

- Steel wire mesh utilizes various weaving patterns, each possessing unique qualities and purposes. 1. The Plain Weave, known for its consistent and robust nature, interlaces wires in an over-under manner to form a square or rectangular mesh. This versatility makes it applicable for filtration, screening, and reinforcement needs. 2. Twill Weave, on the other hand, weaves wires in a diagonal fashion, creating a distinct twill effect. This pattern offers stability and strength, making it ideal for heavy-duty applications like conveyor belts and architectural facades. 3. Dutch Weave distinguishes itself through a thicker warp wire and a finer weft wire, resulting in a tighter mesh structure. This enhanced filtration capability finds application in industries such as oil and gas, chemical processing, and food processing. 4. Reverse Dutch Weave, in contrast, flips the Dutch weave pattern by using a thicker weft wire and a finer warp wire. This configuration ensures exceptional strength and durability, while still maintaining excellent filtration properties. It is often employed in pressure filters and hydraulic systems. 5. Twilled Dutch Weave effectively combines the features of twill weave and Dutch weave. By incorporating a double layer of weft wires, this pattern offers heightened strength and finer filtration capabilities. It is commonly utilized in high-pressure filtration scenarios, such as gas and liquid separation. Each weaving pattern possesses distinct advantages and suitability for specific applications. The selection of the weaving pattern relies on factors like desired mesh structure, filtration requirements, and the necessary strength and durability for the intended application.

- Q: How does steel wire mesh perform in terms of resistance to abrasion?

- Steel wire mesh performs exceptionally well in terms of resistance to abrasion. The high tensile strength of steel combined with the interlocking nature of the mesh design makes it highly resistant to wear and tear caused by rubbing or scraping against other surfaces. This makes it a preferred choice for applications that require durability and longevity, such as in construction, industrial settings, and reinforcement in concrete structures. The sturdy construction of the steel wire mesh ensures that it can withstand the impact of abrasive materials and maintain its integrity over time, making it an excellent option for environments where abrasion resistance is crucial.

- Q: Can steel wire mesh be used for automotive grilles?

- Automotive grilles can indeed utilize steel wire mesh. The reason behind its popularity in this application is its endurance, robustness, and ability to resist corrosion. It ensures the radiator and other vital parts of the vehicle remain safeguarded while facilitating sufficient air circulation. Moreover, steel wire mesh grilles are frequently employed for aesthetic reasons, as they enhance the overall look of the vehicle. What's more, installing and maintaining steel wire mesh is relatively effortless, rendering it a practical option for automotive grilles.

- Q: Can steel wire mesh be used for creating gabion mattresses?

- Yes, steel wire mesh can be used for creating gabion mattresses. Gabion mattresses are typically made by filling steel wire mesh containers with stones or other fill materials to create erosion control structures. The steel wire mesh provides structural integrity and stability to the gabion mattress, making it an ideal material for this purpose.

- Q: What are the different edge treatments available for steel wire mesh?

- Steel wire mesh offers various edge treatments, each with a distinct purpose and unique advantages. One prevalent edge treatment is the selvage edge, which forms by looping the wire strands back into the mesh. This reinforcement prevents the mesh from unraveling or fraying, making it ideal for high tension or stress applications like fencing or industrial use. Another option is the knuckled edge, where wire strands are gently bent back in a curve. This type of edge is commonly found in chain link fencing, offering a safe and smooth edge that reduces the risk of injury and minimizes snagging or tearing of clothing and other materials. For applications requiring a sturdy and secure edge, a barbed or twisted edge can be employed. This involves bending the wire strands at the edge into sharp barbs or twists, ensuring extra security and preventing unauthorized access or tampering. Barbed or twisted edges are often utilized in high-security fencing or perimeter protection systems. In certain cases, a reinforced edge treatment may be necessary to enhance the mesh's strength and durability. This can be achieved by adding an extra layer of wire or a metal strip along the edge, promoting stability and preventing deformation or sagging. Ultimately, the choice of edge treatment for steel wire mesh depends on the specific application and requirements. Factors such as strength, safety, durability, and aesthetics should be considered when selecting the appropriate edge treatment. Seeking guidance from a knowledgeable supplier or manufacturer can help determine the most suitable edge treatment for a particular project.

- Q: What are the benefits of using steel wire mesh in the telecommunications manufacturing industry?

- There are several benefits of using steel wire mesh in the telecommunications manufacturing industry. Firstly, steel wire mesh provides excellent strength and durability. It can withstand harsh environmental conditions and is resistant to corrosion, making it ideal for outdoor installations. This strength and durability ensure that the telecommunications infrastructure remains intact and reliable, reducing the need for frequent repairs or replacements. Secondly, steel wire mesh offers superior protection and security. It acts as a physical barrier, preventing unauthorized access to sensitive equipment and infrastructure. This helps to safeguard the telecommunications network against vandalism, theft, or any other malicious activities, ensuring uninterrupted communication services. Additionally, steel wire mesh provides excellent electromagnetic shielding properties. It can effectively block electromagnetic interference (EMI) and radio frequency interference (RFI). This shielding capability is crucial in the telecommunications industry as it helps to maintain signal quality and prevent disruptions or distortions in communication. Moreover, steel wire mesh is highly versatile and can be easily customized to meet specific requirements. It can be manufactured in various sizes, shapes, and configurations to suit different applications, such as cable trays, enclosures, or fencing. This flexibility enables telecommunications manufacturers to design and build infrastructure solutions that perfectly fit their needs. Lastly, steel wire mesh is a cost-effective solution. Its long lifespan and low maintenance requirements result in reduced operational expenses over the long term. Additionally, its recyclability makes it an environmentally friendly choice, aligning with sustainability goals. In summary, the benefits of using steel wire mesh in the telecommunications manufacturing industry include strength and durability, protection and security, electromagnetic shielding, versatility, and cost-effectiveness. These advantages make it an ideal material for building reliable and secure telecommunications infrastructure.

- Q: Can steel wire mesh be used for animal cages?

- Yes, steel wire mesh can be used for animal cages. Steel wire mesh is a durable and strong material that provides excellent containment for animals. It is commonly used for constructing cages and enclosures for a variety of animals, including small pets, birds, and large animals such as dogs and livestock. Steel wire mesh is resistant to chewing and scratching, making it an ideal choice for keeping animals safely contained. Additionally, the mesh design allows for ventilation and visibility, ensuring that animals are comfortable and easily observed. However, it is important to select the appropriate gauge and spacing of the wire mesh to ensure that the animals cannot escape or get injured.

- Q: How does steel wire mesh perform in radio frequency shielding?

- Steel wire mesh can be an effective material for radio frequency shielding due to its conductivity and ability to block electromagnetic waves. When used as a barrier, steel wire mesh creates a Faraday cage, which is a structure that prevents the penetration or escape of electromagnetic fields. The mesh acts as a conductor, allowing the electromagnetic waves to flow through it but also dissipating the energy by converting it into heat. This property helps in attenuating or reducing the intensity of radio frequency signals, effectively shielding the surrounding area from unwanted interference. Additionally, steel wire mesh is highly durable and can provide a long-lasting solution for radio frequency shielding, making it suitable for various applications such as in electronic enclosures, data centers, or even in architectural designs where RF interference needs to be minimized. Moreover, the size and spacing of the wires in the mesh can be tailored to specific frequencies, allowing for customization and optimization of the shielding performance. However, it is important to note that the effectiveness of steel wire mesh in radio frequency shielding can be influenced by factors such as the mesh size, wire thickness, and the overall design and installation of the shielding system.

- Q: Can steel wire mesh be used for anti-slip surfaces and walkways?

- Yes, steel wire mesh can be used for anti-slip surfaces and walkways. The mesh provides a textured and rough surface, ensuring better traction and reducing the risk of slipping. Additionally, its durable and strong properties make it suitable for heavy foot traffic areas.

Send your message to us

3" Diameter Zinc Galvanized Hexagonal Wire Mesh for Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches