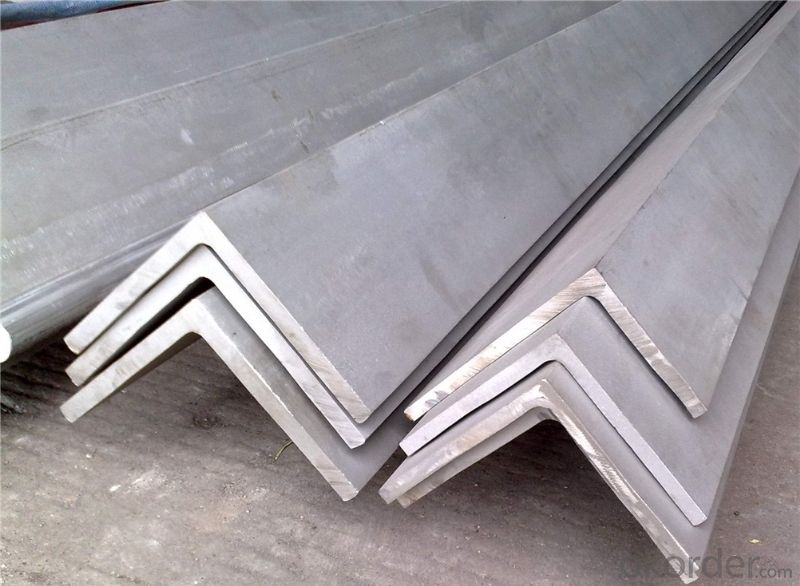

20mm*2.5mm hot sell Equal Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | |||

Mo | 2.0-3.0 | ||||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How do you calculate the strength of a steel angle?

- Calculating the strength of a steel angle requires consideration of several factors. Important parameters to take into account include the angle's dimensions, the steel's material properties, and the applied load or force. Firstly, determining the dimensions of the angle is necessary. This entails measuring the lengths of both legs and the angle's thickness. These measurements are crucial for calculating the area moment of inertia, which plays a vital role in determining the angle's strength. Next, knowledge of the steel angle's material properties is essential. This includes information on the yield strength, ultimate tensile strength, and modulus of elasticity. Material specifications or testing can be used to obtain these properties. Once the dimensions and material properties are known, the strength of the steel angle can be calculated using various formulas and equations. One commonly used approach involves calculating the section modulus, which measures the angle's resistance to bending. The section modulus can be determined using the formula Z = (b × h^2)/6, where b represents the angle's thickness and h corresponds to the distance between the centroid of the angle and the outer edge. To determine the strength of the angle, it is necessary to compare the applied load or force with the calculated section modulus. If the applied load falls within the limits of the section modulus, the angle is considered structurally sound. However, if the applied load exceeds the section modulus, there is a risk of failure. It's important to note that the strength calculations for a steel angle are based on assumptions and ideal conditions. Real-world factors such as material imperfections, fabrication processes, and load distribution can affect the actual strength of the angle. Therefore, it is advisable to consult structural engineers or reference design codes to ensure accurate calculations and safe design.

- Q: Can steel angles be used in the construction of shopping malls?

- Shopping malls can indeed incorporate steel angles in their construction. These versatile structural components offer support and stability to different parts of a building, such as shopping malls. The construction industry often employs steel angles for framing, bracing, and reinforcing structures. Their usage extends to supporting the walls, roof, and floors of shopping malls, thereby guaranteeing the building's structural integrity. Moreover, they come in handy when constructing staircases, escalators, and mezzanines within the shopping mall. The inclusion of steel angles in shopping mall construction presents numerous benefits, including their durability, strength, and cost-effectiveness.

- Q: How do steel angles perform under lateral or wind loading conditions?

- Steel angles are commonly used in construction and engineering applications due to their strength and versatility. When it comes to lateral or wind loading conditions, steel angles perform exceptionally well. Lateral loading refers to forces that act in a horizontal direction, perpendicular to the axis of the angle. Steel angles, with their inherent rigidity and ability to resist bending, are capable of withstanding significant lateral loads. This makes them ideal for applications such as bracing systems, support structures, and framing components that need to resist wind, seismic, or other lateral forces. Similarly, steel angles excel in wind loading conditions. Wind exerts a strong lateral force on structures, and steel angles can effectively counteract these forces. By securely fastening steel angles to the structure, they can provide stability and prevent the structure from being compromised by wind-induced vibrations or even collapse. The performance of steel angles under lateral or wind loading conditions can be further enhanced through proper design and installation. Engineers often consider factors such as the size and thickness of the angle, the type and quality of the steel used, and the connection details. By carefully analyzing the specific loading conditions and selecting appropriate steel angles, engineers can ensure that structures remain stable and safe, even under extreme lateral or wind loads. Overall, steel angles are highly reliable and durable when it comes to lateral or wind loading conditions. Their robustness, coupled with their cost-effectiveness and ease of installation, makes them a preferred choice in many construction and engineering projects.

- Q: Are steel angles suitable for rooftop installations?

- Yes, steel angles are suitable for rooftop installations. Steel angles are commonly used in construction for their strength and durability. They are particularly useful for rooftop installations due to their ability to provide structural support and stability. Steel angles can be used to secure various rooftop equipment such as solar panels, HVAC units, communication antennas, and satellite dishes. Additionally, steel angles are resistant to weathering, corrosion, and fire, making them a reliable choice for rooftop installations.

- Q: How do you determine the strength of a steel angle?

- The strength of a steel angle can be determined by considering its dimensions, material properties, and the load it will be subjected to. Factors such as the thickness and width of the angle, as well as the type and grade of steel used, play a crucial role in its strength. Additionally, analyzing the applied load, whether it's a tensile, compressive, or bending force, helps assess the angle's strength based on its ability to withstand and distribute the load without failure. Various mathematical calculations and engineering standards can be used to determine the strength of a steel angle in specific applications.

- Q: Can steel angles be used for support structures in sports facilities?

- Steel angles have the capability to be utilized as support structures in sports facilities. Due to their superior strength and durability, steel angles are frequently employed in construction projects. They offer exceptional support and stability, rendering them appropriate for a variety of applications in sports facilities, including supporting beams, columns, and trusses. Steel angles are capable of effectively handling heavy loads and enduring the dynamic forces that arise in sports facilities, thus making them a dependable choice for support structures. Furthermore, steel angles can be easily manufactured, allowing for customization to fulfill specific design requirements. In conclusion, steel angles are a versatile and extensively utilized material for support structures in sports facilities.

- Q: Can steel angles be used for sign posts?

- Certainly! Sign posts can indeed utilize steel angles. Due to their robustness and endurance, steel angles are frequently employed in construction. They can effectively offer the required support and stability for sign posts, particularly in regions prone to strong winds or heavy traffic. Moreover, the versatility of steel angles shines through as they can be effortlessly welded or bolted together, presenting an adaptable choice for sign post installation. Furthermore, their immunity to corrosion guarantees a lengthier lifespan, thereby diminishing expenses associated with maintenance and replacement.

- Q: How do you determine the required number of fasteners for a steel angle connection?

- To determine the required number of fasteners for a steel angle connection, several factors need to be considered. These include the load being applied, the size and thickness of the angle, the type and strength of the fasteners being used, and any applicable building codes or engineering standards. Typically, calculations or guidelines provided by structural engineers or industry standards are used to determine the minimum number and spacing of fasteners needed to ensure the connection is strong and safe.

- Q: Can steel angles be used for fencing or security applications?

- Certainly! Steel angles have a wide range of applications, including fencing and security. In construction, steel angles are widely utilized due to their exceptional strength and durability. When employed for fencing purposes, steel angles offer a solid framework capable of enduring adverse weather conditions and potential impacts. By welding or bolting them together, a secure and resilient fence structure can be created. Moreover, steel angles are also suitable for security applications like gates, barriers, and grills. Their robustness makes them an excellent option for reinforcing security measures and guaranteeing the safety of a property.

- Q: How are steel angles protected against impact or collision damage?

- Steel angles can be protected against impact or collision damage through various methods. One common approach is to use protective barriers or bollards strategically placed around the angles to absorb the impact and prevent direct contact. These barriers can be made from materials such as concrete, rubber, or steel, depending on the level of protection required. Another method is to install impact-resistant guards or shields directly on the steel angles. These guards are typically made of materials like polyethylene, rubber, or heavy-duty plastic, which can absorb the impact and minimize damage to the angles. In some cases, additional reinforcement, such as steel plates or bars, can be incorporated into the guards for enhanced protection. Furthermore, steel angles can be coated or painted with impact-resistant coatings or paints. These coatings are designed to absorb and disperse the force of an impact, reducing the likelihood of damage. Additionally, they can provide an extra layer of protection against corrosion, which further safeguards the angles from deterioration due to impact. Lastly, engineering and design considerations can also help protect steel angles against impact damage. By properly evaluating the structural requirements and potential risks, engineers can choose appropriate dimensions, materials, and reinforcement techniques to enhance the angles' resistance to collision damage. This includes considering factors such as load-bearing capacity, impact force distribution, and structural integrity. Overall, the protection of steel angles against impact or collision damage involves a combination of physical barriers, guards, coatings, and thoughtful engineering. These measures aim to minimize the risk of damage, prolong the lifespan of the angles, and ensure their structural integrity in various applications.

Send your message to us

20mm*2.5mm hot sell Equal Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords