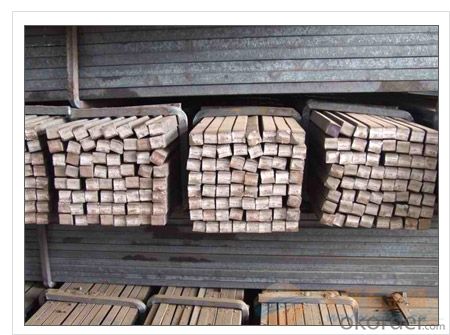

16MnSi High Quality Steel Square Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

In the production of steel products, steel is molded and reshaped with different machinery at different temperatures. One process is steel rolling, which involves metal stock passing through a pair of rolls. Rolling produces flat steel sheets of a specific thickness, and the process is classified according to the temperature at which the metal is rolled. If the temperature of the metal is above its recrystallization temperature, or the temperature at which the grain structure of the metal can be altered, then the process is termed as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is termed as cold rolling.

Like cold rolling, cold drawing is performed at room temperature, but instead of producing a flat object like a coke can, cold drawing makes steel into the form of a wire like the spokes of a wheel or a paper clip. To start the process, Steel is usual hammered and rolled so that it can be fit through a die; a tool that turns the steel mass into a wire. The room temperature steel is pulled through the die which reshapes it into a thinner shape while maintaining the same volume. It is similar to the idea of syrup flowing out of a bottle through a tube in that it changes shape but not volume, but instead of squeezing the metal, it is pulled out. In order to get the wire down to the right diameter, it usually requires more than one pass through different dies.

Colddrawn steel, steel covered carbon steel, excellent carbon steel, alloy structural steel, carbon tool steel, spring steel, bearing steel, tool steel, cold heading steel, free cutting steel, martensite stainless steel; products include all kinds of shapes round, square steel, hexagonal, flat steel and other conventional products, including various special-shaped steel products. In all types of colddrawn steel industry has been widely used, these areas include automotive, machine tools, furniture, standard parts, textile machinery, agricultural machinery, military industry and other industries.

The total assets of more than 40 million, as of the end of 2010 with fixed assets of 34 million, with 60 tons from 5 tons a chain drawing machine 10 sets, horizontal and inverted coiled wire drawing machine 5 sets, steel and plate production line of blasting, high-power ham stove, various straightening machine and cold rolling mill and other major equipment.

Usage/Applications

-The Square Bar is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks: We make tag marks and color marks. The tag marks with white background and red company logo will be tied up to each bundle of the products. The information is usually including basic information of products and company and other information requested by customers. As for color marks, we will paint both ends of bundles to make sure that it w

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

ill be more convenient for customers to distinguish them from other products.

- Q: Can a steel square be used for pergola construction?

- Yes, a steel square can be used for pergola construction. Steel squares are versatile tools that can be utilized for various construction tasks, including measuring, marking, and checking angles. They can help ensure accurate and precise cuts and angles when constructing a pergola.

- Q: What are the different techniques for using a steel square in metalworking fabrication?

- Metalworking fabrication offers a range of techniques for utilizing a steel square. To begin with, one frequently employed method involves measuring and marking right angles. This is accomplished by placing the blade, or long side, against the metal's edge and sliding the square along while marking the desired angle. This guarantees a perfect square angle. Another technique entails using the steel square as a cutting guide. By securely clamping the square to the metal sheet, one can achieve precise and straight cuts by running a cutting tool, such as a grinder or saw, along the square's edge. This is particularly valuable for creating clean edges and making accurate cuts for joints or corners. Furthermore, the steel square can be employed to inspect the flatness or straightness of a metal surface. By positioning the square against the metal and observing the gap between the blade and the surface, one can identify any imperfections or unevenness. This is especially crucial when working on projects that require precise measurements or when ensuring accurate component fitting. Additionally, the steel square serves as a guide for drilling holes in metal. By aligning the desired drill location with the appropriate markings on the square and positioning it against the metal surface, one can achieve accurate and consistent hole placement. Lastly, the steel square can function as a layout tool. By using the square to mark lines or angles on the metal, fabricators can ensure proper alignment and symmetry in their workpieces. This is particularly beneficial when working on intricate or complex designs that necessitate precise measurements and angles. In conclusion, the utilization of a steel square in metalworking fabrication encompasses techniques such as measuring and marking right angles, guiding cutting tools, checking flatness or straightness, guiding drilling operations, and serving as a layout tool. These techniques enable fabricators to achieve accurate and precise results in their metalworking projects.

- Q: What are some common uses for a steel square in box making?

- Some common uses for a steel square in box making include measuring and marking right angles, checking for squareness and alignment of box corners, ensuring accurate and precise cuts, and verifying the straightness of box sides and edges.

- Q: How do you use a steel square to determine the angle of a miter cut?

- To determine the angle of a miter cut with a steel square, follow these steps: 1. Position the steel square against the material's edge, ensuring the long side aligns with the edge, at a 90-degree angle. 2. Use a pencil or marker to draw a line along the inside edge of the square, representing the 90-degree angle. 3. Adjust the steel square along the edge until the desired miter cut angle is achieved. For example, if you want a 45-degree miter cut, align one of the square's edges with the previously drawn line at the 90-degree angle. 4. Once the steel square is aligned for the desired angle, draw another line along the inside edge of the square, representing the miter cut angle. 5. Connect the starting point of the 90-degree line with the endpoint of the miter cut line using a straight edge or ruler. This will create an accurate cutting guide representing the miter cut angle. By employing a steel square in this manner, you can effortlessly determine and mark the precise angle for a miter cut, ensuring precise and accurate cuts in your woodworking or construction projects.

- Q: Can a steel square be used for checking the squareness of a router table fence?

- Yes, a steel square can be used for checking the squareness of a router table fence. A steel square is a reliable tool for measuring angles and ensuring that two surfaces are perpendicular to each other. To check the squareness of a router table fence, simply place the steel square against the fence and the table surface, making sure it sits flush against both surfaces. If the steel square forms a perfect 90-degree angle with the fence and table, then the fence is square. If there is any gap or the angle is not 90 degrees, adjustments can be made to align the fence properly.

- Q: Can a steel square be used for fence installation?

- Fence installation can indeed utilize a steel square. This versatile tool, also referred to as a framing square or carpenter's square, boasts a multitude of construction applications, including fence installation. Comprised primarily of steel, it consists of a lengthy blade and a shorter tongue, which combine to form a right angle. Within the realm of fence installation, a steel square serves the purpose of guaranteeing that the posts are both set at the appropriate depth and are plumb (vertically aligned) and level (horizontally aligned). It can also be employed to measure and mark the precise locations for the fence posts, ensuring that they are evenly spaced and properly aligned. Furthermore, a steel square can be utilized to assess the corners for squareness and to verify that the rails and pickets are installed at the correct angles. In summary, the inclusion of a steel square proves to be invaluable during the fence installation process, as it plays a crucial role in maintaining accuracy, precision, and proper alignment throughout.

- Q: What are some common applications for a steel square in stair construction?

- Some common applications for a steel square in stair construction include measuring and marking the angles for cutting stair stringers, determining the rise and run of each step, checking the levelness and squareness of the stairs, and ensuring accurate and precise construction of the stair components.

- Q: Can a steel square be used for gazebo post layout and installation?

- Yes, a steel square can be used for gazebo post layout and installation. A steel square, also known as a framing square or a carpenter's square, is a versatile tool commonly used in construction and woodworking. It consists of a long blade and a shorter tongue that meet at a 90-degree angle, allowing for accurate measurements and layout. When it comes to gazebo post layout and installation, a steel square can be a valuable tool. It can assist in determining the correct angles and measurements for positioning the posts, ensuring that they are level and aligned properly. To use a steel square for gazebo post layout, you can use it to mark out the corners and angles where the posts should be placed. By aligning the blade or the tongue of the square with the edges of the gazebo base or the desired position of the posts, you can ensure accurate measurements and angles. During installation, a steel square can also be handy for checking that the posts are plumb and level. By placing the square against the sides of the posts, you can verify if they are perfectly vertical or if adjustments need to be made. In summary, a steel square can certainly be used for gazebo post layout and installation. Its versatility and accuracy make it a useful tool for ensuring that the posts are positioned correctly and are level.

- Q: What are some common safety precautions to follow when using a steel square?

- Some common safety precautions to follow when using a steel square include wearing appropriate personal protective equipment (such as safety glasses and gloves), properly securing the workpiece, ensuring the steel square is clean and in good condition, using the square on a stable and level surface, and being cautious of sharp edges. It is also important to handle the steel square with care to avoid injury, and to follow any specific safety guidelines provided by the manufacturer.

- Q: What are some common measurements that can be taken with a steel square in sheet metal work?

- Some common measurements that can be taken with a steel square in sheet metal work include determining angles, checking for squareness, measuring the thickness of sheet metal, and marking straight and parallel lines. Firstly, a steel square can be used to measure and mark angles. By aligning the square's edge with the desired angle, one can accurately mark the sheet metal for cutting or bending. The square's markings, such as those for 45-degree or 90-degree angles, assist in achieving precise measurements. Secondly, a steel square is essential for checking squareness. It ensures that corners or edges of the sheet metal are perfectly perpendicular to each other. By aligning the square's edge against a corner and observing if the other edge aligns perfectly, one can determine if the sheet metal is square or if adjustments need to be made. Additionally, a steel square can be used to measure the thickness of sheet metal. By placing the square against the edge of the metal, one can read the measurement scale on the square to determine the thickness. This information is crucial for selecting appropriate tools, such as shears or punches, for cutting or shaping the sheet metal. Furthermore, a steel square is valuable for marking straight and parallel lines on sheet metal. By using the square's edge as a guide, one can draw precise lines that are parallel to an existing edge or at a specific distance from it. This is particularly important in sheet metal fabrication, where accuracy is crucial for the final product. In summary, a steel square is a versatile tool in sheet metal work, allowing for measurements of angles, checking squareness, measuring thickness, and marking straight and parallel lines. Its accuracy and reliability make it an essential instrument in achieving precise and high-quality sheet metal projects.

Send your message to us

16MnSi High Quality Steel Square Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords