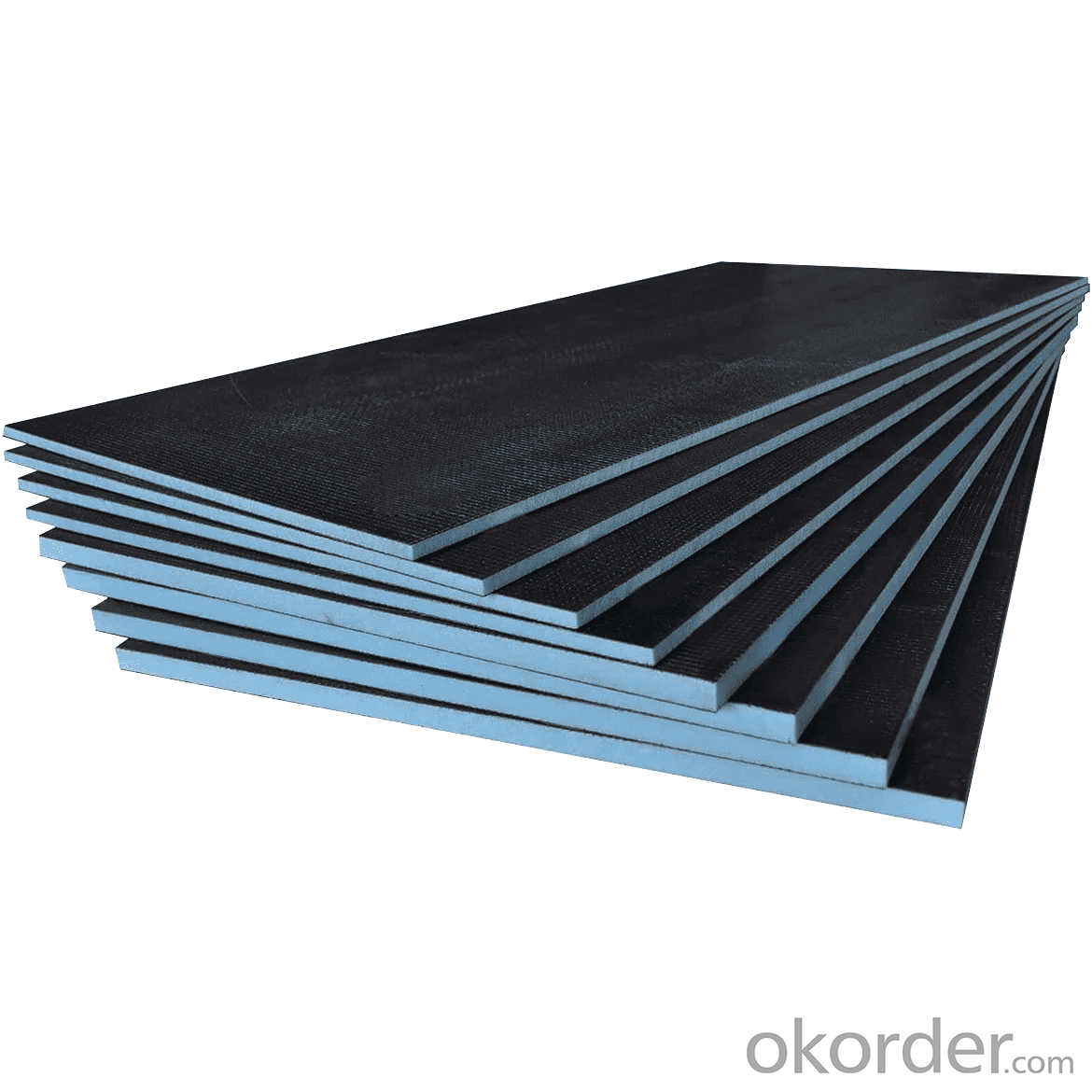

1200x600mm Wetroom 12mm Tile Backer Board For Walls and Floors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wetroom 12mm XPS Tile Backer Board For Walls and Floors 1200mm x 600mm (10 Pack)

When it comes to effective insulation solutions for your construction or tiling projects, XPS insulation boards are a reliable choice. We offer a wide range of XPS insulation boards, also known as XPS foam boards or simply XPS boards. These boards are designed to provide excellent thermal insulation, moisture resistance, and durability, making them ideal for various applications.

XPS insulation boards are constructed from extruded polystyrene foam, known for its high compressive strength and low thermal conductivity. This combination of properties makes XPS boards highly efficient in reducing heat transfer and improving energy efficiency in buildings. Whether you're insulating walls, floors, or roofs, XPS insulation boards offer a reliable solution.

Our selection of XPS foam boards includes various thicknesses and sizes to accommodate different project requirements. From smaller DIY projects to large-scale commercial installations, we have the right XPS insulation board to suit your needs. These boards are easy to handle and cut, allowing for precise fitting and installation.

Our company pride ourselves on providing high-quality products and exceptional customer service. Our knowledgeable staff are available to assist you in selecting the right XPS insulation board for your specific project. We also offer fast shipping and hassle-free returns to ensure your complete satisfaction with your purchase.

Whether you're a professional contractor or a DIY enthusiast, our XPS boards will help you create a comfortable and energy-efficient environment.

Performance parameters

Technical | Assessed to | Rating |

XPS Foam Density | DIN 53420 | 32±0.02kg/m³ |

Compressive strenghth (kPa) | EN 826 | ≥450 |

Thermal conductivity(W/m・K) | EN 12167 | ≤0.030 ≤0.034 |

Dimesional stability % (70±2℃) 48h | GB/T8811-2008 | ≤1.5 |

Flexural Strength (Mpa) | ASTM C203 | ≥2.8 |

Water Absorption(96hrs immersion) | ISO 2896 | ≤1.5 |

Water Vapour Permeability | ASTM E-96 | ≤3.0 |

Flammability | EN13501 | B2 |

Tensile strength perpendicular to the board | GB/T30595-2024 | ≥0.2Mpa |

Advantages

Advantages

1. impact resistant and rigid.

2. Waterproof and temperature resistant & Vapour retardant.

3. Thermally insulating.

4. Quick and easy to install.

5. Lightweight, easy to handle and transport.

6. Easy to cut (with a utility knife).

7. Applied to use on any kind of background substrate.

8. Applied to freestanding p

artition walls,shelves, coverings and similar surfaces.

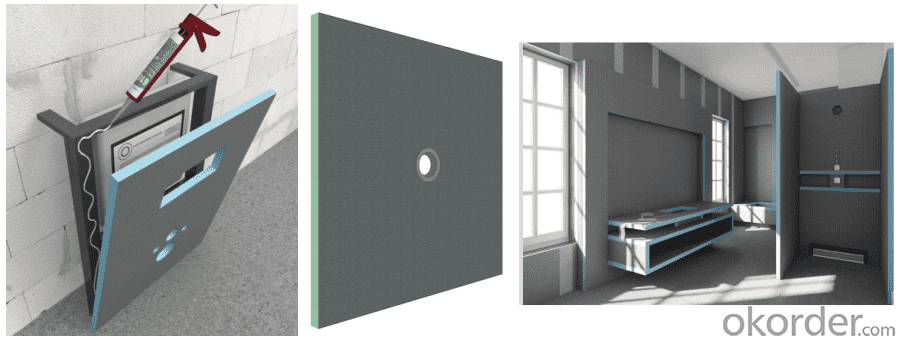

Applications

Bathrooms and Showers: Perfect for walls and floors in showers and bathrooms where water exposure is constant.

Kitchens: Ideal for kitchen backsplashes and countertops, providing a moisture-resistant base.

Wet Rooms: Suitable for creating fully waterproof wet rooms with tiled surfaces.

Exterior Spaces: Can be used in outdoor areas where moisture and temperature changes are a concern.

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are designed to be resistant to frost damage. They are typically made from durable materials that can withstand freezing temperatures without cracking or deteriorating.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oils?

- Typically, waterproofing membranes are resistant to hydrocarbons and oils. The materials utilized in these membranes, such as bitumen or synthetic polymers, are specifically engineered to possess strong resistance against different chemicals, including hydrocarbons and oils. This resistance guarantees that the membrane remains efficient in obstructing water penetration even when confronted with these substances. Nevertheless, it is crucial to acknowledge that the resistance level may differ depending on the type and quality of the waterproofing membrane. It is advisable to consult the manufacturer or supplier to ascertain the precise resistance capabilities of a given waterproofing membrane.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide durability and protect the underlying structures from water damage. They are often used in areas such as basements, balconies, and rooftops, which may experience heavy foot traffic or support heavy loads. However, it is important to choose a membrane specifically designed for high traffic or heavy load areas to ensure it can withstand the intended use.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Yes, a waterproofing membrane can be used on terraces or patios to prevent water penetration and protect the underlying structure from moisture damage.

- Q: Can waterproofing membranes be used on concrete pipes?

- Concrete pipes can indeed utilize waterproofing membranes. These membranes are frequently employed to thwart the ingress of water and safeguard concrete structures against moisture-induced harm. Like any other concrete structure, concrete pipes are vulnerable to water infiltration, which can result in decay and a shortened lifespan. By applying a waterproofing membrane to concrete pipes, a barrier against water can be established, thus averting potential complications such as leaks, cracks, and corrosion. Typically, the membrane is administered to the exterior of the pipe, forming a protective layer that thwarts water from permeating the concrete. This measure contributes to prolonging the pipes' lifespan and guaranteeing their long-standing durability.

- Q: Is a waterproofing membrane resistant to UV radiation?

- Yes, a waterproofing membrane is typically resistant to UV radiation. Most waterproofing membranes are designed to be durable and long-lasting, and part of that includes being able to withstand exposure to UV rays. UV radiation from the sun can cause degradation and damage to various materials over time, including waterproofing membranes. However, manufacturers often incorporate UV stabilizers and additives into the membrane's composition to enhance its resistance to UV radiation. These additives help to prevent the breakdown of the membrane's structure, ensuring that it remains effective in preventing water infiltration and maintaining its overall performance for an extended period, even when exposed to direct sunlight. Additionally, some waterproofing membranes may have a protective layer or coating that offers additional UV resistance. It is always recommended to consult the manufacturer's specifications and guidelines to understand the specific UV resistance capabilities of a particular waterproofing membrane.

- Q: Can a waterproofing membrane be installed under tile or other flooring materials?

- Yes, a waterproofing membrane can be installed under tile or other flooring materials. Waterproofing membranes are commonly used in areas where moisture may be present, such as bathrooms, kitchens, and basements. These membranes act as a barrier, preventing water from seeping through the floor and causing damage to the underlying structure. They are typically applied directly onto the substrate before the tile or flooring material is installed. This ensures that any water or moisture that may penetrate the flooring is redirected and prevented from reaching the subfloor. By installing a waterproofing membrane, you can protect your floors and extend their lifespan while ensuring a dry and moisture-free environment.

- Q: Can waterproofing membranes be used on elevator pits?

- Indeed, elevator pits can benefit from the utilization of waterproofing membranes. Given their underground location, elevator pits are susceptible to water infiltration, which can lead to detrimental water damage and leaks. To combat these moisture-related issues, waterproofing membranes offer a highly effective solution by preventing water penetration and safeguarding elevator pits. Typically composed of rubber, polyurethane, or bitumen, these membranes are specifically designed to create a watertight barrier. Through their application on the walls and floor of the elevator pit, they form a seamless and durable protective layer. As a result, this membrane system ensures the maintenance of a dry pit, consequently preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

- Q: Can a waterproofing membrane be used for planter boxes?

- Yes, a waterproofing membrane can be used for planter boxes. A waterproofing membrane is designed to prevent water from seeping through surfaces and can be an effective solution for preventing water damage to the planter box and its surroundings. By installing a waterproofing membrane on the inside of the planter box, it creates a barrier that keeps water from reaching the underlying materials, such as wood or concrete, and helps to extend the lifespan of the planter box. Additionally, a waterproofing membrane can also help to retain moisture within the planter box, which can be beneficial for the plants growing inside. However, it is important to select a waterproofing membrane that is specifically designed for planter boxes and is safe for use with plants to ensure the best results.

- Q: Can a waterproofing membrane reduce noise transmission?

- Yes, a waterproofing membrane can reduce noise transmission.

Send your message to us

1200x600mm Wetroom 12mm Tile Backer Board For Walls and Floors

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords