Aluminum Sheets Kansas - 1100 3003 5052 5754 5083 6061 7075 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

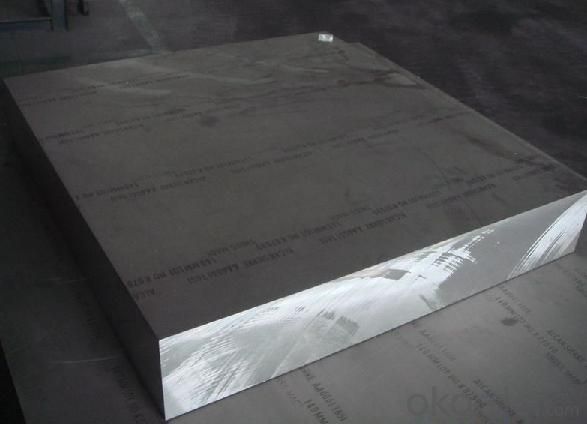

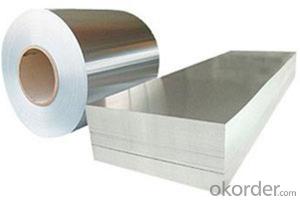

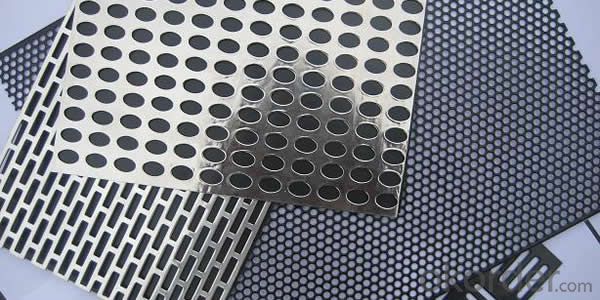

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Application

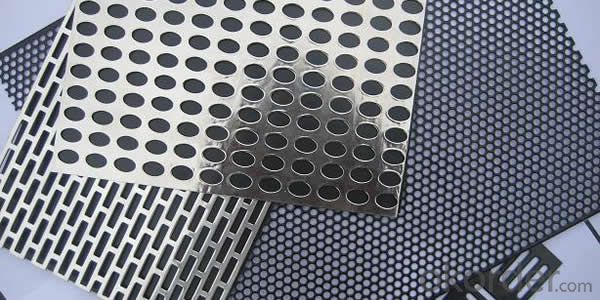

Appplication:construction, decoration, transportation, cookware, machinery, moulding, airplane, PP cap etc

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why CNBM?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q: ... initial temperature of the water or the initial temperature of the aluminum? Why?

- Let's say the aluminum starts out at a higher temperature than the water. The aluminum cools down by 1°C, which means it loses energy (Q = mcΔT, where ΔT = 1°C). That energy goes to the water, warming it up. Since Q is the same for both water and aluminum, and m is the same for both, all that matters is the heat capacity c. Water has a higher heat capacity than aluminum, so for the same Q it must have a smaller ΔT. This process continues until both have reached the same T. From the above paragraph, you should be able to figure out if the final T is closer to the initial water temp or the original aluminum temp.

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: there is a magnet for other type of nails except aluminum nails

- Not that I have heard of. The best way is manual hand pick up. If it is on concrete you might try making a pad out of a good stickey tape (turning the stickey part to the outside) that might speed up the process.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- This Site Might Help You. RE: aluminum boat vs fiberglass? I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum? I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save...

- Q: What are the maximum dimensions of aluminum sheets?

- The maximum dimensions of aluminum sheets can vary depending on the specific manufacturing capabilities and requirements. However, commonly available aluminum sheets often have a maximum width of around 72 inches (6 feet) and a maximum length of approximately 240 inches (20 feet).

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Aluminum forms metallic bonds in the metal and aluminum alloys. Aluminum forms covalent bonds as with aluminum isopropoxide. Aluminum forms ionic bonds as in aluminum sulfate. Aluminum chloride is ionic in aqueous solution but molecular in solvents such as benzene.

- Q: Are the aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant. Aluminum naturally forms a protective oxide layer when exposed to oxygen, which helps to prevent corrosion. This oxide layer acts as a barrier between the aluminum and the surrounding environment, making aluminum sheets highly resistant to corrosion. Additionally, aluminum sheets can be further treated with various coatings or anodizing processes to enhance their corrosion resistance even further. Therefore, aluminum sheets are a popular choice for applications where corrosion resistance is a critical requirement.

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- Aluminum wiring has caused many house fires and deaths. It is dangerous to keep using this type of wiring as it gets loose in the connections and loose electrical connections causes heat. Enough heat to melt the insulation within your walls. I have seen it. All it takes is heat and one smoldering board and your house is gone. Replace it for the safety of your family and your investment.

- Q: It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

- Q: Can aluminum sheets be plasma cut?

- Yes, aluminum sheets can be plasma cut. Plasma cutting is a versatile and efficient method that can be used to cut a wide range of materials including aluminum. By using a high-velocity jet of ionized gas, known as plasma, the aluminum sheet can be precisely cut into the desired shape. Plasma cutting offers numerous advantages such as faster cutting speeds, cleaner cuts, and minimal heat-affected zones compared to traditional cutting methods. It is commonly used in various industries such as automotive, aerospace, and construction for cutting aluminum sheets of different thicknesses.

Send your message to us

Aluminum Sheets Kansas - 1100 3003 5052 5754 5083 6061 7075 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords