Gold Aluminum Sheets - High Quality 5052 5754 5083 6061 7075 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 20-25days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

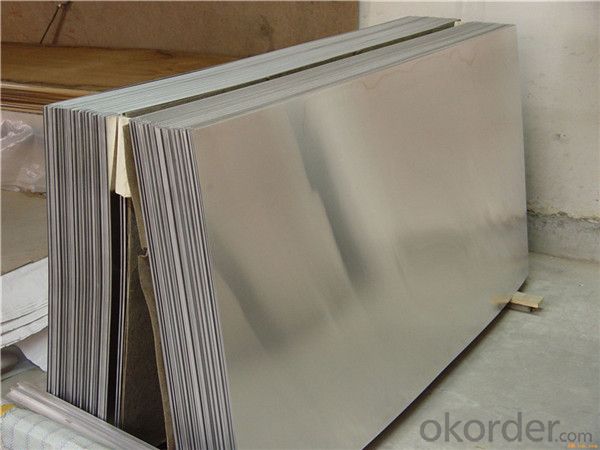

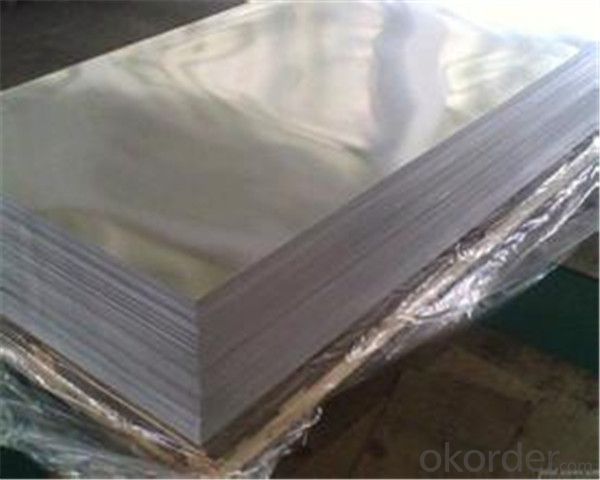

Photos

- Q: What can I do to remove the paint from the painted aluminum sheet?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.

- Q: To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- Aluminum Magnet

- Q: Can aluminum sheets be used for curtain walls?

- Certainly, curtain walls can utilize aluminum sheets. Aluminum proves to be a favored option for curtain wall systems because of its lightweight, enduring, and corrosion-resistant properties. Aluminum sheets can be effortlessly molded into different forms and dimensions, rendering them ideal for crafting the structural framework of curtain walls. Moreover, aluminum can undergo coating or anodization processes to enhance its visual appeal and offer extra safeguard against weather conditions. Consequently, aluminum sheets emerge as a versatile and pragmatic material for erecting curtain walls in both commercial and residential structures.

- Q: A dry aluminium foil paper can be bring out from oven with no burn on finger but if foil has some moisture it will result in burn why?

- The Principle behinf Microwave oven heating is that it heats up only water molecules, that is, the frequency of microwaves can only heat up water molecules ( make them oscillate and hence heat up). So if there is any trace of water or moisture on any object that you keep in the oven, it will heat up and that heat will be conducted throughout the object. Hence the foil with moisture is effectively heated whereas dry foil have no water moecule and hence will not be heated up. Hope it helps:) Can explain better if you tell me which level you are studying:)

- Q: Aluminium magnesium alloy plate, 5052 aluminium plate, 5005 aluminium plate. 5252 aluminum plate performance and use

- Material details1 and 5052 aluminum magnesium alloy aluminum plate: 5052 aluminum plate belongs to the aluminum magnesium alloy aluminum plate, the use scope is widespread, especially in the construction industry cannot leave the alloy aluminum plate, also is the most promising aluminum alloy plate. The main alloy element of 5052 aluminum plate is magnesium, which has good corrosion resistance, good weldability, cold workability and medium strength.5052 aluminum plate is commonly used in the manufacture of aircraft and car fuel tanks, oil pipes, as well as traffic vehicles, ships sheet metal parts, instruments, street lamps, brackets and rivets, hardware, electrical appliances, such as shell.2 and 5005 aluminum magnesium alloy aluminum plate: 5005 aluminum plate, band strength and 3003, welding resistance, good processing, 5005 aluminum plate and 3003 alloy similar, with moderate strength and good corrosion resistance. The anodic oxide film is more bright than the oxide film on the 3003 alloy and is in harmony with the tone of the 6063 alloy.5005 aluminum plate is often used as conductor, cooker, instrument panel, shell and building decoration, building materials, internal and external materials, vehicle materials and so on.3 and 5754 aluminum magnesium alloy aluminum sheet: 5754 aluminum alloy has the characteristics of moderate strength, good corrosion resistance, weldability and easy processing and forming. It is a typical alloy in Al Mg alloy. In foreign countries, 5754 Aluminum Alloy plates of different heat treatment condition is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry.5754 aluminum is widely used in welding structure, storage tank, pressure vessel, ship structure and marine facilities, transport tanks as well as for the requirements of good processability, excellent corrosion resistance, high fatigue strength, high solderability and moderate intensity static situations.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: What are the different methods of surface engraving aluminum sheets?

- Aluminum sheets can be surface engraved using various methods, each with its own unique advantages and suitability for different applications. One method is mechanical engraving, which involves physically removing material from the aluminum sheet using a rotating cutting tool like a milling machine or a router. This precise and versatile technique allows for intricate designs and deep engravings, making it commonly used for signage, branding, and decorative purposes. Another method is laser engraving, a modern and highly precise technique that uses a laser beam to vaporize or melt the surface of the aluminum sheet, creating a permanent mark. With great control over the depth, speed, and intensity of the engraving, laser engraving produces detailed and accurate results. It finds wide application in industries like aerospace, automotive, and electronics for part identification, serial numbers, and barcodes. Chemical etching, also known as chemical milling or photochemical machining, is a process where the aluminum sheet is coated with a photosensitive mask and exposed to UV light through a stencil or artwork. The exposed areas are then chemically etched to create the desired design. Chemical etching offers high precision, repeatability, and the ability to engrave thin lines or complex patterns. It is often used in electronic components, nameplates, and decorative applications. Diamond drag engraving involves using a diamond-tipped stylus to scratch or indent the surface of the aluminum sheet, creating the engraving. This method is commonly employed for industrial applications like part identification and serial numbering, as well as for creating durable and long-lasting markings on aluminum sheets. Lastly, rotary engraving utilizes a rotating cutting tool to remove material from the aluminum sheet, similar to mechanical engraving. However, it is typically used for larger and thicker aluminum sheets and finds application in industrial settings for marking, labeling, and identification purposes. Choosing the appropriate engraving method for aluminum sheets depends on factors such as the desired design, level of detail, durability requirements, and the intended use of the engraved product. Each method offers its own advantages and suitability for different applications.

- Q: Over the years, the thermite reaction has been used for welding railroad rails, in incendiary bombs, and to ignite solid-fuel rocket motors. The reaction is given below.Fe2O3(s) + 2 Al(s) 2 Fe(l) + Al2O3(s)What masses of iron(III) oxide and aluminum must be used to produce 10.0 g iron?a) iron (III) oxideb)aluminiumc)What is the maximum mass of aluminum oxide that could be produced?

- I'm going to show my calculations anyways Fe2O3(s) + 2 Al(s) -- 2 Fe (l) + Al2O3 (s) From the equation : 1 mole of iron (III) oxide 2 moles of aluminium -- 2 moles of iron 1 mole of aluminium oxide Given that iron = 10.0 g = 10.0 g / 55.8 g per mole = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to iron (III) oxide is 2 : 1 Therefore moles of iron (III) oxide produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (55.8 x 2 + 16.0 x 3) = 14.3 grams (corr to 3 sig fig)' a) 14.3 grams of iron (III) oxide must be used ----- Given that iron = ...... (previously calculated) ...... = 0.179 mol of iron (corr to 3 sig fig) Because the mole ratio of iron to aluminium is 1 : 1 Therefore moles of aluminium produced = 0.179 mol Convert it back to grams 0.179 x 27.0 = 4.83 grams (corr to 3 sig fig) b) 4.83 grams of aluminium must be used ----- Given that iron = 0.179 mol Because the mole ratio of iron to aluminium oxide is 2 : 1 Therefore moles of Al2O3 produced = 0.179 / 2 = 0.0895 mol Convert it back to grams 0.0895 x (27.0 x 2 + 16.0 x 3) = 9.13 grams (corr to 3 sig fig) c) 9.13 grams of aluminium oxide is the maximum mass that could be produced P.S. The relative molecular masses used are from my textbook

- Q: Can aluminum sheets be anodized for added durability?

- Indeed, it is possible to anodize aluminum sheets in order to enhance their durability. Anodization involves an electrochemical procedure that generates a protective oxide layer on the aluminum surface. This layer not only improves the material's appearance, but also boosts its ability to resist corrosion, wear, and scratches. By undergoing anodization, aluminum sheets acquire a robust, long-lasting finish, rendering them highly suitable for a range of applications that necessitate durability, including construction, automotive, aerospace, and electronics industries. Moreover, anodized aluminum sheets can be dyed in various colors, enabling them to exhibit enhanced aesthetic appeal while retaining their durability.

Send your message to us

Gold Aluminum Sheets - High Quality 5052 5754 5083 6061 7075 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords