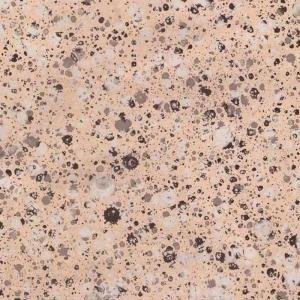

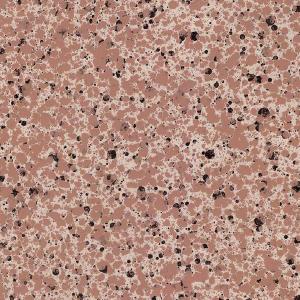

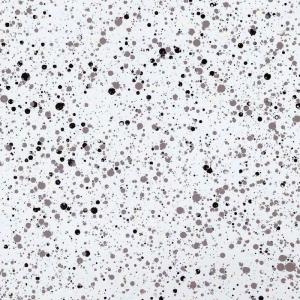

1050 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: This question asks for methods to assess the quality of aluminum coil, which is important in industries where aluminum products are used.

- <p>To check the quality of aluminum coil, you should inspect its surface for any defects like scratches, dents, or discoloration. Measure its thickness and width to ensure they meet the specified standards. Test its mechanical properties, such as tensile strength and elongation, to verify its strength and flexibility. Conduct a chemical analysis to confirm the alloy composition and purity. Check for any impurities or inclusions that could affect performance. Finally, assess the coil's flatness and straightness to ensure it's suitable for further processing.</p>

- Q: This question asks for a comparison between aluminum coil and iron coil, highlighting their distinct properties and uses.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has excellent electrical and thermal conductivity, making it ideal for electrical wiring, heat sinks, and food packaging. Iron coil, on the other hand, is heavier, stronger, and more durable, commonly used in construction, automotive, and heavy machinery due to its high tensile strength. Iron also has magnetic properties, useful in applications like transformers and electromagnets. While aluminum is non-magnetic, it is more cost-effective and has better recyclability compared to iron.</p>

- Q: What are the fire resistance properties of aluminum coils?

- Due to its unique characteristics, aluminum coils possess excellent fire resistance properties. This is primarily attributed to the metal's high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), enabling it to endure high temperatures without deforming or melting. Moreover, when exposed to air, aluminum forms a thin layer of oxide on its surface. This oxide layer acts as a protective barrier against fire and prevents further oxidation. It is worth noting that this oxide layer possesses a high melting point and is non-combustible, making it an effective fire retardant. Another advantage of aluminum is its poor heat conductivity. Consequently, it does not readily transfer heat during a fire, thus slowing down the spread of flames. As a result, aluminum coils are extensively utilized in various applications where fire resistance is a vital requirement, such as building construction, transportation, and electrical wiring.

- Q: Can aluminum coils be used in HVAC heat exchangers?

- Yes, aluminum coils can be used in HVAC heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. Aluminum coils are often used in air conditioning systems and heat pumps, where they transfer heat efficiently between the refrigerant and the surrounding air. Additionally, aluminum coils are easier to shape and form, allowing for more intricate designs and better heat transfer performance. Overall, aluminum coils are a reliable and effective choice for HVAC heat exchangers.

- Q: Can aluminum coils be used in architectural applications?

- Aluminum coils, indeed, find application in architectural projects. The construction industry frequently employs aluminum due to its adaptability, endurance, and ease of manipulation. Architects often make use of aluminum coils for roofing, cladding, and facades, thanks to their malleability in creating diverse forms and proportions. Furthermore, these coils can be coated with various finishes to improve their visual appeal and safeguard against weathering and discoloration. Ultimately, given their blend of utility, attractiveness, and durability, aluminum coils have become a favored option for architectural purposes.

- Q: What are the potential dangers associated with the use of aluminum coil?

- <p>Aluminum coil, when used in appropriate applications and handled correctly, is generally safe. However, there are some safety risks to consider: exposure to aluminum dust can cause respiratory issues, and improper handling can lead to cuts or burns. Additionally, aluminum can react with certain chemicals, potentially causing hazardous situations. It's important to use personal protective equipment and follow safety guidelines when working with aluminum coil to minimize these risks.</p>

- Q: How are aluminum coils used in the production of heat sinks?

- The excellent thermal conductivity and malleability of aluminum coils make them indispensable in the production of heat sinks. Heat sinks are designed to dissipate excess heat from electronic components like processors, integrated circuits, and power transistors. By using aluminum coils in the manufacturing of heat sinks, several key advantages can be gained. First and foremost, aluminum coils possess high thermal conductivity, enabling efficient heat transfer from electronic components to heat sinks. This is crucial for maintaining optimal operating temperatures and preventing performance degradation or permanent damage caused by excess heat. The high thermal conductivity of aluminum ensures quick dissipation of heat away from electronic components, preventing overheating. Secondly, aluminum coils are highly malleable, making them easy to shape and mold into various heat sink designs. Heat sinks come in different sizes and shapes, with the most common being finned heat sinks. Fins on the heat sink increase surface area, facilitating greater heat dissipation. Aluminum coils can be easily formed into these fin shapes, enabling effective heat release into the surrounding environment. Furthermore, aluminum coils are lightweight and corrosion-resistant, making them ideal for use in heat sinks. The lightweight nature of aluminum ensures that heat sinks do not add significant weight to electronic devices, which is especially important in applications with weight restrictions, such as aerospace or portable electronics. Moreover, the corrosion-resistant properties of aluminum guarantee the durability and longevity of heat sinks, even in harsh environments. In conclusion, aluminum coils are vital components in the production of heat sinks due to their high thermal conductivity, malleability, lightweight, and corrosion resistance. By incorporating aluminum coils into the manufacturing process of heat sinks, efficient heat dissipation and improved performance of electronic components can be achieved, ultimately extending the lifespan of electronic devices.

- Q: How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils generally offer superior durability compared to plastic coils. Aluminum is a highly durable material known for its strength and resistance to wear and tear. It can withstand heavy usage and is less likely to crack, break, or deform under pressure. On the other hand, plastic coils may be more prone to damage, especially when subjected to repetitive use or extreme temperatures. While plastic coils can be cost-effective and lightweight, they may not hold up as well over time. Therefore, if durability is a priority, aluminum coils are a better choice as they offer a longer lifespan and greater resistance to damage.

- Q: How do aluminum coils perform in high humidity environments?

- Aluminum coils perform well in high humidity environments due to their corrosion-resistant properties. The protective oxide layer on the surface of the aluminum helps prevent moisture damage, making them suitable for use in areas with high humidity levels.

- Q: How do aluminum coils contribute to noise reduction in buildings?

- Aluminum coils can contribute to noise reduction in buildings through their unique properties and installation techniques. Firstly, aluminum is a highly efficient sound insulator due to its density and ability to absorb and dampen sound waves. When used as coil insulation, aluminum can effectively block and reduce airborne noise transmission, minimizing the impact of external sounds on the building's interior. In addition to the inherent sound insulation properties of aluminum, the installation of aluminum coils in buildings can further enhance noise reduction. The coils can be strategically placed in areas where noise transmission is likely to occur, such as HVAC systems and ductwork. By tightly sealing these areas with aluminum coils, any potential gaps or openings that could allow sound to travel are eliminated. Moreover, aluminum coils can also act as a barrier to vibration and resonance noises. They can be installed around mechanical equipment or structural elements prone to vibration, effectively dampening these vibrations and preventing them from propagating throughout the building. This is particularly essential in reducing low-frequency noises, which are typically more challenging to control and can significantly impact the comfort and productivity of occupants. Furthermore, aluminum coils offer durability and longevity, ensuring their effectiveness in noise reduction over an extended period. They are resistant to corrosion, moisture, and other environmental factors, maintaining their sound-insulating properties and preventing sound leakage. Overall, by combining the sound insulation properties of aluminum with strategic installation techniques, such as sealing gaps and dampening vibrations, aluminum coils play a crucial role in reducing noise transmission in buildings. Their ability to absorb, block, and dampen sound waves makes them an effective solution for creating quieter and more comfortable indoor environments.

Send your message to us

1050 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords