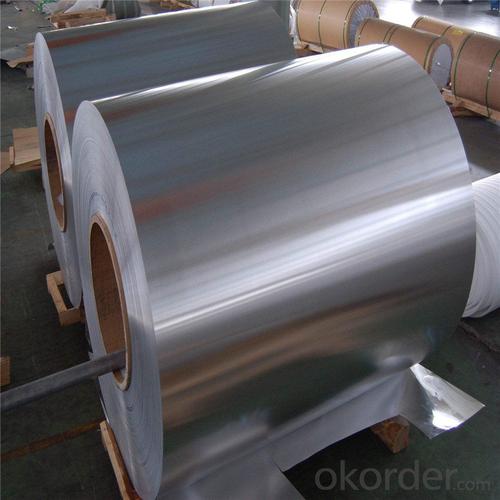

5754 Coated Aluminum Coil - 1050/1100/1070 1060 Aluminum Coil with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Coil 1060/1050/1100/1070

Chemical Composition:

| COMPOSITION % Percent | |||||||||

Si | Fe | Cu | Mn | Mg | Zn | Ti | Other elements | Al | ||

Each | Total | |||||||||

1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | 0.040 | 0.030 | 0.03 | — | 99.70 |

1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030 | 0.050 | 0.030 | 0.03 | — | 99.60 |

1050 | 0.250 | 0.400 | 0.050 | 0.050 | 0.050 | 0.050 | 0.030 | 0.03 | — | 99.50 |

1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | — | 0.100 | — | 0.05 | 0.15 | 99.00 | |

Applications:

High electro conductibility, and heat conductibility, good formability, bending and extending, commonly used for Chemical and food storage, electric conductor, soft pipe for brewing industry, heat exchanger, decoration etc.

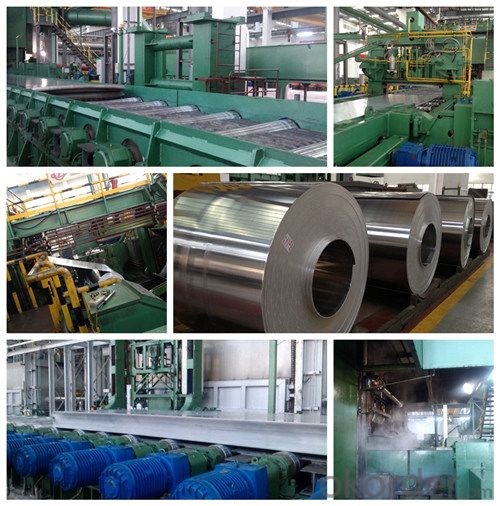

Production line:

- Q: What are the safety measures one should take when using aluminum coils indoors?

- <p>When using aluminum coils indoors, it's crucial to ensure proper ventilation to prevent the buildup of gases that can be harmful if inhaled in large quantities. Always follow the manufacturer's guidelines for installation and operation. Keep the coils away from flammable materials and ensure they are securely fastened to prevent tipping or falling. Regularly inspect the coils for any signs of damage or wear, and replace them if necessary. Never use aluminum coils in enclosed spaces without proper exhaust systems, and always have a fire extinguisher nearby in case of emergencies.</p>

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: I would like to know why the ionic substance aluminium oxide doesn't dissolve in water.

- Aluminium gives away 3 electrons, and two aluminium atoms are combined with 3 oxygen atoms, the charge is just to great for it to gracefully dissolve.

- Q: i have about 100lbs of aluminum blocks and scrap.

- There is a BIG difference between the recycling refund on aluminum containers and the scrap value of other aluminum. The recycling refund is based upon deposits on beverage containers. It used to be that scrap dealers mentioned the amount of the deposit refund PLUS the scrap value of the cans. Now many of these slimy scuzz butts only REFUND the deposit and do not pay the scrap value! They keep that scrap payment for themselves as a windfall profit! The scrap value of aluminum doors, aluminum eating utensils, and so on is a set price. You will get only scrap market value for those. It will be handled separately. Try, as I did, putting aluminum foil in the drink cans and see what happens! I was doing it only because the aluminum foil was aluminum and would go to the same place. But, they have a count scanner that assesses the number and weight of the aluminum cans you bring in (the one I went to had it mounted above the conveyer belt where the shredder accepts the cans) and they can compare the weight of all of the cans to the count or basket capacity. Also, if they find shredded aluminum foil in the bin, they can analyze approximately who brought it in. They are also wise about putting water in the cans so they are heavier, but I never did that.

- Q: This question asks whether aluminum coils can be utilized in various forms and dimensions.

- <p>Yes, aluminum coils can be used in different shapes and sizes. They are versatile and can be cut, shaped, or rolled into various forms to suit specific applications. Aluminum's malleability allows it to be easily manipulated, making it suitable for a wide range of industries, including construction, automotive, and packaging. The size of aluminum coils can also vary, from small coils used for crafts to large ones used in industrial applications. The versatility of aluminum coils makes them a popular choice for many different projects and industries.</p>

- Q: Can aluminum coils be used for radiation shielding?

- Indeed, radiation shielding can be accomplished using aluminum coils. Owing to its substantial atomic number and density, aluminum is frequently employed as a radiation shielding material, demonstrating remarkable proficiency in absorbing and dispersing radiation. It effectively safeguards against an extensive spectrum of radiation varieties, encompassing gamma rays and X-rays. Moreover, aluminum possesses the advantageous qualities of being lightweight and pliable, rendering it convenient to manipulate and appropriate for a wide range of situations necessitating radiation shielding. These encompass domains such as medical imaging, nuclear power plants, and the aerospace industry.

- Q: Are aluminum coils resistant to UV rays?

- Yes, aluminum coils are resistant to UV rays.

- Q: This question asks for methods to prevent rusting on aluminum coils during storage and transportation.

- <p>To prevent rusting on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Use a protective coating or wrapping to shield them from moisture and contaminants. Store the coils in a cool, dry place away from direct sunlight and corrosive substances. Avoid stacking them where they may come into contact with acidic materials. During transportation, secure the coils properly to prevent movement that could lead to scratches or damage. Use moisture-resistant covers to protect them from the elements. Regularly inspect the coils for signs of corrosion and address any issues promptly.</p>

- Q: This question asks about the impact of aluminum coils on the quality of welding. It seeks to understand the relationship between the material properties of aluminum coils and the outcomes of the welding process.

- <p>Aluminum coils can significantly affect welding quality due to their unique properties. Aluminum has a high thermal conductivity, which requires more energy to weld, and can lead to rapid heat dissipation, affecting the weld's uniformity. Oxides on the aluminum surface can also interfere with the welding process, causing porosity and poor joint strength if not properly cleaned. Additionally, aluminum's low melting point can lead to distortion and warping if not managed correctly. The use of appropriate filler materials, proper cleaning, and precise control of welding parameters are crucial to achieve high-quality welds with aluminum coils.</p>

- Q: Can aluminum coils be used in wastewater treatment plants?

- Yes, aluminum coils can be used in wastewater treatment plants. Aluminum coils are commonly used in heat exchangers within wastewater treatment plants to transfer heat effectively and efficiently. They are resistant to corrosion and can withstand the harsh environment of wastewater treatment processes.

Send your message to us

5754 Coated Aluminum Coil - 1050/1100/1070 1060 Aluminum Coil with Good Price and Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords