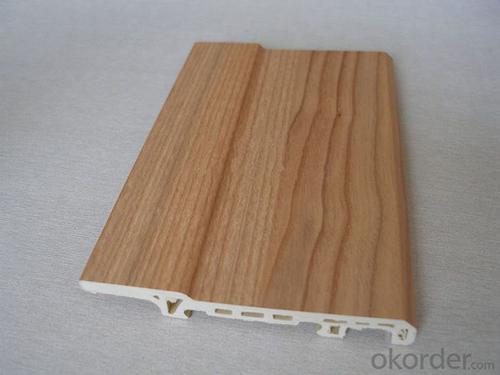

100% Recycle Environmental Friendly WPC Door Frame

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> Why choose WPC decking?

Natural colour

Resistance to water, rot and crack

Guaranteed to last

Low maintenance

Beautiful and broad range of finish

3> What are the main kinds of WPC currently?

Door frame

Wall panel

Skirting

Wardrobe door panel

Product Description

4> Specification of WPC?

Characteristics | WPC | Wood |

Moisture Resistance | Waterproof | Water absorptive |

Rot Resistance | Antisepsis | Rot except special treating |

Split Resistance | No Cracked | Cracked by weathering effect |

Distortion Resistance | Almost no Contraction/expansion | Distorting effected by chang of moisture and temperature |

UV Resistance | High Grade UV Resistance | Easily effected by UV |

Fading Resistance | Almost no | Easy to fade |

Outdoor adaptability | Great | Only few of treatedowood adaptive |

No need painting | No need | Need paint periodically |

Durable/longevity | > 8-15 years | < 3 years< span=""> |

Various Configuration | Extruded via various mould | simplex |

Environment Effect | Recyclable 100% | Consume woods |

Company Information

5> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

Our unique advantages:

Preferential payment terms

good and reasonable price

quality guarantee -- CNBM won't let a single small deal ruin our reputation and brand, so quality is

our lifetime.

professional team for CRM order processing & QA & logistics

global logistic database, originated from Dubai

Packaging & Shipping

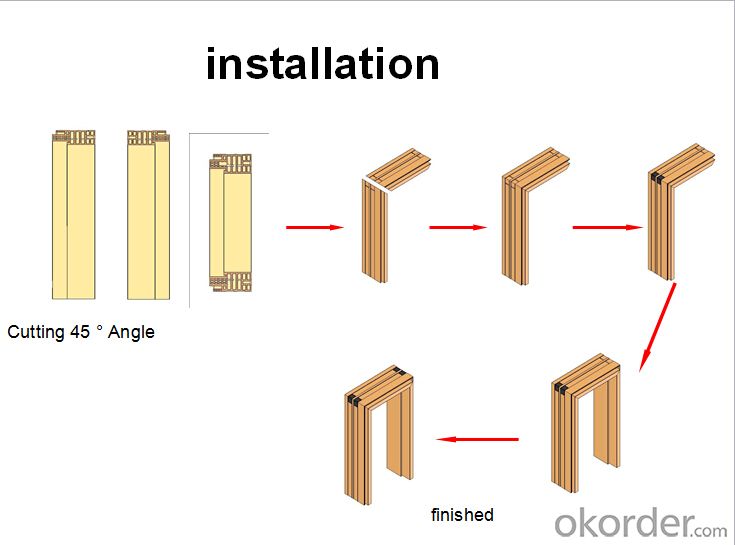

6> How to buy and concerned terms

MOQ – 800m per item

Lead time—2 weeks

Departure port—Shanghai

Package-- PE film, carton box or 2pcs.bundle, treated pallet

7> Certificates and Quality guarantee

Certificates – CE&ISO 9001 complied

Warranty—10 years

Quality guarantee—test report for each order under the strict management system

- Q: Lead alloy doors and windows of the joints how waterproof

- First, the aluminum alloy windows and doors water seepage analysis 1. doors and windows of their own water seepage 1.1 their own closed lax; 1.2 own drainage system drainage is poor; 2. doors and windows installed improperly generated cracks, resulting in seepage 2.1 windows and doors frame deformation caused by the wall with the The gap between the windows and doors and the wall between the wall of the filler is not uniform, and the resulting gap

- Q: Do the doors and windows first do the inside and outside the wall plaster?

- Sure to do the inside and outside the wall plaster, and only plaster over, in order to determine the size of the window, so as to customize the doors and windows, do not forget to stay at the door when the retaining angle.

- Q: Plastic window is how to do ah?

- Plastic co-extruded profiles to achieve the integrated production of sealing strips and profiles, significantly improved the plastic doors and windows of the watertight, air tightness and anti-aging, anti-permeability, to overcome the steel doors and windows in the production process after the sealant There are shrinking, seams and other defects, not only for the steel doors and windows assembly business to save the assembly process and time, but also reduces the cost of materials, greatly improving the production efficiency.

- Q: What is the horizontal line? How do I install windows and doors on a horizontal line?

- Horizontal line; in all rooms, the same height to find a horizontal line, before the use of horizontal tube to find points, and now with the level, infrared, when the doors and windows, doors and windows on both sides of the height parallel to the horizontal line, for example, 2 meters high door Down to the level of 1 meter, then both sides should have done 1 meter, which is the horizontal line installation

- Q: Do you want to install a seal tape for steel windows

- Some, the People's Republic of China Construction Industry Standard JG / T187-2006 Building doors and windows with sealing tape

- Q: Rough room provided by the heat of the aluminum alloy doors and windows frame color is dark green, hoping to change to white or black. Do not know what method can be achieved? 1, paint? Will it fall off? 2, see someone online that can change the color foil, do not know what kind of film? More

- Go to the building materials market to buy paint film is estimated to solve your problem

- Q: Now the management of the project in a problem, the construction of the project is to rough housing delivery to the owners, then off the bridge aluminum doors and windows need to be installed in place, then broken bridge aluminum door frame how to deal with the lower part? Is reserved in accordance with the provisions of the provisions of 5-8mm? Or first consider the owner of the renovation of about 4cm and then increase 5-8mm? Early completion of the project is in accordance with the provisions of the provisions of 5-8mm reserved for the construction, the owner of the door after the renovation of the decoration of the ground less than the ground, causing the rainy season to the indoor overflow. If you choose to increase the decoration space 4cm or so to increase 5-8mm construction, the lower part of how to deal with? More

- Broken bridge aluminum door window frame how to deal with: a large number of doors and windows before installation, should first install the sample doors and windows, after passing the acceptance, before a large number of installed. For the same type of doors and windows and their adjacent upper, lower, left and right openings should be kept line, the hole should be horizontal and vertical. Doors and windows should be placed in a clean, flat place, and to avoid sun and rain, and shall not be in contact with the corrosive; doors and windows shall not be directly touch the ground, the lower part of the placement of wood should be placed, and should be placed, vertical angle should not be less than 70 degrees , And should take anti-dumping measures. Should be measured in the middle of the window, and one by one to make a mark, multi-storey building, from a high-level hanging; installation window frame should be aligned with the center line.

- Q: My side of the wall paint 5 years of the top there are cracking the place, I want to shovel them to re-brush latex paint, but the floor of the floor I do not want to move, afraid of the construction of the workers when the workers hit bad, how can I do? Question added: the home there are a lot of furniture, it can not move, the bedroom bed closet, the living room of some have, how can I protect up ah. More

- This is simple, buy some protective film on top of it can be friends, if it is furniture can refer to the way Jiang, you can meet your needs.

- Q: What are the welding principles for steel doors and windows? Whether the vertical or vertical vertical welding, corner and doors and windows are used in what way to welding. More

- The steel frame with the doors and windows of the project that is to take dry construction, steel frame only from the middle of the connection, the steel frame with its own welding requirements are not high; but the steel frame to form a frame, horizontal or vertical length can be. Want to learn more about the doors and windows of the wall knowledge, please Google input: "Union curtain wall Forum"

- Q: Aluminum alloy doors and windows frame how to tear the film

- Highest heat treatment! Remember, do not scratch with a blade!

Send your message to us

100% Recycle Environmental Friendly WPC Door Frame

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords