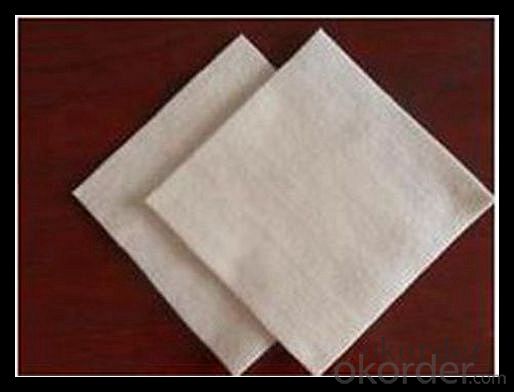

100% Polyester Filament Woven Geotextile Fabric Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

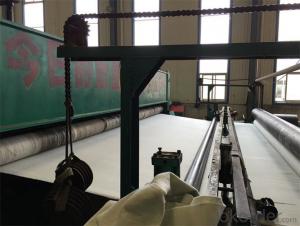

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

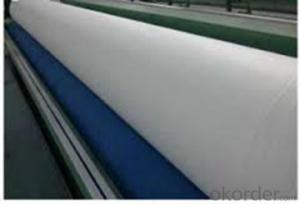

Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

Features and Benefits

Geotextiles are made from either polypropylene or polyester and geotextile fabrics come in three basic forms: woven, needle punched (resembling felt), or heat bonded (resembling ironed felt). In Australia the most popular geotextile used is the polyester needle punched fabric, as the polyester is more UV stable than the polypropylene material.

Our Service

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles aid in the reduction of liquefaction?

- Geotextiles aid in the reduction of liquefaction by providing reinforcement and stabilization to the soil during seismic events. They act as a barrier between the soil particles, increasing its strength and preventing the buildup of excess pore water pressure. This helps to maintain the soil's stability and reduces the risk of liquefaction occurring.

- Q: Can geotextiles be used in groundwater control?

- Yes, geotextiles can be used in groundwater control. Geotextiles can be employed as a filter to prevent fine particles from clogging drainage systems, as a separator to keep different soil layers distinct, or as a reinforcement to improve the stability of soil structures. In groundwater control, geotextiles are commonly used in applications such as drainage systems, erosion control, and retaining walls to effectively manage and control the movement of groundwater.

- Q: Seepage geotextile and impervious geomembrane

- Seepage geotextile is a short wire geotextile, the main thing is to filter water leakage. Impermeable geomembrane is used to waterproof, so the difference between the two is great.

- Q: Can geotextiles be used for reinforcement of bridge abutments?

- Yes, geotextiles can be used for the reinforcement of bridge abutments. Geotextiles are commonly used in civil engineering projects for soil stabilization and erosion control. When applied to bridge abutments, geotextiles can help enhance the structural integrity and stability of the soil, preventing erosion and reducing the likelihood of settlement or shifting of the abutments. By acting as a barrier between the soil and the abutment, geotextiles distribute loads more evenly, increasing the overall strength and durability of the bridge structure.

- Q: How are geotextiles used in civil engineering?

- Geotextiles are extensively used in civil engineering as a versatile material for various applications. They are commonly employed for soil stabilization, erosion control, drainage management, and reinforcement purposes. Geotextiles can be installed to prevent soil erosion on slopes, act as a separation barrier between different soil layers, provide filtration in drainage systems, and enhance the strength of embankments or roads. Their permeable nature allows for water and gas flow while effectively retaining soil particles, making them an essential component in many civil engineering projects.

- Q: We are scrambling to sell geotextiles, recommended geotextile. What is the principle of geotextile seepage? Why can geotextile seepage? More

- Geotextile impermeability depends mainly on the anti-seepage properties of plastic film. Is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: What are the different geotextile testing parameters?

- There are several different geotextile testing parameters that are used to evaluate the performance and quality of geotextiles. Some of the common parameters include tensile strength, puncture resistance, tear strength, permeability, apparent opening size, and UV resistance. These tests help determine the suitability of geotextiles for specific applications and ensure their durability and effectiveness in various geotechnical and civil engineering projects.

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. Geotextiles provide various benefits such as soil stabilization, erosion control, filtration, and drainage, making them suitable for use in underground applications like tunnels, retaining walls, and underground drainage systems. They help improve the overall performance and longevity of the underground structures.

- Q: What are the different factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. These include the intended application or function of the geotextile, the site conditions and soil characteristics, the required strength and durability, the installation and maintenance requirements, and the cost-effectiveness of the geotextile. Additionally, factors such as compatibility with other materials, environmental considerations, and regulatory requirements may also need to be taken into account.

Send your message to us

100% Polyester Filament Woven Geotextile Fabric Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords