1 2 in Aluminum Coil - Galvanized Steel Aluminum Coil in China Prime

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

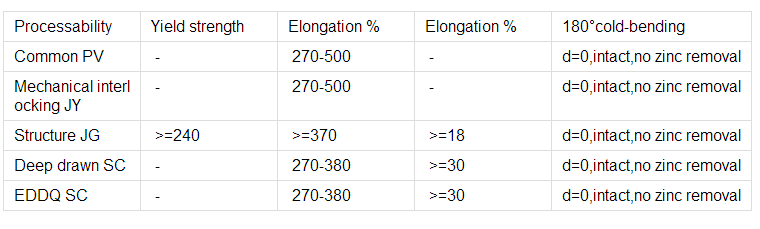

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: My dad saw an alternative medicine practioner who said he had high levels of aluminum in his blood ... from using aluminum cookware. She said this was causing the shortness of breath and dizziness he was experiencing. Since he has stopped using aluminum cookware, he is now fine. He saw regular doctors, and nobody else could figure out what was wrong with him. Has anyone else out there had any experience with this?

- Aluminum corodes very easily, especially when it's hot with water on it. It becomes aluminum oxide which , unlike aluminum, is very hard stuff and can be ground finer than talcum powder. It's not digestable so it accumulates in a body. The fine particles plug the body up, especially the lungs and small veins. Besides what you mentioned, it gets in the joints and is a terrible bearing surface. He should have a hair analysis, they'd likely find too much aluminum too. Aluminum cookware should be banned. I think it's more of a contaminate than a poison, although similar effect.

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: why is aluminum to the right side of the periodic table if it's a metal and why is it negatively charge if it's a mental. also if you combine it with like another metal will it be an ion since its positively charge or no because they are both metals

- It okorder /

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: What is the typical thermal conductivity of aluminum coils?

- Aluminum coils typically exhibit a thermal conductivity ranging from 205 to 220 W/mK. Renowned for its exceptional thermal conductivity, aluminum stands as a favored option for heat transfer purposes, notably within HVAC systems, refrigeration units, and heat exchangers. The remarkable thermal conductivity of aluminum facilitates effective dissipation and transfer of heat, thereby guaranteeing peak performance and energy efficiency in said systems.

- Q: What is the impact of alloy purity on the performance of aluminum coils?

- The impact of alloy purity on the performance of aluminum coils is significant. Higher alloy purity leads to improved conductivity, strength, and corrosion resistance of the coils. It also enhances the overall efficiency and longevity of the coils. Conversely, lower alloy purity may result in reduced performance, lower conductivity, and increased susceptibility to corrosion. Therefore, ensuring high alloy purity is crucial for maximizing the performance and durability of aluminum coils.

- Q: Is it possible to utilize an aluminum coil for heating purposes?

- <p>Yes, aluminum coil can be used as a heater. Aluminum is a good conductor of heat, making it suitable for applications where heat transfer is necessary. However, it's important to note that aluminum has a lower melting point compared to other metals like copper or steel, so it's not ideal for high-temperature applications. Aluminum coils are commonly used in electric heaters, such as toasters and air heaters, where they can efficiently transfer heat to the surrounding air or materials. Always ensure that the aluminum coil is used within safe temperature limits to prevent damage or safety hazards.</p>

- Q: This question asks for the distinctions between a single-layer aluminum coil and a multilayer aluminum coil, focusing on their structure and potential applications.

- <p>A single-layer aluminum coil consists of a single sheet of aluminum wound into a roll, while a multilayer aluminum coil is made up of multiple sheets of aluminum stacked and wound together. Single-layer coils are simpler in structure and are often used for applications requiring less complexity, such as basic insulation or simple wrapping. Multilayer coils, on the other hand, offer increased strength and can provide better insulation properties due to the multiple layers. They are also used in applications where space is limited, as they can be more compact. Additionally, multilayer coils can be tailored for specific heat transfer or electrical conductivity needs by varying the thickness and composition of the layers.</p>

- Q: i know that your not suppose to use DC for aluminum only with AC but is it possible?

- yes

- Q: does anyone know any ANTI-PERSPIRANTS that don't have any harmful chemicals such as aluminum chloride? I need something that makes you not sweat but I don't want bad chemicals in it!

- This Site Might Help You. RE: Anti-perspirant without aluminum chloride? does anyone know any ANTI-PERSPIRANTS that don't have any harmful chemicals such as aluminum chloride? I need something that makes you not sweat but I don't want bad chemicals in it!

Send your message to us

1 2 in Aluminum Coil - Galvanized Steel Aluminum Coil in China Prime

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords