Prime Cold Galvanized Steel Coil High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cold Rolled Steel Description:

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling continuous rolling, degreasing, annealing,skin pass,slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The product is widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

2.Main Features of the Cold Rolled Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Cold Rolled Steel Images

4.Cold Rolled Steel Specification

Standard:AISI,ASTM,DIN,GB,JIS,JIS G3302 ASTM 653M EN10142

Grade: Q195~Q345

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

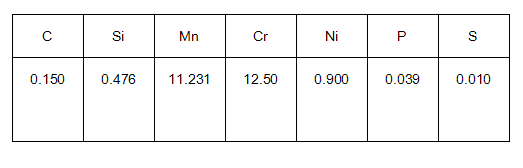

Chemical composition:

5.FAQ of Cold Rolled Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: doesnt steel rust?

- ferrous metals rust

- Q: I'v had 5 people at school say steel is stonger than Titanium and some(5) kids at school say titanium stronger then steel but i looked it up on the internet and i got soem web sites that say steel is stronger then titanium and some sites that say titanium is stonger then steel sooooo???? witch one is strongerPS i no tungsten is stronger then steel.... and titanium.................

- Titanium has better high temperature strength than steel. Titanium doesn't resist shocks like steel can. It's more brittle. It's also far more difficult to weld. Titanium must be welded in an oxygenless environment. The average strength of steels that are made is under that of titanium. However, the strongest steel is stronger than the strongest titanium. Steel is the only viable building material. Titanium is too rare, expensive, and hard to handle for structures of great height. Hope this helps. Peace and Love.

- Q: I have a 03 jeep wrangler and looking to upgrade to black wheels. I was wondering if the difference between steel and alloy wheels is worth paying double.

- steel is steel is steel- they will always be heavy you would have to weigh them to find out--NOW if you are going to alloy wheels they are typically aluminum and yes they are lighter -this is good because it lightens your un-sprung weight and is less harmful to your suspension-good for your auto

- Q: What are the dimensions of steel coils used in the pipeline industry?

- The specific application and requirements play a significant role in the variation of dimensions for steel coils utilized in the pipeline industry. Generally, the dimensions for steel coils used in this industry fall within the range of 0.5 to 3.0 inches in thickness and 24 to 60 inches in width. The length of the coils can also vary, with standard lengths typically falling between 100 and 200 feet. These dimensions are carefully chosen to ensure the necessary strength and durability for pipeline construction and the transportation of various fluids and gases. It is crucial to acknowledge that these dimensions may differ depending on the project's specifics and the standards set by the industry.

- Q: What are the factors to consider when selecting a supplier for steel coils?

- When selecting a supplier for steel coils, there are a few key factors to consider. Firstly, the quality of the steel coils is crucial. It is important to assess the supplier's reputation, certifications, and track record for delivering high-quality products. Secondly, pricing and cost-effectiveness play a significant role. Comparing prices and negotiating favorable terms with different suppliers is essential to ensure competitive pricing. Additionally, the supplier's reliability and ability to meet delivery schedules must be thoroughly evaluated. Timely delivery is vital to avoid disruptions in production. Lastly, considering the supplier's location, proximity to the manufacturing facility, and their overall customer service and support are also important factors to take into account.

- Q: How are steel coils inspected for straightness using laser alignment?

- The straightness of steel coils is examined using laser alignment technology in a precise and automated manner. This technology offers a non-contact approach to measuring the straightness of steel coils with high accuracy and efficiency. To begin with, a conveyor system is utilized to move the steel coil through the inspection area. As the coil passes through, a laser alignment system is set up to emit a laser beam across the width of the coil. This laser beam acts as a reference line for measuring straightness. The laser alignment system consists of a laser emitter and a receiver unit. The emitter projects a perfectly straight and parallel laser beam for alignment purposes. On the opposite side of the coil, the receiver unit captures the laser beam and analyzes its position. As the coil progresses through the inspection area, the receiver unit determines the deviation of the laser beam from the desired straight line. This is accomplished by analyzing the position of the laser beam at multiple points along the width of the coil. The laser alignment system is connected to a computerized control system that processes the data obtained from the receiver unit. The control system performs intricate calculations to determine the straightness of the coil based on the position of the laser beam. Any variations or deviations from the desired straight line are recorded and thoroughly examined by the control system. The inspection data can be viewed in real-time, enabling operators to monitor the straightness of the steel coil during the inspection process. The use of laser alignment technology for steel coil inspection offers numerous benefits. It provides highly precise measurements, ensuring that even slight deviations from straightness are detected. Furthermore, the non-contact nature of laser alignment eliminates the need for physical contact with the coil, thus reducing the risk of damage or contamination. Additionally, the automated process saves time and enhances efficiency compared to manual inspection methods. In conclusion, laser alignment technology is a dependable and efficient method for inspecting the straightness of steel coils. It guarantees that only coils meeting the required straightness criteria are approved, thereby contributing to the quality control of steel manufacturing processes.

- Q: Heard some steel companies like TATA Steel and JSW are in good performance. can some one suggest me if its good time to invest in steel industry ?

- I feel metal stocks can give some return now if you invest.

- Q: In terms of weight to strength titanium is stronger. But is it stronger than mild steel? If it is stronger, how much stronger is it?

- Yes ,i think so. The two most useful properties of the metal form are corrosion resistance, and the highest strength-to-weight ratio of any metal.[4] In its unalloyed condition, titanium is as strong as some steels, but 45% lighter.[5] There are two allotropic forms[6] and five naturally occurring isotopes of this element; 46Ti through 50Ti, with 48Ti being the most abundant (73.8%).[7] Titanium's properties are chemically and physically similar to zirconium.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Whilst doing a welding course a few years ago the teacher said stainless steel was not its proper name,it is called Heat and Corossion resistant steel,it come in different grades related to its corossion resistance,priced accordingly.Must be welded properly without introduction of carbon to the weld (carbon pickup) or the weld might not be there next time you look dependant on environment.Generally harder to form than mild steel (low carbon steel) so it will tend to be stronger than lcs for the same cross section.steve

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knife

Send your message to us

Prime Cold Galvanized Steel Coil High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords