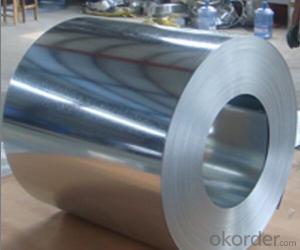

HIGH QUALITY Galvanized Steel coils FOR YOU

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

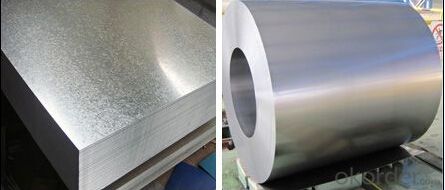

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: What are the different types of steel finishes for coil protection?

- There are several types of steel finishes used for coil protection, including galvanized, painted, and coated finishes. Galvanized steel is coated with a layer of zinc to protect against corrosion. Painted steel is coated with a layer of paint for aesthetics and additional protection. Coated finishes can include various types such as epoxy, polyurethane, or polyester, which provide different levels of durability and resistance to corrosion.

- Q: What are the main steel coil producing countries?

- The main steel coil producing countries are China, Japan, India, the United States, and Russia.

- Q: How are steel coils inspected for defects after rewinding?

- Steel coils are inspected for defects after rewinding through a thorough visual examination and various non-destructive testing techniques such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These methods help identify any surface defects, internal flaws, or deviations in dimensions, ensuring the quality and integrity of the steel coils.

- Q: What are the different coil handling equipment options available for steel coils?

- For steel coils, there are various choices available for coil handling equipment, depending on the industry's specific needs and requirements. 1. Coil Cars: Used for transporting steel coils within a facility, coil cars come with hydraulic or mechanical lifting mechanisms to safely load and unload coils onto other equipment or storage racks. 2. Coil Upenders: Essential for loading and unloading coils onto coil cars or other machinery, coil upenders rotate steel coils from a horizontal to a vertical position, or vice versa. The operation can be manual or hydraulic, depending on coil weight and size. 3. Coil Lifters: Designed for safe lifting and transportation of steel coils, coil lifters have adjustable arms or hooks that securely grip the coil's inner diameter. Depending on the coil's weight and size, coil lifters can be operated using hydraulic, mechanical, or electromagnetic mechanisms. 4. Coil Turnstiles: Coil turnstiles efficiently store and retrieve steel coils in a vertical position. They can be rotated manually or automatically using hydraulic or mechanical systems, allowing for easy access and retrieval. 5. Coil Reels: Unwinding steel coils and feeding them into processing machinery, such as stamping presses or roll forming machines, is done using coil reels. Equipped with adjustable tension controls, coil reels ensure a smooth and consistent feed. They can be operated manually or automatically, depending on the required level of automation. 6. Coil Cradles: Providing support for steel coils during storage or transportation, coil cradles evenly distribute the weight of the coil, preventing deformation or damage. They can be stationary or equipped with wheels for easy movement. In summary, the range of coil handling equipment options available for steel coils offers efficient and safe solutions for handling, storage, and processing of these heavy and valuable materials. The choice of equipment depends on factors such as coil size, weight, production volume, and specific industry requirements.

- Q: What are the different methods of surface treatment for steel coils?

- Steel coils can undergo various surface treatment methods, each with its own advantages and uses. Some commonly employed techniques include: 1. Hot-dip galvanizing: Immersing the steel coil in molten zinc results in a protective coating. This process offers excellent corrosion resistance and is commonly employed in outdoor applications like roofing, fencing, and automotive parts. 2. Electro-galvanizing: A thin layer of zinc is electroplated onto the steel coil's surface. Electro-galvanizing provides similar corrosion resistance to hot-dip galvanizing but with a thinner coating. It is often utilized when a smooth and visually appealing finish is desired, such as in appliances, electrical equipment, and automotive components. 3. Powder coating: A dry powder is applied to the steel coil's surface and cured under heat to form a durable and protective layer. This method offers excellent resistance to chipping, scratching, and fading, making it suitable for both indoor and outdoor applications. 4. Painting: Liquid paint coatings can be applied to steel coils, offering both protection and aesthetic appeal. These coatings can be customized to meet specific requirements such as corrosion resistance, UV protection, or chemical resistance. They find common usage in industries like construction, automotive, and appliances. 5. Pickling and oiling: This method involves removing scale or rust from the steel coil's surface by dipping it in an acid solution (pickling), followed by a coating of oil to prevent reoxidation. Pickling and oiling are typically employed for temporary corrosion protection during the storage and transportation of steel coils. 6. Pre-painted coatings: Steel coils can be coated with pre-painted finishes during the manufacturing stage. This continuous process involves passing the steel coil through a coating line where a layer of paint is applied. Pre-painted coatings offer a wide range of colors and finishes, making them popular in industries like construction, automotive, and appliances. These are only a few examples of the surface treatment methods commonly used for steel coils. The selection of a specific technique depends on factors such as desired corrosion resistance, aesthetic preferences, environmental conditions, and specific application requirements.

- Q: How do steel coils contribute to sustainability in construction?

- Steel coils contribute to sustainability in construction in several ways. Firstly, steel is a highly durable material that has a long lifespan. Steel coils are used in the construction of various structural components like beams, columns, and frames, ensuring the stability and strength of buildings. By using steel coils, the resulting structures require less maintenance and have a longer service life, reducing the need for frequent repairs or replacements. This durability enhances the sustainability of construction projects by reducing the overall environmental impact associated with material waste and energy consumption. Secondly, steel is a highly recyclable material. Steel coils can be easily recycled and reused in new construction projects. The recycling process of steel has a significantly lower environmental impact compared to the production of new steel. Recycling steel coils helps to conserve natural resources, reduce the extraction of raw materials, and minimize energy consumption in steel production. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Furthermore, steel is a material that can be prefabricated off-site. This means that steel coils can be manufactured in factories in a controlled environment, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces the amount of material waste generated on-site and decreases the need for transportation of construction materials, thereby reducing air pollution and energy consumption during construction. Additionally, steel is known for its high strength-to-weight ratio, which allows for lighter and more efficient structures. By using steel coils, construction projects can optimize the use of materials, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to sustainability in construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- There's no such thing as a Steel mine - steel is made from various raw materials (and now recycled metals). These materials may be mined separately and then combined at a steel mill - but steel is made, not mined. Steel, depending on what final characteristics they're trying to develop (strength, hardness, finish , etc.) can be comprised of iron, carbon, manganese, phosphorus, sulfur, nickel, chromium, etc. in varying quantities.

- Q: How are steel coils cleaned before use?

- Before being used, steel coils undergo a process called pickling to ensure their cleanliness. Pickling is a chemical treatment that eliminates impurities, scale, rust, and other contaminants from the surface of the coils. Initially, the coils are immersed in an acid bath, typically containing a mixture of hydrochloric acid and sulfuric acid. This acid solution effectively dissolves any rust, scale, and impurities present on the surface. The duration of immersion varies depending on the level of contamination and the desired level of cleanliness. After pickling, the coils undergo a thorough rinsing with water to eliminate the acid solution and any remaining residue. This step is crucial to prevent further corrosion or chemical reactions. Once rinsed, the coils are often dried to remove any remaining moisture. This can be achieved through air drying, using high-pressure air blowers, or passing the coils through heated chambers. After the cleaning process, the steel coils are now ready for use in various applications, such as manufacturing, construction, or any industry that requires high-quality steel products. The pickling process guarantees that the coils have a clean, smooth, and corrosion-resistant surface, enabling them to perform effectively and meet the desired specifications.

- Q: So...I'm learning about how steel is made and I'm wondering if there is a more environmentally friendy method. I view it as unfriendly b/c of the oxygen that is injected when the steel is in the blast furnace or electric arc furnace. This oxygen bonds w/ the carbon to produce CO and CO2. THis is necessary to reduce the amount of carbon content to produce harder steels. So what other methods are there that can be used w/o having to end up w/ co and co2? thanks

- From what I understand of it, US steel is better as the steel is more recycled than Canadian, so a lot of that oxygen / CO2 has already taken place compared to working from ore. The second reason US steel is environmentally ahead of Canadian is that US tends to use Electric Arc, while Canadian uses Basic Oxygen, Basic Oxygen uses more energy than electric arc, and I think it also uses more oxygen, but I would suspect that oxygen that it uses is 'waste oxygen' and not converted into Co2 because the Co2 process is limited by the carbon, and steel only has so much carbon.

Send your message to us

HIGH QUALITY Galvanized Steel coils FOR YOU

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords