0.75kw 3 phase 380v ac variable frequency drive for motor

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 300 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Brand:CHINSC

2.Motor KW:160kw

3.MOQ:1 set

4.Good price&quality

1. Application

Textiles, Plastics, Ceramics, Electronics, Numerical Controls, Foods Processing, Light Industry, And Pharmaceuticals. Oil, mining and other fields.

2. Technical Specification

Item | Description | |

Input Power Supply | Rated voltage | standard:380v Nonstandard: 660v, 1140v, common DC bus ,DC power supply to customize. |

Number of phases and frequency | 3-phase 50/60Hz(refer to rated current specification) | |

Range | Voltage:-15%~20%,frequency:±5%Hz | |

Power Capacity | If Power capacity is more than ten times of the drive capacity, please purchase input reactor components. | |

Output Power Supply | Rated Capacity/Current | Please refer to table2-1 |

Over load ability | Type G: 150% rated current for 1 minute, 180% rated current for 1 second; Type P: 120% rated current for 1 minute, 150% rated current for 1 second. | |

Cooling | Cooling | Forced Cooling |

Temperature | 80°C trip | |

Fan control | Heatsink temperature> 50°C continuous operation | |

Main control functions | control mode | No sense of vector control, V/F control, Torque Control |

Output frequency range | 0.1-600 Hz | |

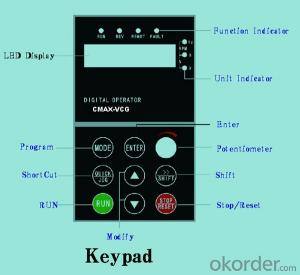

Frequency resolution | Keypad setting:0.01Hz; Analog setting: 0.1Hz | |

Frequency Accuracy | Keypad setting: highest output frequency ±0.01%; Analog setting: max output frequency ±0.2% | |

Frequency | 0.5-600Hz | |

Braking | 15KW and below, with a brake unit, 18.5KW above need to connect an external braking unit. | |

DC injection braking | Brake Voltage: 0~150% rated current adjustable, allowing the 0Hz~maxmin frequency braking, time :1~50seconds adjustable. | |

Acc/Dec time | 0.1~3600.0s | |

Low-frequency torque compensation | Manuel or automatic compensation | |

Distance | If the wiring distance is more than 50m between the drive and the motor wiring, please install output reactor components | |

Motor overheating detection | Trips and shows E016 | |

Standard functions | Speed tracking, paused reducer, PID control, automatic speed compensation, automatically adjusts voltage output (AVR), 16 segment speed operation, torque control, frequency hopping, torque limiting, automatic multi-stage operation, U(-)SPwn control, pendulum frequency operation, two signals superimposed control, automatic reset, timer. | |

Standard control signals | Analog input | Two groups of external analog inputs: 0~5V, 0 or 4~20mA. Two groups of analog inputs 0~1A. Keypad potentiometer input (0~5V). |

Analog output | Two programmable analog output (0~10V) or (0~20mA) | |

Digital input | Six groups of programmable open collector inputs | |

Digital output | One programmable open collector output, Two set of programmable relay outputs. | |

Communication Interface | Sequence communication | Sequence communication Options included, can be unified through multiple (up to 99 units) dynamic control. |

Communication protocol | Standard MODBUS | |

Communication port | RS485 | |

Display | Seven-Segment Display | Output current, output power, input power, power factor, the timer time, the heat sink temperature. |

Threshold of overload cumulative, the output power limit, the output frequency, speed conversion, DC bus voltage, output voltage and temperature. | ||

Protection |

Standard function | Over current, overload, short circuit protection, over voltage, Under voltage protection; Over heat protection; ground fault, input failure phase, output failure phase, the motor overheated. |

Environment | Ambient temperature | -10°C~+40°C(ambient temperature is within 40°C~50°C, deration is required),free from direct sunlight. |

Humidity | Less than 95%RH, without condensation | |

Application environment | Non-corrosive, flammable, explosive, dust absorbent material, all kinds of lint does not accumulate. | |

Vibration | Less than0.6G | |

Elevation | Lower than 1000m,if exceed this value, deration is required. | |

Storage temperature | -20~60°C | |

3. Company Introduction

Certification

- Q: A 4-pole AC motor into a 2-pole AC motor, the motor is controlled by the inverter, to make the maximum speed of the 2-pole motor and the original 4-pole

- The upper limit frequency transferred to 25HZ, the number of poles changed to 2, try to run when the motor speed test

- Q: Laptop power adapter current is not the same alternative?

- The adapter is the voltage source, the actual output current depends on the size of the load resistance,

- Q: My Lenovo v450 laptop power adapter should be bad how to match?

- In order to ensure quality, we recommend that you buy genuine, you can contact the service station to buy engineers

- Q: How does the variable frequency motor output torque at very low frequencies?

- 1, to improve the slip of the inverter compensation coefficient 2, to improve the continuous lifting coefficient of the inverter, but the coefficient is too high there will be overcurrent. 3, with no sensor vector control can increase the motor output torque or encoder with the vector control can make the motor at low frequency to achieve the rated output torque.

- Q: Inverter problem

- (0 ~ 20mA), but the main input / output is completely isolated, than the output of the inverter simulation of the output of the analog output The amount of signal impact resistance, anti-interference ability.

- Q: What is the adapter?

- An adapter is a physical device that allows a hardware or electronic interface to interface with another hardware or electronic interface (adapt and without any loss).

- Q: 22kw.2 pole fan can use Fuji inverter?

- Definitely yes. 2-pole motor and four-pole motor difference is: the current is different, the speed is different, the torque is not the same,

- Q: Is the number of Amps of the notebook power adapter higher than the original number of security on the computer?

- The current amperage of the power adapter is only experienced at its maximum output power, as long as the power adapter output voltage and your original no problem. For example, when the home circuit from the power supply into the terminal does not limit the size of the current, but to provide a fixed voltage. The more your household appliances, the greater the current through the power supply into your home. And the indoor air break switch is a current limit, this is based on the ability to accept the wire. From the point of view of the meter, you use the power equal to UIt = W, where UI is the voltage and current, two multiplication is equal to power, power multiplied by time equal to power consumption. Say back to your power adapter, the power adapter output voltage is rated, as long as this notebook with your original output voltage is the same as your notebook will not hurt. And the power adapter current is the maximum output, the consciousness is the power adapter output maximum power P will not exceed this value, usually 65W or 90W. Greater than the power of such a computer can not be stable operation. Or a physical point of view, the use of notebook power adapter, in fact, the internal is a number of parallel circuits, secondary knowledge tells us the voltage of the parallel circuit at any end are the same size, and parallel devices, the greater the total current in the circuit The

- Q: The inverter flat rate transferred to 29, on the submersible pump to burn the coil ?!

- 4, high-speed motor: high-speed motor running process will produce a large number of harmonics, enhance the output current of the inverter, resulting in a lot of heat. Therefore, the inverter selection is also larger than the ordinary one gear. 5, explosion-proof motor: In some mines, oil extraction environment, the frequency conversion system is explosion-proof motor, the choice of inverter should use the explosion-proof function of the inverter, and the inverter placed in a safer place. 6, the degree of protection: for dust, wet applications, inverter selection should pay attention to its protection level. Or choose Ampang letter AMB inverter, the fan can also run in the water. 7, single-phase motor: When the scene using single-phase motor, the inverter useless. 8, variable pole motor: When the field using variable pole motor, the inverter selection should ensure that the maximum operating current should not exceed the rated current of the inverter

- Q: Three motors, if coupled with the governor speed, is it necessary to add the inverter?

- ?Fourth, the electromagnetic speed: electromagnetic speed motor by the cage motor, electromagnetic slip clutch and DC excitation power. DC excitation power is small, usually by single-phase half-wave or full-wave thyristor rectifier composition, change the thyristor conduction angle, you can change the size of the excitation current.

Send your message to us

0.75kw 3 phase 380v ac variable frequency drive for motor

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 kg

- Supply Capability:

- 300 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches